ST-251BH, ST-151BH specifications

The Brinly-Hardy ST-151BH and ST-251BH are top-of-the-line tow-behind spreaders designed specifically for efficiently distributing a range of materials, including fertilizer, seed, and various other lawn care products. Known for their durability and advanced features, these spreaders have become essential tools for both homeowners and professional landscapers alike.One of the main features of the ST-151BH and ST-251BH is their robust construction. Both models are built with corrosion-resistant materials, ensuring longevity even when exposed to harsh outdoor elements. The steel frame provides exceptional strength, while the UV-resistant polyethylene hopper prevents fading and ensures that the spreaders maintain their aesthetic appeal over time.

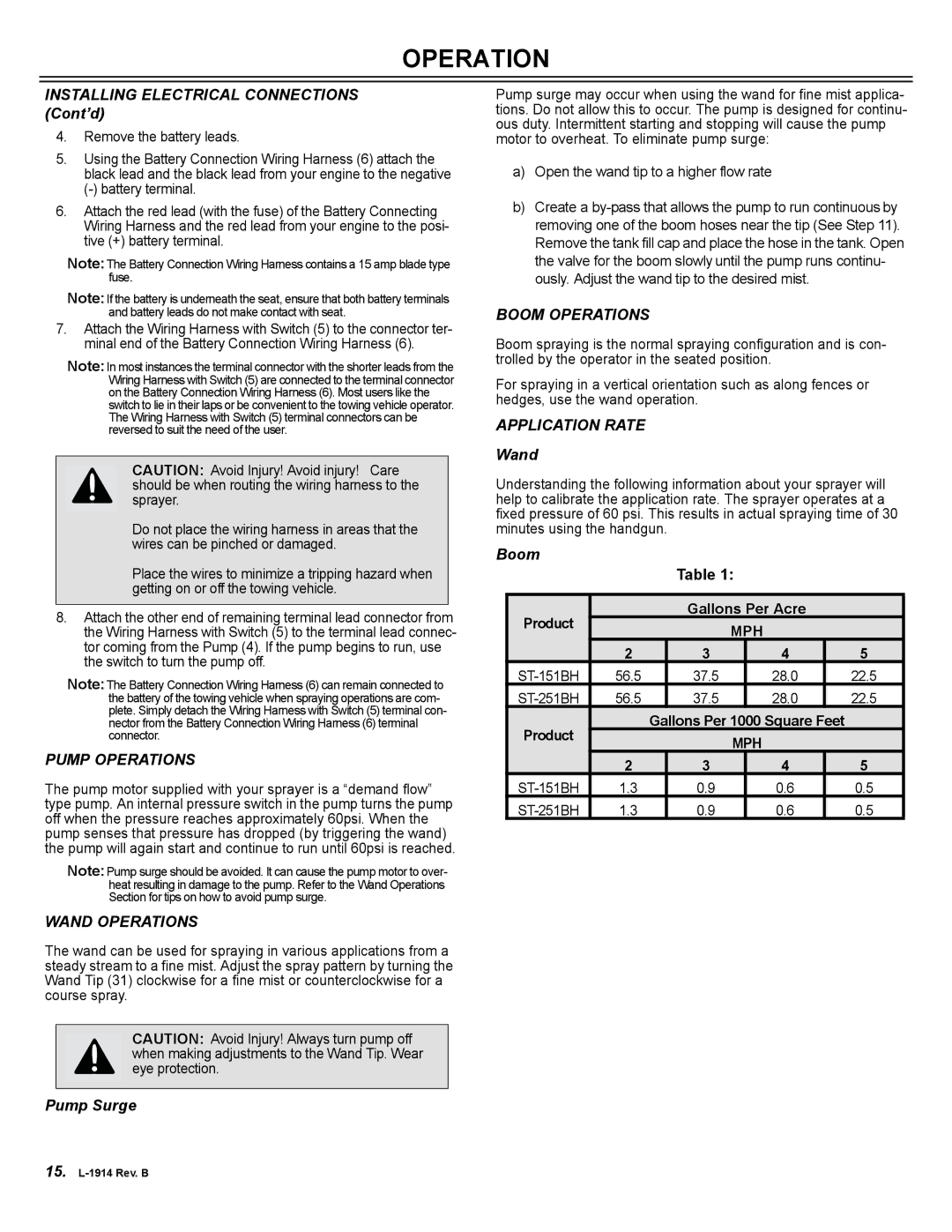

In terms of capacity, the ST-151BH boasts a 150-pound capacity, while the ST-251BH offers an impressive 250-pound capacity. This allows users to cover large areas without frequent refills, making these spreaders ideal for expansive lawns, gardens, and commercial landscapes.

Technologically, the Brinly-Hardy spreaders are equipped with a unique, adjustable flow rate system. This feature enables users to customize the rate at which materials are dispensed, ensuring accurate and even coverage. This precision not only enhances the effectiveness of the application but also minimizes waste, making it both an environmentally friendly and cost-effective solution.

The spreaders also integrate a heavy-duty gear-driven system, which offers reliable and consistent performance, even in challenging terrain. The large, pneumatic tires provide excellent traction, ensuring smooth operation across various surfaces, from gravel paths to grassy lawns.

Furthermore, both models are designed for easy assembly and use. The ergonomic handle provides comfortable control, while the integrated shut-off system allows for quick stops, reducing the chances of unnecessary material loss.

In conclusion, the Brinly-Hardy ST-151BH and ST-251BH represent the perfect blend of quality, efficiency, and innovation. With their durable construction, customizable features, and ease of use, these spreaders are undoubtedly valuable tools for anyone looking to promote healthy growth in their lawn or garden. Whether for personal use or professional landscaping, they deliver performance that meets the highest standards.