Briggs & Stratton Power Products Home Generator

Installation Manual

![]() DANGER

DANGER

Storage batteries give off explosive hydrogen gas during recharging.

Slightest spark will ignite hydrogen and cause explosion.

Battery electrolyte fluid contains acid and is extremely caustic.

Contact with battery contents will cause severe chemical burns.

A battery presents a risk of electrical shock and high short circuit current.

•DO NOT dispose of battery in a fire.

•DO NOT allow any open flame, spark, heat, or lit cigarette during and for several minutes after charging a battery.

•DO NOT open or mutilate the battery.

•Wear protective goggles, rubber apron, and rubber gloves.

•Remove watches, rings, or other metal objects.

•Use tools with insulated handles.

4.Connect the red battery cable to the battery positive terminal (indicated by POSITIVE, POS, or (+).

5.Connect the negative battery cable to the negitive battery terminal (indicated by NEGATIVE, NEG, or

6.Ensure hardware on both positive and negative battery terminals is secure.

7.Reinstall the 15 Amp fuse in the control panel.

![]() CAUTION

CAUTION

Installing the 15A fuse could cause the engine to start.

•DO NOT install the 15 Amp fuse until all plumbing and wiring has been completed and inspected.

8.Set the generator's “AUTO/OFF/MANUAL” switch to AUTO.

NOTE: With the battery installed and utility power available to the Automatic Transfer Switch, the battery receives a trickle charge whenever the engine is not running.The trickle charge only prevents

Fuel Supply System

Ensure that all fuel pipe connections are tight, secure and without leaks.

Ensure that all gas line shutoff valves are OPEN and that adequate fuel pressure is available whenever automatic operation is desired.

FUEL SYSTEM SELECTION

The engine of your Home Standby Generator is factory calibrated to run on natural gas (NG). It may also be operated on liquefied petroleum (LP).There is no additional hardware/equipment required to switch between either fuel. However, LP fuel inlet pressure must be between

11 and 14 inches water column.

To configure the fuel system for LP use:

•Set the AUTO/OFF/MANUAL switch to OFF.

•Remove the 15 Amp fuse.

•Connect the fuel transfer solenoid as follows:

1.Remove the “Oil Service” access door.

2.Join the

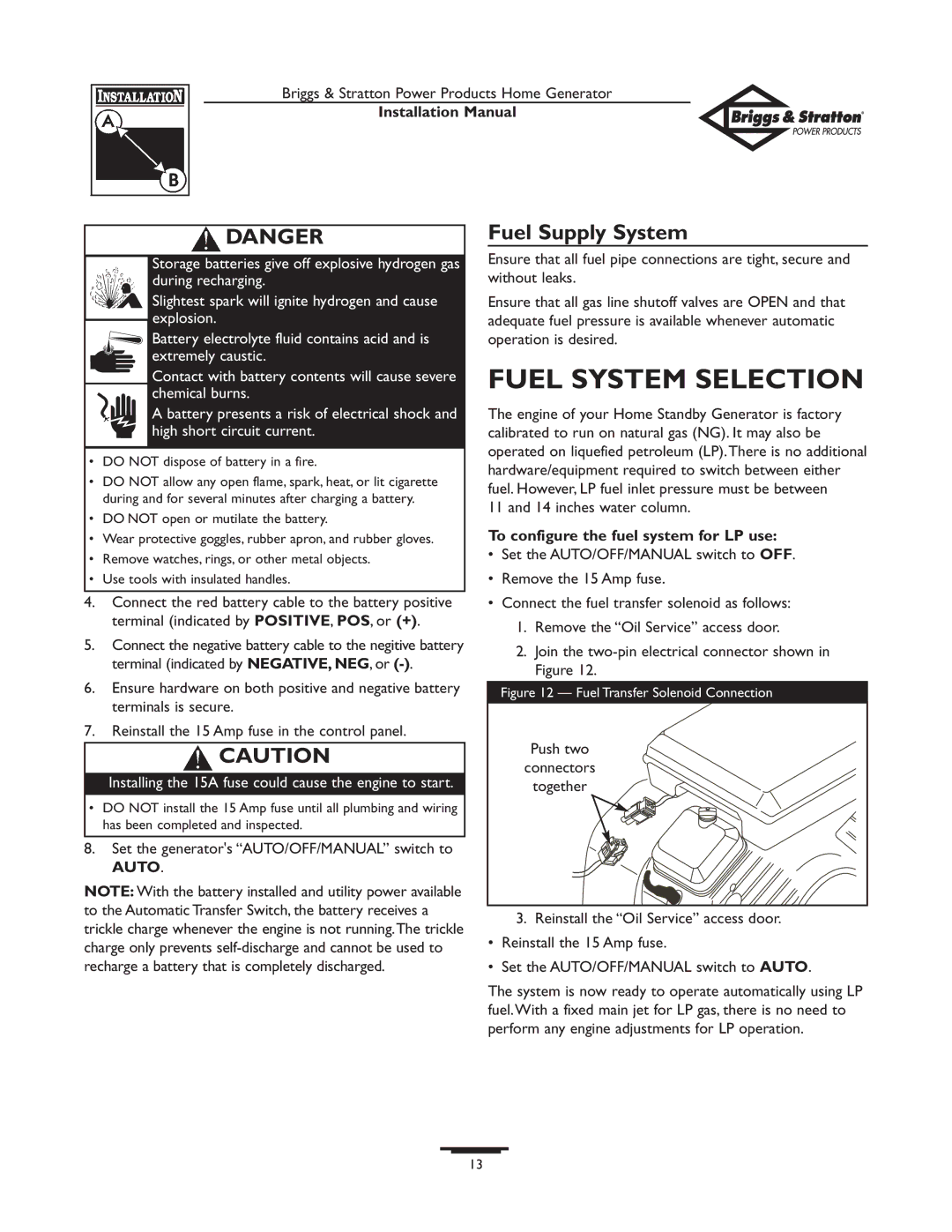

Figure 12 — Fuel Transfer Solenoid Connection

Push two

connectors

together

3.Reinstall the “Oil Service” access door.

•Reinstall the 15 Amp fuse.

•Set the AUTO/OFF/MANUAL switch to AUTO.

The system is now ready to operate automatically using LP fuel.With a fixed main jet for LP gas, there is no need to perform any engine adjustments for LP operation.

13