10.Start engine following instructions How to Start Your Pressure Washer.

11.Test pressure washer by operating with each quick connect spray tip.

O-Ring Maintenance

Purchase an

![]() WARNING

WARNING

The high pressure stream of water that this equipment produces can cut through skin and its

![]() underlying tissues, leading to serious injury and possible amputation.

underlying tissues, leading to serious injury and possible amputation.

•NEVER repair leaking connections with sealant of any kind. Replace

Pump Oil Maintenance

Changing Pump Oil

Change oil after first 50 hours of operation and then every 200 hours or 3 months, whichever occurs first.

NOTE: When changing pump oil, use only high quality nondetergent 30 weight oil. Use no special additives.

Change pump oil as follows:

1.Clean area around brass oil drain plug at bottom of pump.

2.Remove oil drain plug. Drain oil completely into an approved container.

3.When oil has completely drained, install oil drain plug and tighten firmly.

4.Clean area around pump oil dipstick. Remove dipstick and fill pump with recommended oil (approximately 9.6 oz.) to “Full” mark on dipstick.

5.Install pump oil dipstick.

6.Wipe up any spilled oil.

Engine Maintenance

![]() WARNING

WARNING

Unintentional sparking can result in fire or electric shock.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR PRESSURE WASHER

•Disconnect the spark plug wire from the spark plug and place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

•Use approved spark plug tester.

•DO NOT check for spark with spark plug removed.

Oil

Oil Recommendations

NOTE: Use a high quality detergent oil classified “For Service SF, SG, SH, SJ” or higher. DO NOT use special additives.

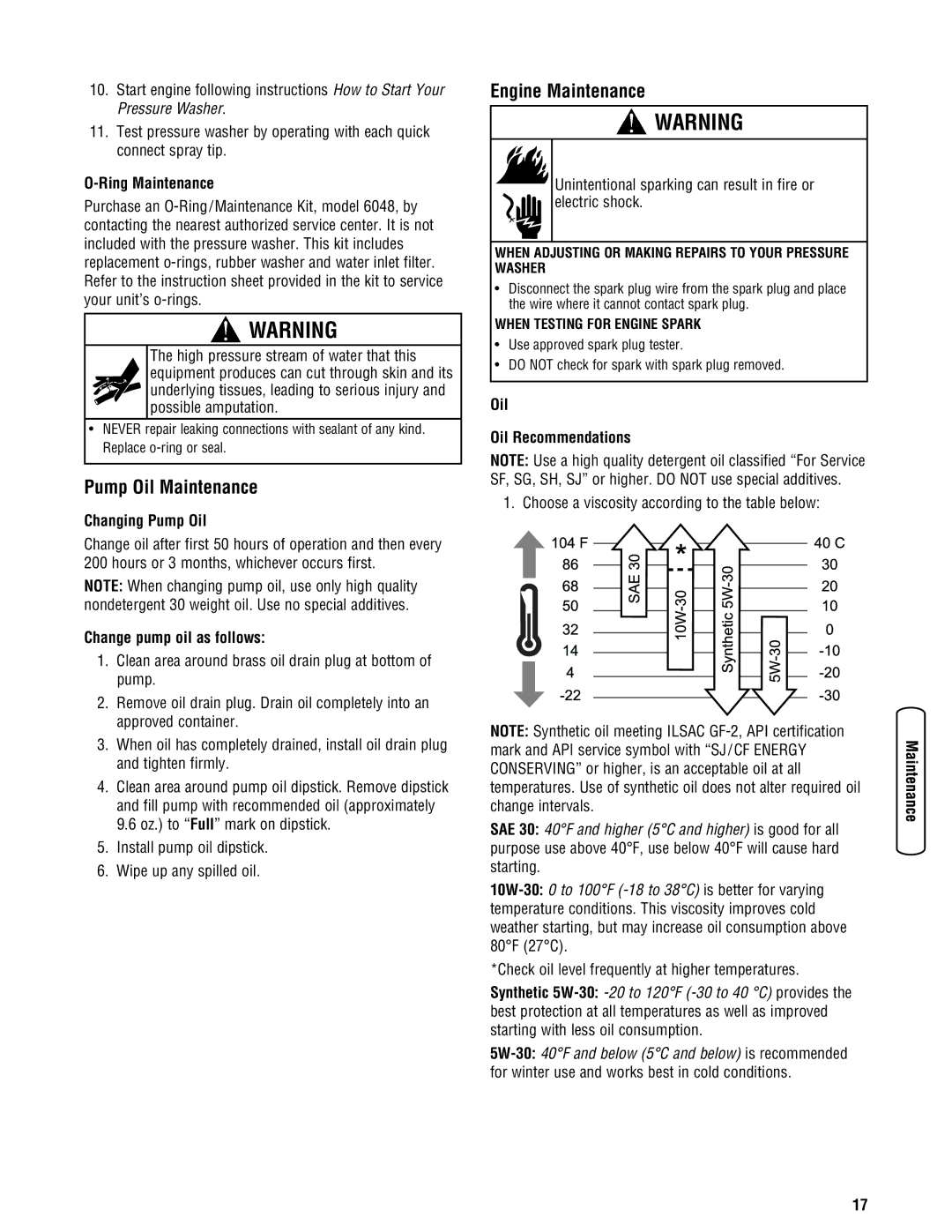

1. Choose a viscosity according to the table below:

NOTE: Synthetic oil meeting ILSAC

SAE 30: 40°F and higher (5°C and higher) is good for all purpose use above 40°F, use below 40°F will cause hard starting.

*Check oil level frequently at higher temperatures.

Synthetic

17