Electric Pressure Washer specifications

Briggs & Stratton has become a well-known name in the world of outdoor power equipment, and their electric pressure washer is a prime example of innovation and efficiency in cleaning technology. Designed to tackle a variety of cleaning tasks, this electric pressure washer combines ease of use, portability, and impressive performance, making it a favored choice among homeowners and DIY enthusiasts.One of the standout features of the Briggs & Stratton Electric Pressure Washer is its powerful motor, which delivers a robust cleaning force without the need for gasoline. With pressure ratings of up to 2,000 PSI, it efficiently removes dirt, grime, and stains from surfaces such as driveways, decks, siding, and patios. The electric nature also means reduced maintenance; there are no oil changes or air filter replacements.

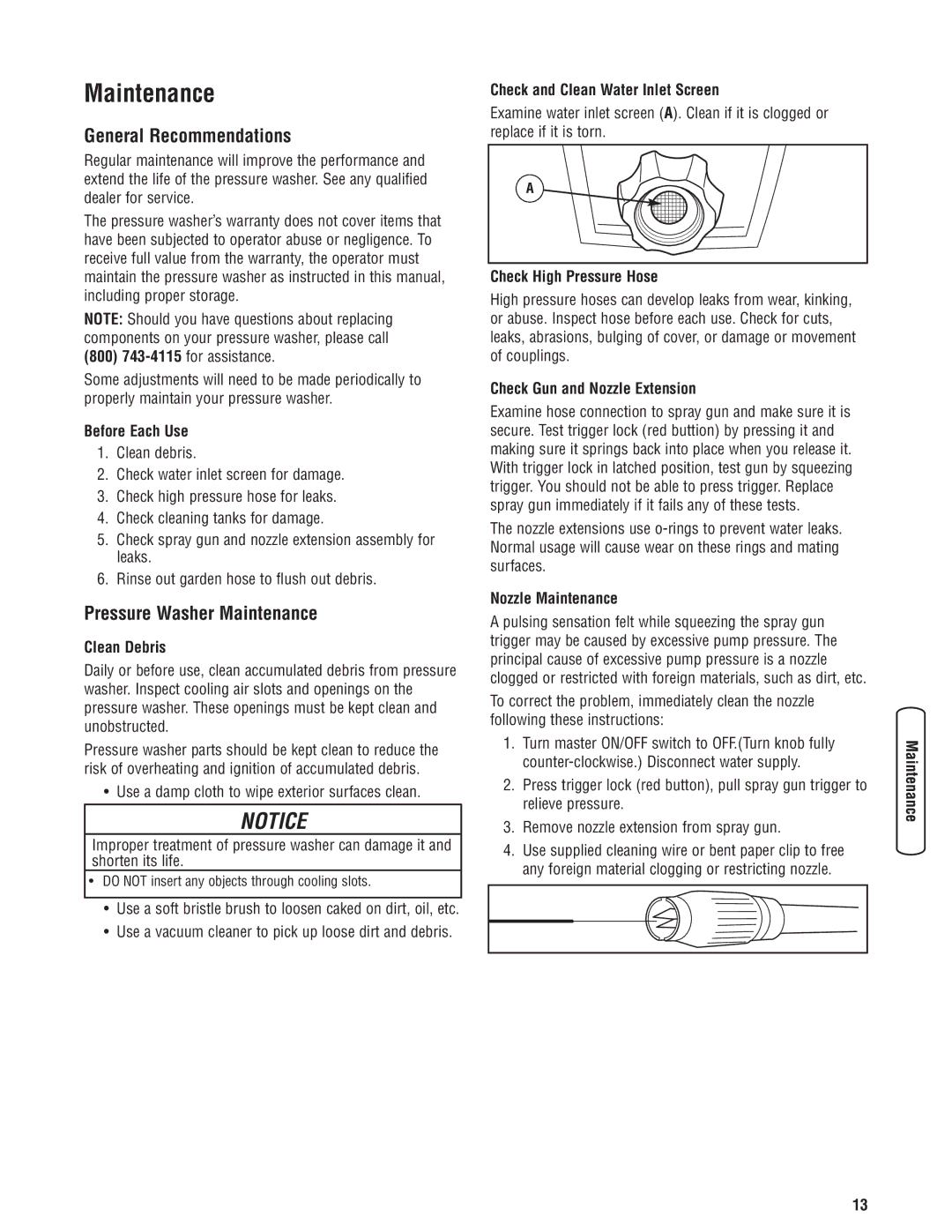

Equipped with a user-friendly design, this pressure washer includes an adjustable nozzle that allows users to switch between different spray patterns for various applications. Whether it’s a gentle rinse for delicate surfaces or a focused jet to tackle tough stains, the versatility of the nozzle is a significant advantage. Many models also feature onboard storage for attachments, ensuring that hose connections and cleaning accessories are always within reach.

Another key characteristic of the Briggs & Stratton Electric Pressure Washer is its lightweight and compact design, making it easy to transport. Its solid wheels ensure smooth movement across different terrains, removing the hassle of maneuvering a bulky machine during cleaning projects.

Incorporating advanced technologies, the pressure washer is compatible with various cleaning detergents to enhance cleaning power. Innovative features, like the integrated soap dispenser, allow for more effective cleaning without damaging surfaces. The overall efficiency of these machines is also highlighted in their energy consumption; electric models typically use less energy than their gas counterparts.

Users appreciate the quieter operation of electric pressure washers, making them suitable for residential areas without causing disturbances. This feature, along with low emissions and eco-friendliness, aligns with growing environmental concerns.

In conclusion, the Briggs & Stratton Electric Pressure Washer stands as a testament to efficient and effective cleaning solutions. With its powerful motor, adjustable nozzles, lightweight design, and environmental advantages, it caters to consumers seeking an efficient machine for their cleaning needs. Whether cleaning vehicles, outdoor furniture, or various surfaces around the home, this pressure washer delivers reliable performance every time.