7.Connect generator power supply conductors from the generator’s control panel to transfer switch terminals marked “GENERATOR”. Each conductor should pass through hole of current transformer before making connection.

8.Connect generator Neutral from the generator control panel to the transfer switch “NEUTRAL” terminal.

9.Connect generator Ground from the control panel to the transfer switch “GND” terminal.

10.Plug in current transformer leads into “CT1” and “CT2” terminals on control module.

NOTE: Assure generator equipment grounding conductor is connected per applicable federal, state and local codes, standards and regulations.

11.Connect generator “UTILITY 240 VAC” terminals to transfer switch “UTILITY 240 VAC” terminals. Use minimum #14 AWG conductors.

12.Tighten all wire connections/fasteners to proper torque. See inside transfer switch enclosure for proper torque values.

Supervisory Control Wiring

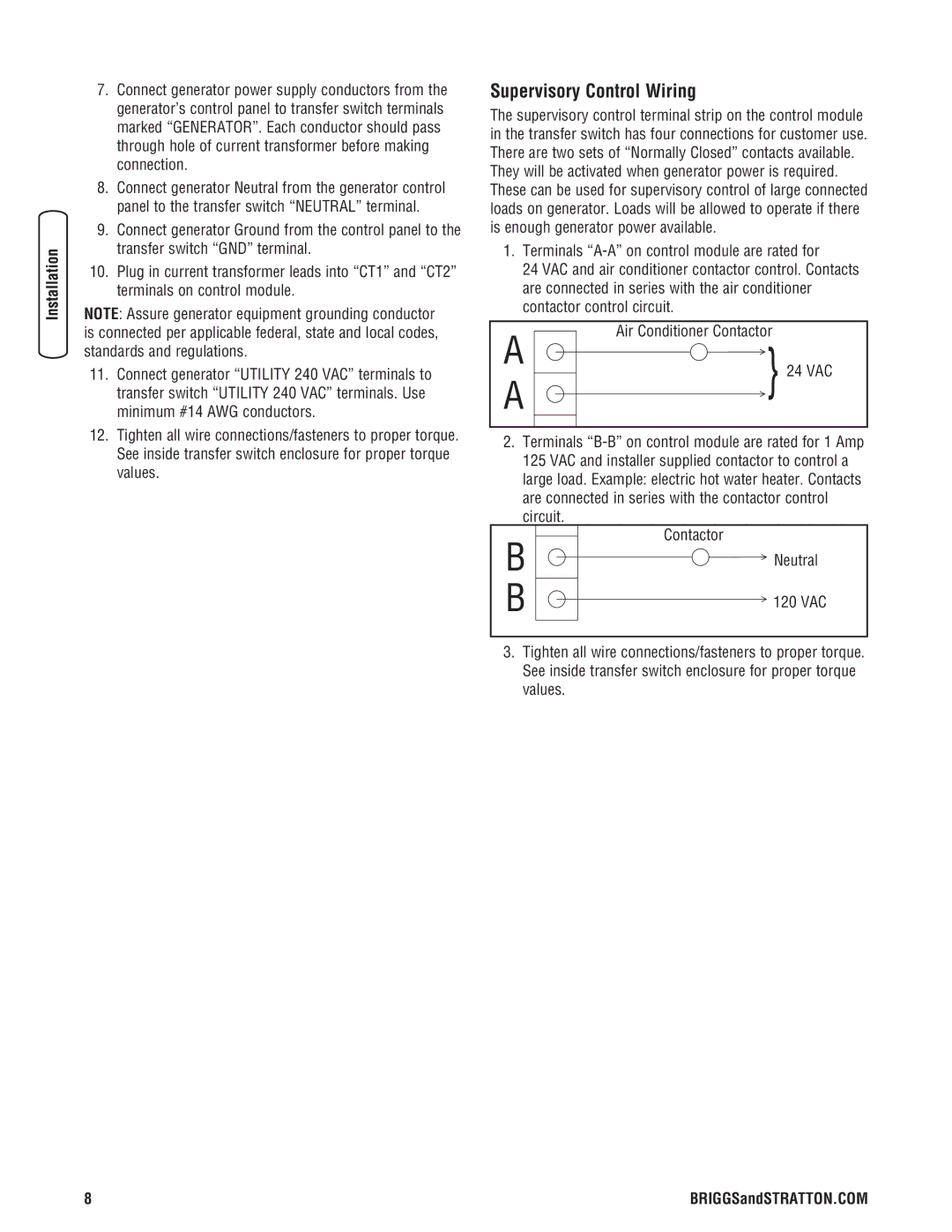

The supervisory control terminal strip on the control module in the transfer switch has four connections for customer use. There are two sets of “Normally Closed” contacts available.

They will be activated when generator power is required. These can be used for supervisory control of large connected loads on generator. Loads will be allowed to operate if there is enough generator power available.

1.Terminals

24 VAC and air conditioner contactor control. Contacts are connected in series with the air conditioner contactor control circuit.

A | Air Conditioner Contactor | |

24 VAC | ||

A | ||

|

2. Terminals

B | Contactor | |

Neutral | ||

| ||

B | 120 VAC |

3.Tighten all wire connections/fasteners to proper torque. See inside transfer switch enclosure for proper torque values.