030319, 030320 specifications

Briggs & Stratton has been a trusted name in the power equipment industry for over a century, and their 030320 and 030319 models are perfect examples of their commitment to quality and innovation. These engines are designed to power a variety of outdoor equipment, including lawn mowers, generators, and pressure washers, making them a versatile choice for homeowners and professionals alike.One of the main features of the Briggs & Stratton 030320 and 030319 engines is their impressive power output. The 030320 model boasts a robust 550cc displacement, while the 030319 offers a slightly lower 450cc. This power enables these engines to tackle demanding tasks with ease, ensuring that users can complete their projects efficiently and effectively.

Both models are equipped with advanced technologies that enhance performance and reliability. The ReadyStart system allows for effortless starting without the need to prime or choke the engine, significantly reducing the time spent preparing the equipment for use. Additionally, the engines feature a durable overhead valve (OHV) design, which promotes better fuel efficiency and reduced emissions compared to traditional side-valve engines.

Another key characteristic of the Briggs & Stratton 030320 and 030319 engines is their robust construction. They are built with high-quality materials, which provide durability and longevity, making them suitable for heavy-duty applications. The engines also feature a steel crankshaft that withstands high-stress conditions and a cast iron sleeve for improved wear resistance.

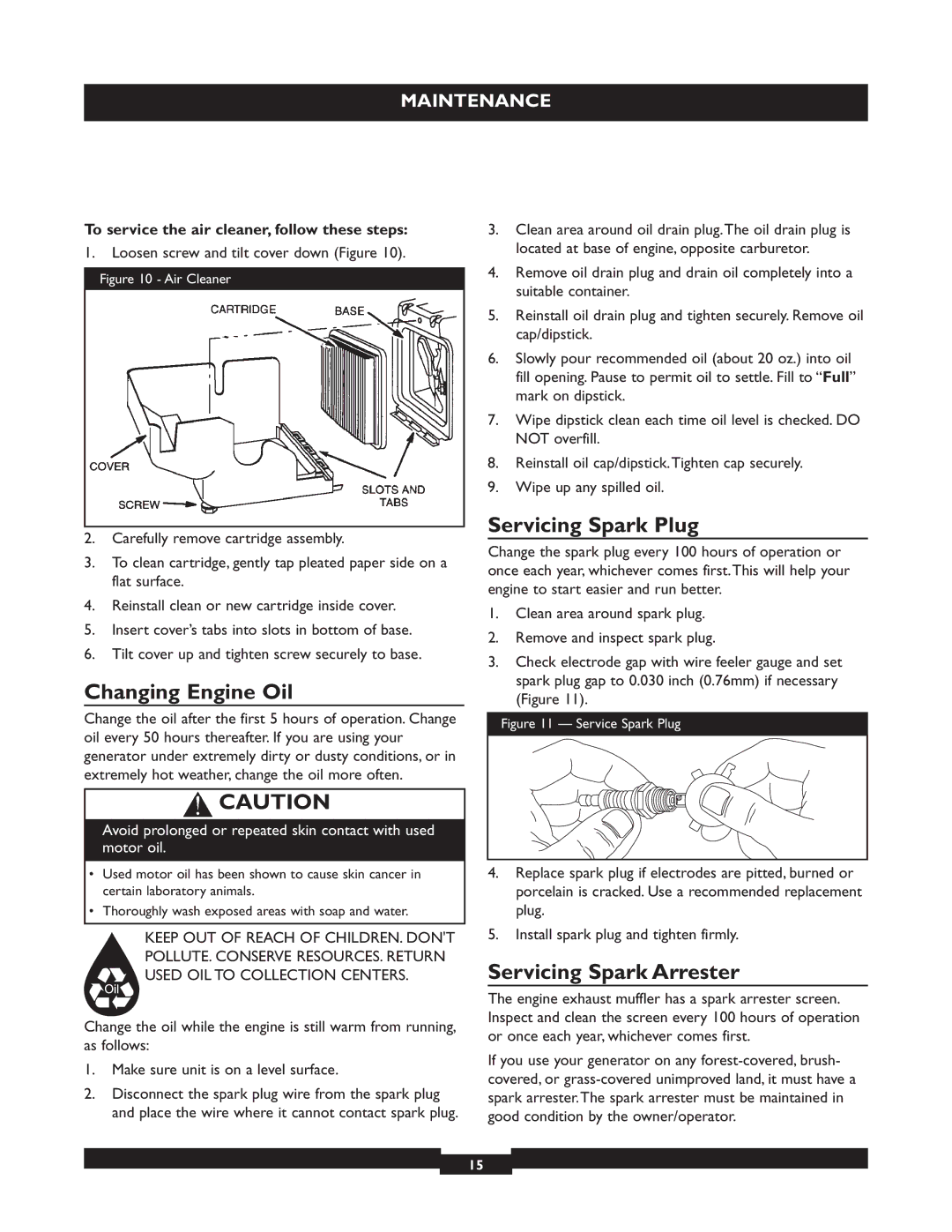

Maintenance is made easy with these engines, thanks to their accessible oil drain and air filter design. Users can quickly change the oil and replace the air filter, ensuring that the engine functions at peak performance over time. This focus on user-friendly maintenance makes the 030320 and 030319 models ideal for individuals who want reliable performance without the hassle of complicated upkeep.

Safety is also a priority in the design of these engines. They come equipped with features such as a low-oil shutdown system that automatically turns off the engine when oil levels drop too low, preventing potential damage. This added layer of protection ensures that users can operate their equipment with peace of mind.

In summary, the Briggs & Stratton 030320 and 030319 engines combine power, efficiency, durability, and user-friendly features. Whether you are a homeowner tackling seasonal yard work or a professional in need of reliable equipment, these engines deliver exceptional performance and reliability, solidifying Briggs & Stratton’s reputation as a leader in the industry.