Briggs & Stratton Power Products Home Generator

Installation Manual

•Install the unit outdoors ONLY.

•Place the unit in a prepared location that is flat and has provisions for water drainage.

•Install the unit where air inlet and outlet openings will not become obstructed by leaves, grass, snow, etc. If prevailing winds will cause blowing or drifting, you may need to construct a windbreak to protect the unit.

•Install the generator as close as possible to the Transfer Switch to reduce the length of wiring and conduit.

•Install the generator as close as possible to the fuel supply to reduce length of pipes.

IMPORTANT: Laws or local codes may regulate the distance to the fuel supply.

The Home Standby Generator is shipped already attached to its mounting pad. Unless mandated by local code, a concrete slab is not required.

If mandated by local code, construct a concrete slab at least 3 inches thick and 6 inches longer and wider than the unit. Attach unit to slab with 1/4” diameter (minimum) masonry anchor bolts long enough to retain the unit.

Fuel and Electrical Inlet Dimensions

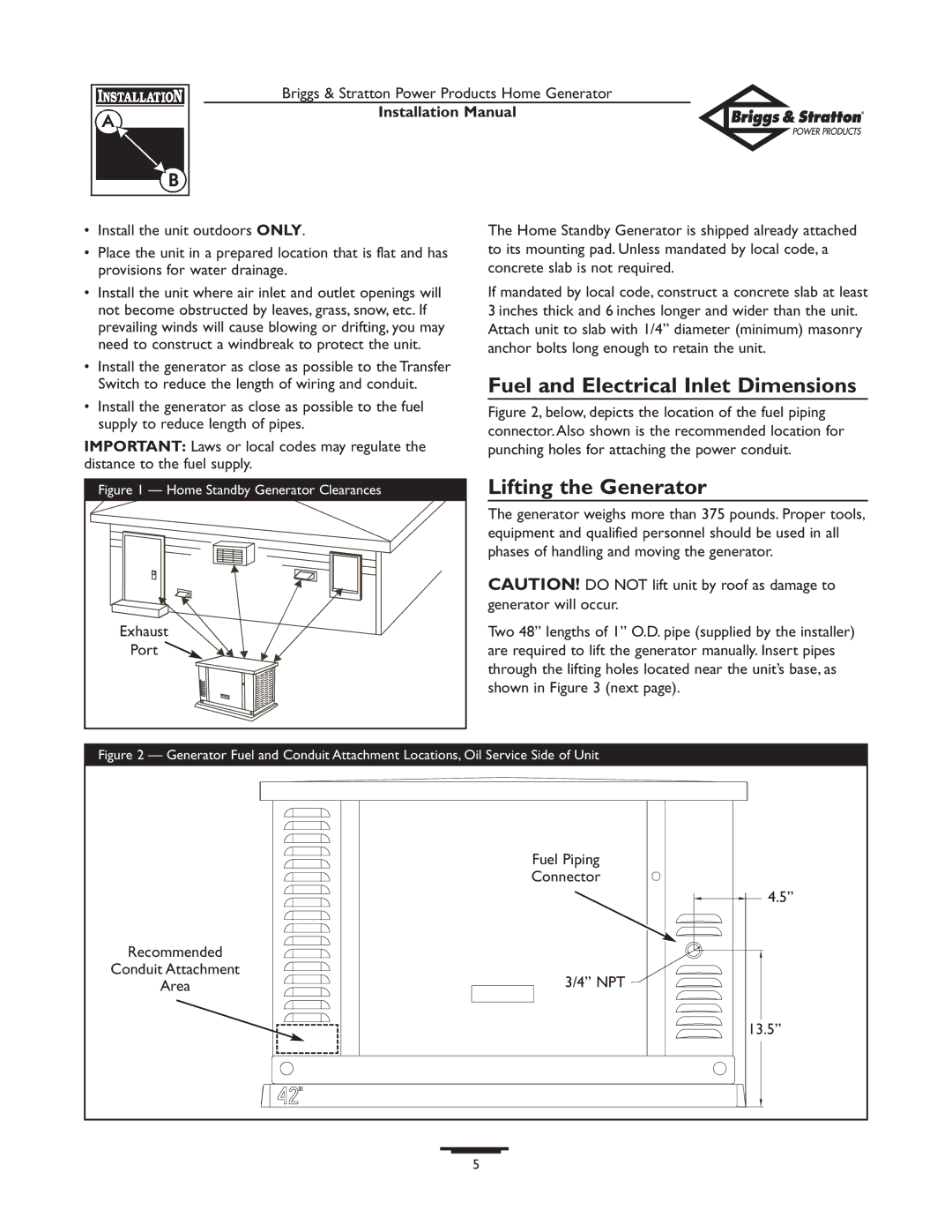

Figure 2, below, depicts the location of the fuel piping connector. Also shown is the recommended location for punching holes for attaching the power conduit.

Figure 1 — Home Standby Generator Clearances

Exhaust |

Port |

Lifting the Generator

The generator weighs more than 375 pounds. Proper tools, equipment and qualified personnel should be used in all phases of handling and moving the generator.

CAUTION! DO NOT lift unit by roof as damage to generator will occur.

Two 48” lengths of 1” O.D. pipe (supplied by the installer) are required to lift the generator manually. Insert pipes through the lifting holes located near the unit’s base, as shown in Figure 3 (next page).

Figure 2 — Generator Fuel and Conduit Attachment Locations, Oil Service Side of Unit

Fuel Piping

Connector

4.5”

Recommended |

|

Conduit Attachment | 3/4” NPT |

Area |

13.5”

5