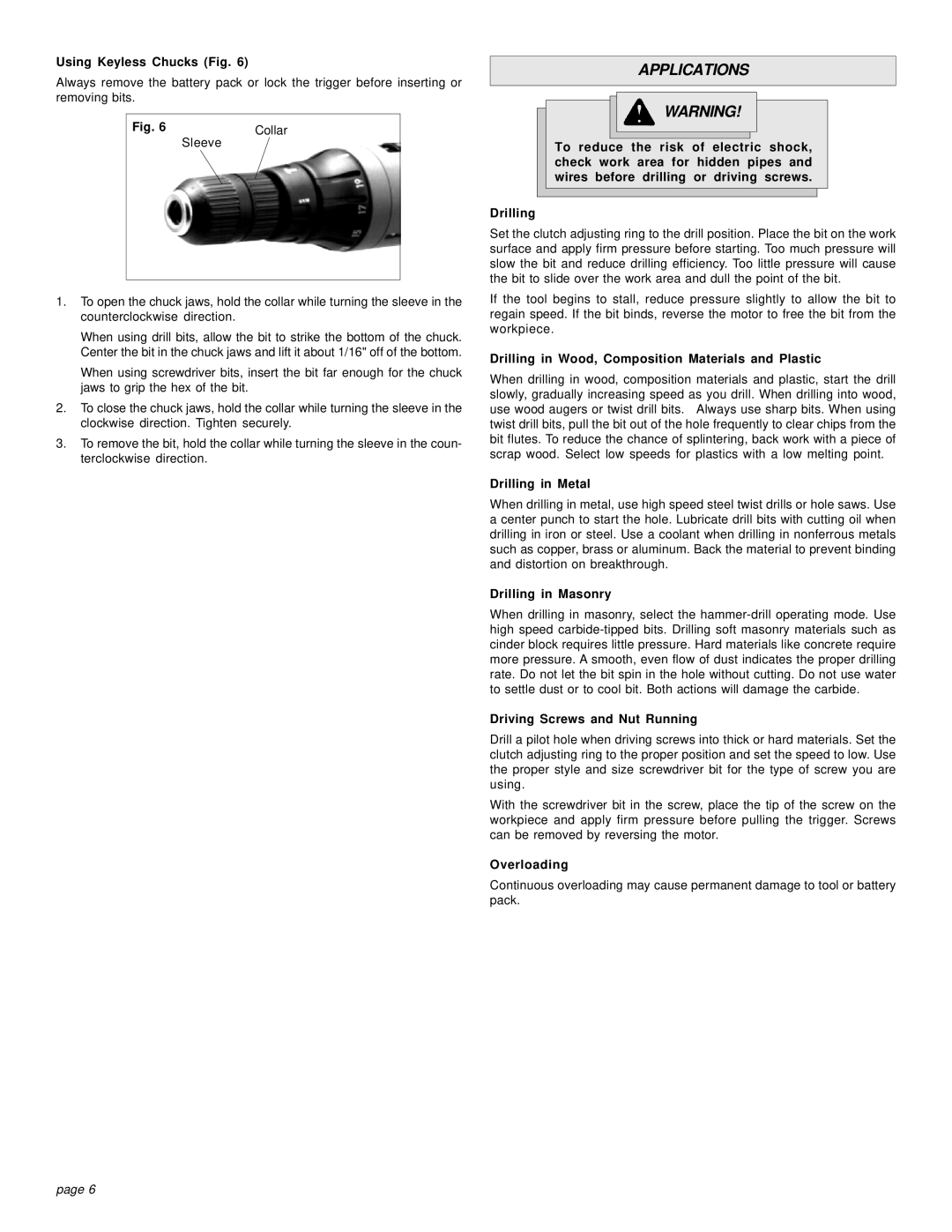

Using Keyless Chucks (Fig. 6)

Always remove the battery pack or lock the trigger before inserting or removing bits.

Fig. 6 | Collar |

| Sleeve |

1.To open the chuck jaws, hold the collar while turning the sleeve in the counterclockwise direction.

When using drill bits, allow the bit to strike the bottom of the chuck. Center the bit in the chuck jaws and lift it about 1/16" off of the bottom.

When using screwdriver bits, insert the bit far enough for the chuck jaws to grip the hex of the bit.

2.To close the chuck jaws, hold the collar while turning the sleeve in the clockwise direction. Tighten securely.

3.To remove the bit, hold the collar while turning the sleeve in the coun- terclockwise direction.

APPLICATIONS

WARNING!

To reduce the risk of electric shock, check work area for hidden pipes and wires before drilling or driving screws.

Drilling

Set the clutch adjusting ring to the drill position. Place the bit on the work surface and apply firm pressure before starting. Too much pressure will slow the bit and reduce drilling efficiency. Too little pressure will cause the bit to slide over the work area and dull the point of the bit.

If the tool begins to stall, reduce pressure slightly to allow the bit to regain speed. If the bit binds, reverse the motor to free the bit from the workpiece.

Drilling in Wood, Composition Materials and Plastic

When drilling in wood, composition materials and plastic, start the drill slowly, gradually increasing speed as you drill. When drilling into wood, use wood augers or twist drill bits. Always use sharp bits. When using twist drill bits, pull the bit out of the hole frequently to clear chips from the bit flutes. To reduce the chance of splintering, back work with a piece of scrap wood. Select low speeds for plastics with a low melting point.

Drilling in Metal

When drilling in metal, use high speed steel twist drills or hole saws. Use a center punch to start the hole. Lubricate drill bits with cutting oil when drilling in iron or steel. Use a coolant when drilling in nonferrous metals such as copper, brass or aluminum. Back the material to prevent binding and distortion on breakthrough.

Drilling in Masonry

When drilling in masonry, select the

Driving Screws and Nut Running

Drill a pilot hole when driving screws into thick or hard materials. Set the clutch adjusting ring to the proper position and set the speed to low. Use the proper style and size screwdriver bit for the type of screw you are using.

With the screwdriver bit in the screw, place the tip of the screw on the workpiece and apply firm pressure before pulling the trigger. Screws can be removed by reversing the motor.

Overloading

Continuous overloading may cause permanent damage to tool or battery pack.

page 6