GAS LEAK TESTING:

1.Create a mixture of 50% water and 50% liquid dishwashing soap.

2.To turn on the fuel supply, turn the cylinder valve knob one turn counterclockwise.

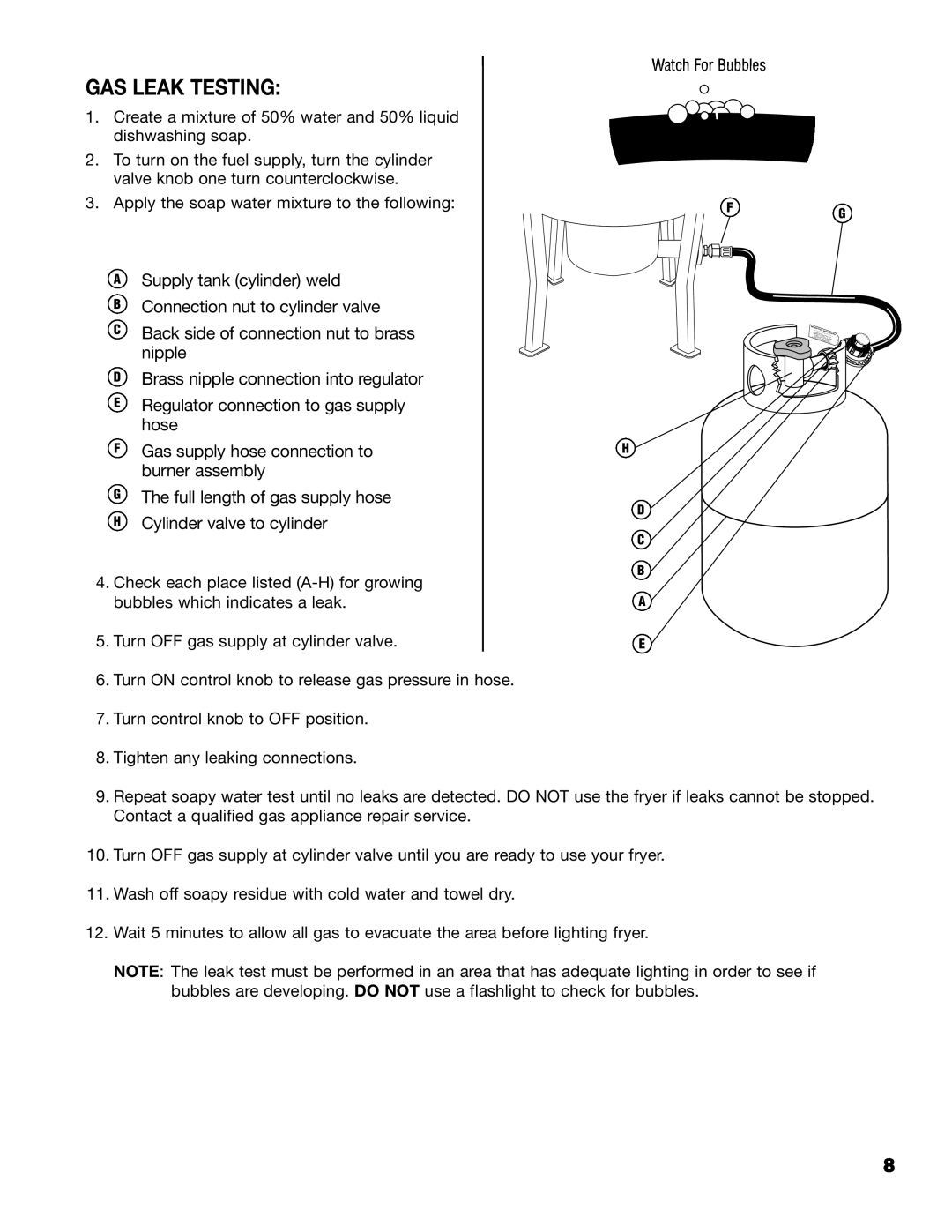

3.Apply the soap water mixture to the following:

A Supply tank (cylinder) weld

BConnection nut to cylinder valve

CBack side of connection nut to brass

nipple

DBrass nipple connection into regulator

ERegulator connection to gas supply hose

FGas supply hose connection to burner assembly

GThe full length of gas supply hose

HCylinder valve to cylinder

4.Check each place listed

5.Turn OFF gas supply at cylinder valve.

6.Turn ON control knob to release gas pressure in hose.

7.Turn control knob to OFF position.

8.Tighten any leaking connections.

Watch For Bubbles

FG

IMPORTANT

FLUATCSMTUOINARENGNNTAKVRDG.AOJUALULVSSSEEVOTAOTMSAFEGUNLHNEVAINSELNT.DRPFOO.EOGDRFAFSARD

NLY.

H

D

C

B

A

E

9.Repeat soapy water test until no leaks are detected. DO NOT use the fryer if leaks cannot be stopped. Contact a qualified gas appliance repair service.

10.Turn OFF gas supply at cylinder valve until you are ready to use your fryer.

11.Wash off soapy residue with cold water and towel dry.

12.Wait 5 minutes to allow all gas to evacuate the area before lighting fryer.

NOTE: The leak test must be performed in an area that has adequate lighting in order to see if bubbles are developing. DO NOT use a flashlight to check for bubbles.

8