Charging In Cooling Mode - 280ANV024/036

See user interface set in Charging Mode

Heating Check Chart - 280ANV024/036

| 400 | | | For use in Heating Charging Mode only | | | 2757 | |

| | | | | | | | | |

| 350 | | | | 80ºFID | (27ºC) | | | | 2413 | |

| | | Vapor Service | | 70ºFID(21ºC) | | | | |

(psig) | 300 | | Valve Pressure | | | | | | 2068 | (KPa) |

| | | | | | | | (16ºC) | |

| | | | | | | ID | |

250 | | | | | | | 60ºF | | 1724 |

Pressure | | | | | | | | | Pressure |

200 | | | | | | | | | 1380 |

Refrigerant | 150 | | | | | | | | | 1034 | Refrigerant |

100 | | | | | | | | | 690 |

| Suction Pressure | | | | | | | |

| | | | | | | | | |

| 50 | | | | | | | | | 345 | |

| 0 | 0 | 10 | 20 | | 30 | 40 | 50 | 60 | 0 | |

| | | | |

| (-18ºC) | (-12ºC) | (-7ºC) | | (-10ºC) | (4ºC) | (10ºC) | (16ºC) | | |

Outdoor Ambient Temperature ºF (ºC)

A12045

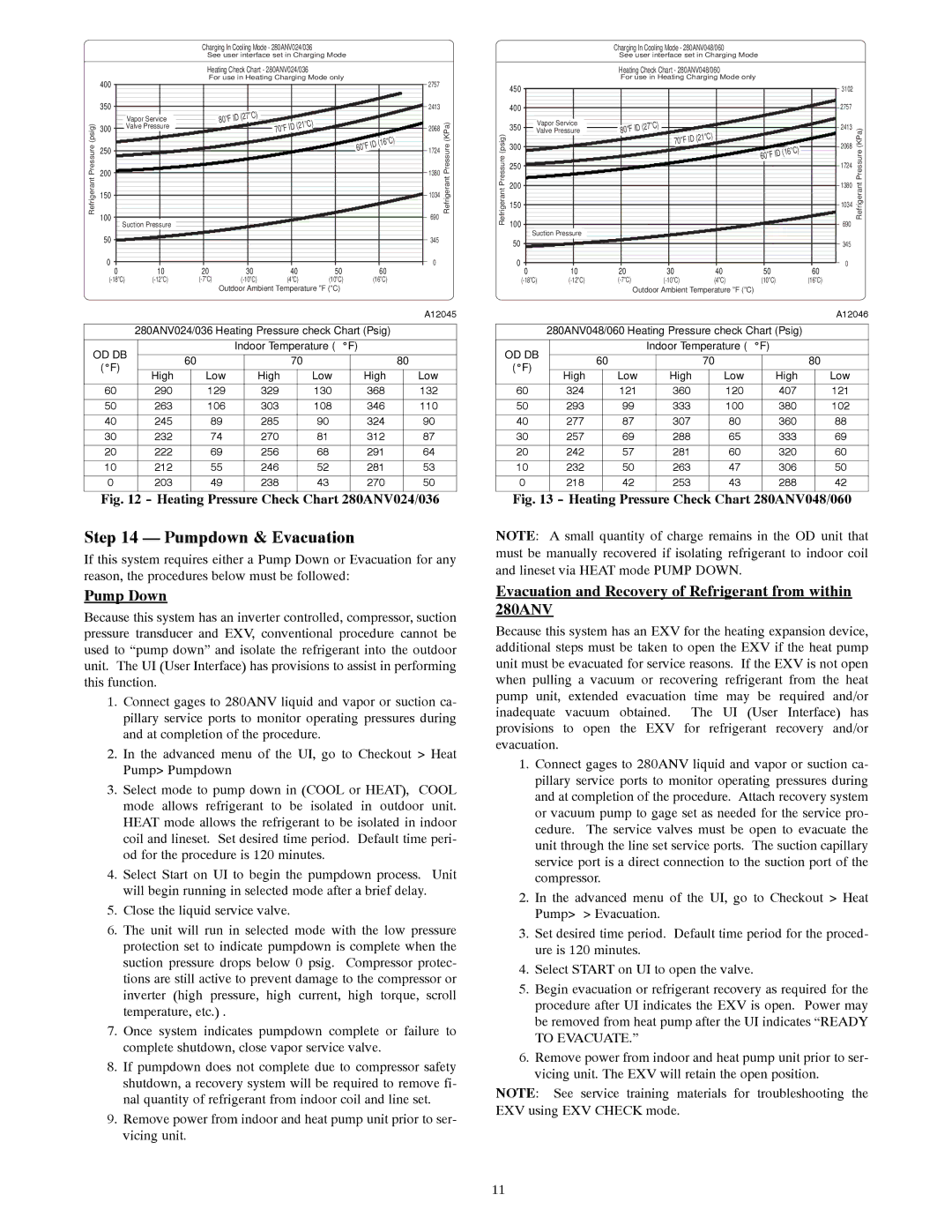

280ANV024/036 Heating Pressure check Chart (Psig)

| OD DB | | | Indoor Temperature (_F) | | |

| | | | | | |

| | 60 | | 70 | | 80 |

| (_F) | | | |

| | | | | | |

| High | Low | High | Low | High | Low |

| |

| 60 | 290 | 129 | 329 | 130 | 368 | 132 |

| 50 | 263 | 106 | 303 | 108 | 346 | 110 |

| 40 | 245 | 89 | 285 | 90 | 324 | 90 |

| 30 | 232 | 74 | 270 | 81 | 312 | 87 |

| | | | | | | |

| 20 | 222 | 69 | 256 | 68 | 291 | 64 |

| | | | | | | |

| 10 | 212 | 55 | 246 | 52 | 281 | 53 |

| | | | | | | |

| 0 | 203 | 49 | 238 | 43 | 270 | 50 |

Fig. 12 - Heating Pressure Check Chart 280ANV024/036

Step 14 — Pumpdown & Evacuation

If this system requires either a Pump Down or Evacuation for any reason, the procedures below must be followed:

Pump Down

Because this system has an inverter controlled, compressor, suction pressure transducer and EXV, conventional procedure cannot be used to “pump down” and isolate the refrigerant into the outdoor unit. The UI (User Interface) has provisions to assist in performing this function.

1.Connect gages to 280ANV liquid and vapor or suction ca- pillary service ports to monitor operating pressures during and at completion of the procedure.

2.In the advanced menu of the UI, go to Checkout > Heat Pump> Pumpdown

3.Select mode to pump down in (COOL or HEAT), COOL mode allows refrigerant to be isolated in outdoor unit. HEAT mode allows the refrigerant to be isolated in indoor coil and lineset. Set desired time period. Default time peri- od for the procedure is 120 minutes.

4.Select Start on UI to begin the pumpdown process. Unit will begin running in selected mode after a brief delay.

5.Close the liquid service valve.

6.The unit will run in selected mode with the low pressure protection set to indicate pumpdown is complete when the suction pressure drops below 0 psig. Compressor protec- tions are still active to prevent damage to the compressor or inverter (high pressure, high current, high torque, scroll temperature, etc.) .

7.Once system indicates pumpdown complete or failure to complete shutdown, close vapor service valve.

8.If pumpdown does not complete due to compressor safety shutdown, a recovery system will be required to remove fi- nal quantity of refrigerant from indoor coil and line set.

9.Remove power from indoor and heat pump unit prior to ser- vicing unit.

Charging In Cooling Mode - 280ANV048/060

See user interface set in Charging Mode

Heating Check Chart - 280ANV048/060

For use in Heating Charging Mode only

| 450 | | | | | | | | | 3102 | |

| 400 | | | | | | | | | 2757 | |

| 350 | Vapor Service | 80ºF | ID(27ºC) | | | | | 2413 | |

| Valve Pressure | | | | | |

| | 70ºFID(21ºC) | | | | | |

Refrigerant Pressure (psig) | 300 | | | | | ID(16ºC) | | 2068 | Refrigerant Pressure (KPa) |

| | | | | 60ºF | |

| | | | | | | |

250 | | | | | | | | 1724 |

| | | | | | | |

200 | | | | | | | | | 1380 |

150 | | | | | | | | | 1034 |

100 | Suction Pressure | | | | | | | 690 |

| | | | | | | |

| | | | | | | | | |

| 50 | | | | | | | | | 345 | |

| 0 | 0 | 10 | 20 | 30 | 40 | 50 | | 60 | 0 | |

| | (-18ºC) | (-12ºC) | (-7ºC) | (-10ºC) | (4ºC) | (10ºC) | (16ºC) | | |

Outdoor Ambient Temperature ºF (ºC)

A12046

280ANV048/060 Heating Pressure check Chart (Psig)

| OD DB | | | Indoor Temperature (_F) | | |

| | | | | | |

| | 60 | | 70 | | 80 |

| (_F) | | | |

| | | | | | |

| High | Low | High | Low | High | Low |

| |

| 60 | 324 | 121 | 360 | 120 | 407 | 121 |

| 50 | 293 | 99 | 333 | 100 | 380 | 102 |

| 40 | 277 | 87 | 307 | 80 | 360 | 88 |

| 30 | 257 | 69 | 288 | 65 | 333 | 69 |

| | | | | | | |

| 20 | 242 | 57 | 281 | 60 | 320 | 60 |

| | | | | | | |

| 10 | 232 | 50 | 263 | 47 | 306 | 50 |

| | | | | | | |

| 0 | 218 | 42 | 253 | 43 | 288 | 42 |

Fig. 13 - Heating Pressure Check Chart 280ANV048/060

NOTE: A small quantity of charge remains in the OD unit that must be manually recovered if isolating refrigerant to indoor coil and lineset via HEAT mode PUMP DOWN.

Evacuation and Recovery of Refrigerant from within 280ANV

Because this system has an EXV for the heating expansion device, additional steps must be taken to open the EXV if the heat pump unit must be evacuated for service reasons. If the EXV is not open when pulling a vacuum or recovering refrigerant from the heat pump unit, extended evacuation time may be required and/or inadequate vacuum obtained. The UI (User Interface) has provisions to open the EXV for refrigerant recovery and/or evacuation.

1.Connect gages to 280ANV liquid and vapor or suction ca- pillary service ports to monitor operating pressures during and at completion of the procedure. Attach recovery system or vacuum pump to gage set as needed for the service pro- cedure. The service valves must be open to evacuate the unit through the line set service ports. The suction capillary service port is a direct connection to the suction port of the compressor.

2.In the advanced menu of the UI, go to Checkout > Heat Pump> > Evacuation.

3.Set desired time period. Default time period for the proced- ure is 120 minutes.

4.Select START on UI to open the valve.

5.Begin evacuation or refrigerant recovery as required for the procedure after UI indicates the EXV is open. Power may be removed from heat pump after the UI indicates “READY TO EVACUATE.”

6.Remove power from indoor and heat pump unit prior to ser- vicing unit. The EXV will retain the open position.

NOTE: See service training materials for troubleshooting the EXV using EXV CHECK mode.