System Functions And Sequence Of Operation

The outdoor unit control system has special functions. The following is an overview of the

Cooling Operation

187A and 180A (containing circuit board HK38EA015 or newer) models utilize either a

NOTE: On 187A models, if unit has not operated within the past

12hrs, or following a unit

NOTE: With

NOTE: When

NOTE: Outdoor fan motor will continue to operate for one minute after compressor shuts off, when outdoor ambient is greater than or equal to 100_F (37.78_C). This reduces pressure differential for easier starting on the next cycle.

Communication and Status Function Lights

For Evolution Control Only, Green communications (COMM) Light

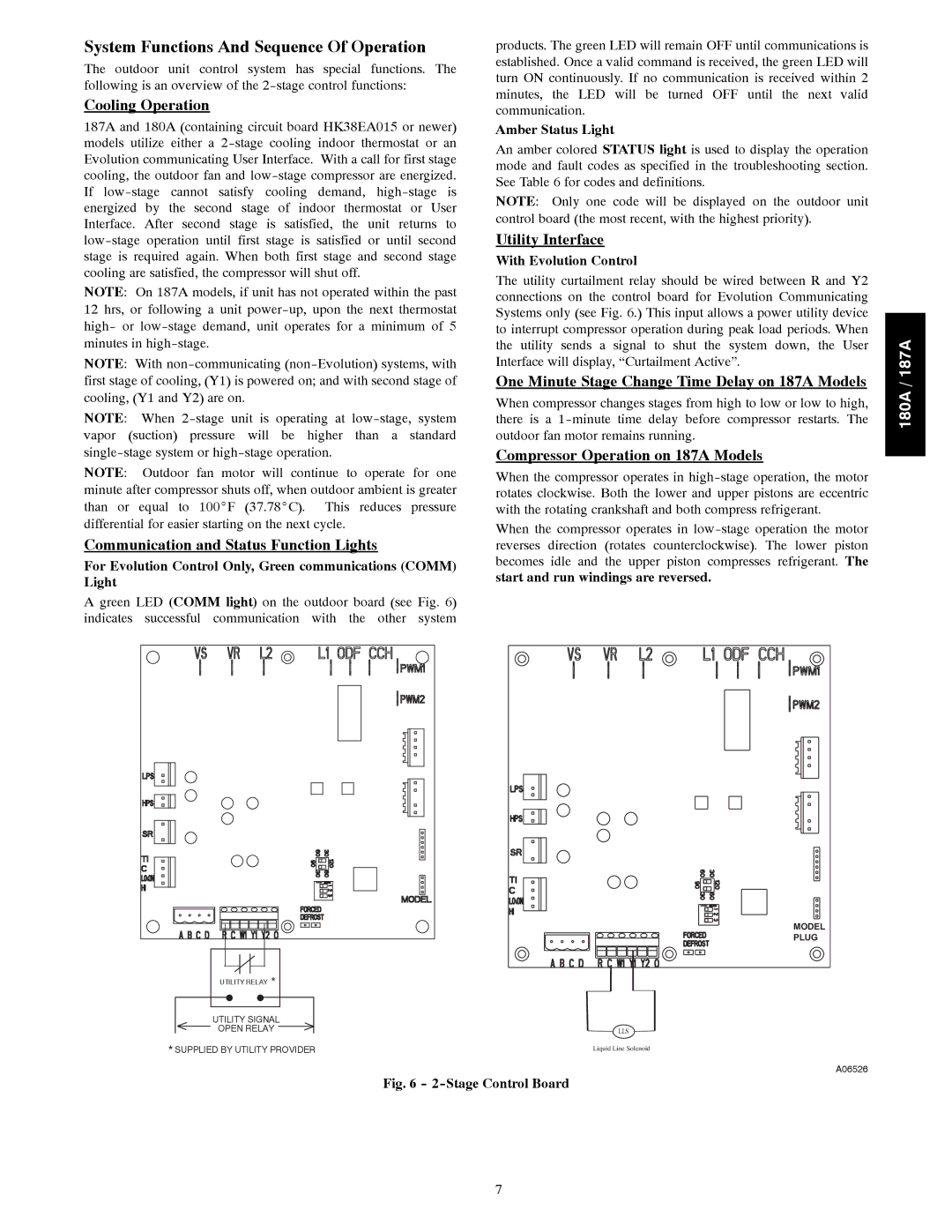

A green LED (COMM light) on the outdoor board (see Fig. 6) indicates successful communication with the other system

products. The green LED will remain OFF until communications is established. Once a valid command is received, the green LED will turn ON continuously. If no communication is received within 2 minutes, the LED will be turned OFF until the next valid communication.

Amber Status Light

An amber colored STATUS light is used to display the operation mode and fault codes as specified in the troubleshooting section. See Table 6 for codes and definitions.

NOTE: Only one code will be displayed on the outdoor unit control board (the most recent, with the highest priority).

Utility Interface

With Evolution Control

The utility curtailment relay should be wired between R and Y2 connections on the control board for Evolution Communicating Systems only (see Fig. 6.) This input allows a power utility device to interrupt compressor operation during peak load periods. When the utility sends a signal to shut the system down, the User Interface will display, “Curtailment Active”.

One Minute Stage Change Time Delay on 187A Models

When compressor changes stages from high to low or low to high, there is a

Compressor Operation on 187A Models

When the compressor operates in

When the compressor operates in

180A / 187A

UTILITY RELAY * |

UTILITY SIGNAL

OPEN RELAY ![]()

MODEL |

PLUG |

LLS |

* SUPPLIED BY UTILITY PROVIDER | Liquid Line Solenoid |

A06526

Fig. 6 - 2-Stage Control Board

7