BE-1204B-BC BE-1204C-BC BE-1206B-BC

Page

Safety indications and their meanings

Indications

Damage to equipment and surroundings

Environmental requirements

Installation

Sewing

Cleaning

Maintenance and inspection

Injury caution display

W1206Q

W1400Q W1208Q

Before Starting Operation

Protecting data in floppy disks

Procedure of Reading This Manual

Configuration of this manual

Explanation of models

Contents

Functions Command Reference

Changing Data

Embroidering

Operating Procedures

Error code list Troubleshooting

Chapter An Introduction Embroidery Machine

Specifications

BE-1204B-BC BE-1204C-BC BE-1206B-BC

Program Functions

Configuration of Software

Software

Necessary Systems

Relationship among Programs

Help

How to Use the Mouse

Basic Operation of Software

Click

Drag

Double-click

Scroll bar, scroll box, and scroll arrow

Names of Screen Components

Menu

Tool bar

Selection of Menu

List of commands is displayed. Click the required command

BE-1204B-BC BE-1206B-BC

Chapter Preparation of Embroidery Machine

Names of Machine Components

Installation

When using a fork lift

Transportation of Machine

Hook on the eyebolts with each belt to lift up the machine

When using a crane

Installation of Machine

Preparation of Needle Bar Case

Preparation for mounting the table

Mounting of Table

W1227Q

For embroidering with flat hoop/sash frame upper position

Mounting of Cotton Stand

Lubrication to Needle Bar Case

Be sure to ground the personal computer

Terminator

Uninterruptive power supply

Connection of Power Supply

Grounding

Select the language and click Next

Installation of Software

Upper Threading

Preparation for Embroidering

W1234Q

Put a new bobbin in the bobbin case

Replacement of Bobbin

Removing bobbin case

Replacing bobbin

Attaching bobbin case

Attaching needle

Replacing and Selecting Needle

Selecting needle

Removing needle

Tubular square hoop BE-1204B,BE-1206B

Attachment of Embroidery Hoop and Frame

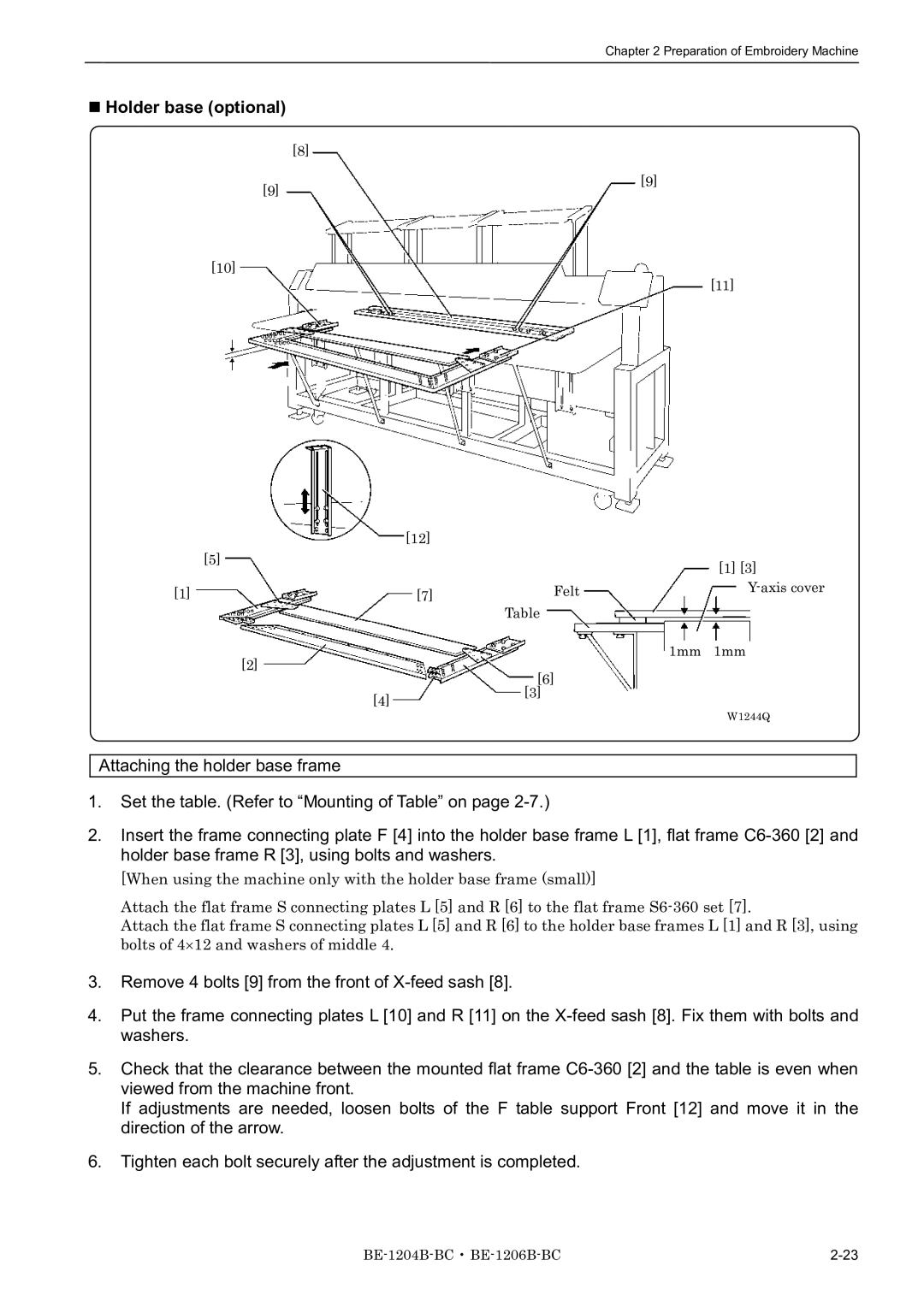

Holder base optional

W1246Q

BE-1204B Sash clips 290 10 units, sash clips 220 6 units

Sash frame optional

Adjustment of Thread Tension

Adjustment of upper thread

Adjustment of tension spring

Lower thread tension

BE-1204B-BC BE-1206B-BC

Chapter Embroidering Procedures

Operation Panel

Functions of Operation Panel

Switch

Switches at Machine Heads

Lamps and switches on the thread tension stand

Flowchart of Preparation for Embroidering

Run the Software

Turn on the Machine Power

Click

Register the Machine Name

Retrieve the Embroidery Data

Click OK

Start Embroidering

BE-1204B-BC BE-1206B-BC

Chapter Selecting and Transferring Embroidery Data

View menu

Functions Command Reference

File menu

Edit menu

Description of Screen

Click OK New directory is added to the window

Creating a Directory

Select New Folder from File menu

Enter a new folder name

Transferring DST and DSB data

Transferring data

If no image appears

Transferring data on a network

Select destination directory. Name copy data

Copy

Select from Menu

Drag Data

Select the destination directory and click Save

Moving Data

Click Yes to delete the selected data

Deleting Data

Deletes embroidery data Click data for selection

Select Delete from Edit menu or click

Recreate an icon

Select All

Renaming Data

Extension

Select Rename from Edit menu or click Enter a new data name

Click Find

Finding Data

Finding Files With Wildcard Characters

Adjusting Screen Display

Image of the selected pattern appears

Reading Data in Floppy Disk

Reading DOS Format Data

Non DOS format data

Select the directory to save and name the file

Converting the Non DOS format data

This function is not available with Windows NT

Viewing Files

Viewing Icon Click

Select data to read and click OK

Select the directory to save the file and name the file

Reading Data in Paper Tape

W0997Q

Settings for Data Reading

Writing Data in DST Format

Viewing Pattern Information

Chapter Editing Embroidery Data

Change menu

BE-1204B-BC BE-1206B-BC

Fit to Window

Opening Embroidery Data

Zoom

Setting Display

Centering

Zoom

Fit to window

Zoom Out

Select Zoom Zoom Out from View menu or click

Range

Needle Penetration

Embroidering Start/End

Trim and pause

Microstitch

Needle Bar and Speed Range

Displays status of the needle bar and speed range

Change of display color

Select a new color on the Color selection screen

W1021Q

Drag the embroidering sequence on the needle bar number

Setting the range

Thread Color

Changing needle bar allocation

Select Status Bar from View menu

Tool bar

Status Bar

Select Tool Bar from View menu

Redo

Repeats the canceled step of Undo

Back to Previous Status

Undo

Editing

Rotate

Select Rotate from View menu or click Select angle

Repeat

Horizontal Flip

Vertical Flip

Point Symmetry

W0716Q W0717Q

Set the vertical and horizontal margin for sewing area

Margin setting with Auto setting selected

Click OK Deleted result is displayed. Click OK

Resize

Delete Stitch

Resizes the image

Move the needle position to the desired position

Insert or Delete Code

Select Insert or delete code from the Edit menu

Select the movement method of needle position

If the lock stitch can be inserted, click Yes

Insert Lock Stitch

Select Start from Change menu

Changing Data

Changing Start

Changes the start position of embroidering

Changing End

Changes the end position of embroidering

Select End from Change menu

Mask

Group

Setting Group for Repetition

Selecting from Menu

Select Group from Change menu

Merge

Pattern is merged

If the position is acceptable, click Yes

Save

Saving Data

Renames and saves the edited data as a new file

Save As

Viewing Pattern Information

Prints data in editing Select Print from File menu or click

Printing Data

BE-1204B-BC BE-1206B-BC

Embroidering

Machine menu

When the Power to the Machine is Off

When the Power to the Machine is On

Configuration menu

Operation menu

Window menu

Settings menu

W1060Q

Select Tool Bar from View menu and put the check mark

Settings before Turning On the Machine

Displaying the Tool Bar

There are two kinds of tool bars as follows

Communication Port

Reset Interface Board

Displaying the Status Bar

Upgrading the Version of Interface Board

Language

Changes display language

Click OK Exit and rerun the software

Reduces the image to 80%

Settings after Turning Power On

Zoom Out

Enlarges the image to 125%

Displays the whole embroidery area

Zoom In Specified Range

Fit to Window

Whole Pattern

Hoop

Hoop position fine adjustment

Adjusts the view position of embroidery hoop

Grid

Designate the adjusting position and click OK

Displays the needle bar and speed range

Setting Needle Bar

Same function

Select Thread Color from View menu and put the check mark

Double-click the thread spool or needle bar number

Changing display colors

Select a new color on the Color selection screen

Drag a thread spool to the desired needle bar number

Click Up to increase range. Click Down to reduce range

Setting Ranges

There are two methods for setting ranges

Changing all ranges

Changes the background color of the data

Grid Setting

Background color

Sets the pitch and the color of grid

Rename the registered machine

Renaming Machine

Viewing Machine Information

Setting Window Display

Detail specification of the machine can be displayed

Detail specification of the embroidery data can be checked

Window is minimized

Minimizing and Aligning Windows

Select Cascade or Tile from Window menu

Minimize Window Size

Arrange Icons

Minimized windows are aligned

Changing window size

Click and select the machine name of the destination

Copying Data to Other Machines

Configuration

Upgrading the Machine Program

Sets the environment of data reading and display

Patterns are sewn by one needle

Setting the Machine

Select Needle Default value from Settings menu

Needle Bar

Embroiders patterns at the specified speed range

Resetting temporary stop of all the needle bars

Same Speed Range

Pause

Speed Range

Head Operation Suspend

Sets the machine head for rest

Gray cross appears and shows the hoop feed position

Hoop Feed Position

Type of specified embroidery hoop changes the display

Embroidery Area

Embroidery Hoop

Sets the embroidery area

Following shows the screen example with the frame selected

Select Embroidery Hoop and the type from Settings menu

Thread Trimming

Thread Breakage Sensor

Adjust the sensor sensitivity

Automatic Step Back

Automatic Hoop Feed

Sets automatic hoop feed for a thread breakage

End of embroidery

Select End of embroidery from Settings menu

Items and descriptions are as follows

Select Mending from Settings menu

Mending

Sets the details of mending

When setting is complete, click OK

Adjust

Click OK when the items are set

Adjustment value of the needle is set

Activate escape with pause

Select Driving shaft from Settings menu and check it

When the item selection is completed, click OK

Driving shaft

Short stitch speed reduction

Reduces speed when stitching in a designated pitch

Thin / Thick Material

Adjusts the timing of needle drop and hoop movement

Trace with needle No

Area Trace

Default Settings

Resets changes of the machine setting to the default

Items for setting and initialization are as follows

Shows the setting contents and defaults

Show Setting

After checking, check OK

Select Show Setting from Settings menu

Load Setting

Load the setting

Select the folder and click Open

Save Setting

Saves the edit settings

Select the registration folder and put a file name

Load the optional hoop displayed in Hoop

Load Hoop

SPIDERNETFRAME19B.ehp

Tubular round frame TUBULARROUND07.ehp TUBULARROUND09.ehp

Select Load hoop from Settings menu

Embroidering

Pause

Moving the Home Position

Step-forward/Step-back

Select step-forward/back distance or timing

Canceling step-forward/step-back

Steps forward/back the stitches actually

Stepping Forward/Back

Resuming Embroidering

Moving Embroidery Position

Centering Pattern

Saving Data

Test

Running Other Programs

Embroidering

Operation of Machine

Pressing starts embroidering

Operating Procedures

Power Source

Preparation for Embroidering

Emergency Stop of the Machine

Resetting Emergency Stop

Machine Stop

Stopping the Machine

Permission for Hoop Movement

Remedies

Measures against Thread Breakage

Mending

Case of Mending usage

Manual operation of the mending

Jog Embroidering

Hoop Feed Position

Area Check

External Tracing

Automatic Hoop Movement in Area

Hoop Movement to Start Position

Jog Switches

Pressing resets the inching mode Press restarts embroidering

Inching Mode during Embroidering Forcible Hoop Movement

Chapter Creating Production Report

Items to be displayed Sets the display item. →

W1177Q

Click OK Specify the period to read

Displaying Report

Following information is indicated under the Reason column

Display Example of Details

Display in graph

Display in text

Display Example of Thread breakage Information in Pattern

Displays thread breakage information for each pattern

Click tab to display other patterns with the graph

Display Example of Output Information

Details of reason for stoppage

Display Example of Total Output Information

W1186Q

General

Setting Display Items

Main items to be displayed Displays each event and the time

Details

Thread Breakage Information on Needle Bar

Thread Breakage Information in Pattern

Main items to be displayed

Items to be displayed

Output Information

Total Output Information

Recess Time Setting

Save As CSV

Printing method is set as required

Setup

Printing Production Report

Print

Copying Report Data

Maintenance

Cleaning and Lubrication of Rotary Hook

Cleaning

Cleaning of Needle Plate

Oiling

Head

Supply oil to the following places at regular intervals

Lubricate the lower shaft bush F every 3 months

Lower shaft

Greasing

Cam grooves

Supply grease to the following places at regular intervals

Attach the head cover front L

Grease all the cam grooves of the work clamp cam

Lower gear

Attach the bed cover B

Attach the table cover L

Attach the head cover R

Needle bar flip-up mechanism

Feed Guide Section

Adjustment

Adjusting Needle Bar Height

10-3

When using the bottom dead center gauge

10-5

Attachment and Adjustment of Rotary Hook

Fully tighten the screw

Adjustment of Presser Foot Height

Thread Wiper Adjustment

Adjustment 10-10

Error code list

Press Or turn on the F/B switch on the head to either

Needle bar No. of the destination is out Press

CPU

Or turn on the F/B switch on the head to either side

PCB CPU

11-7

Error code list 11-8

Troubleshooting

Mechanical Section

Once again

Electrical Section

12-5

12-6

12-7

Trouble Check Point

Personal Computer Section

Chapter Connection and Installation Optional Equipment

Attaching Bobbin Winder

Winding lower thread

Connection and Installation of Optional Equipment 13-4

Page

Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan. Phone