Crankcase Heater Operation

This unit has an internal crankcase heater that will be energized during the off cycle and is intelligently demanded by the system to prevent the compressor from being the coldest part of the system thus enhancing the reliability. The crankcase heater will function as needed any time the outdoor unit is powered. The indoor unit and UI do not need to be installed for the crankcase heater to operate properly.

NOTE: Contactor may close intermittently without the unit starting. This is done to determine whether the control needs to energize the crankcase heater. Closing the contactor powers the inverter and allows the system to check compressor temperature.

Outdoor Fan Motor Operation

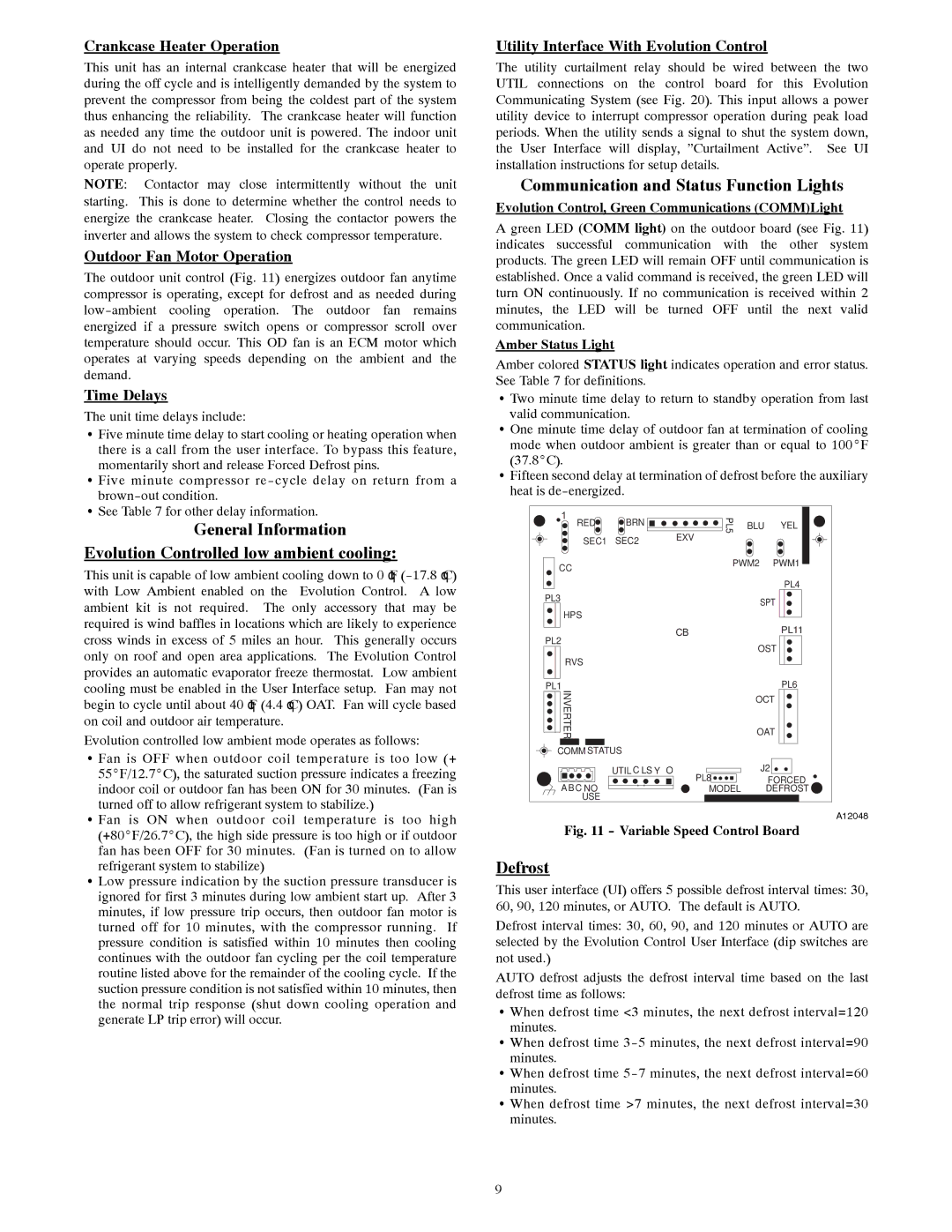

The outdoor unit control (Fig. 11) energizes outdoor fan anytime compressor is operating, except for defrost and as needed during low-ambient cooling operation. The outdoor fan remains energized if a pressure switch opens or compressor scroll over temperature should occur. This OD fan is an ECM motor which operates at varying speeds depending on the ambient and the demand.

Time Delays

The unit time delays include:

SFive minute time delay to start cooling or heating operation when

there is a call from the user interface. To bypass this feature, momentarily short and release Forced Defrost pins.

S Five minute compressor re-cycle delay on return from a brown-out condition.

SSee Table 7 for other delay information.

General Information

Evolution Controlled low ambient cooling:

This unit is capable of low ambient cooling down to 0°F (-17.8°C) with Low Ambient enabled on the Evolution Control. A low ambient kit is not required. The only accessory that may be required is wind baffles in locations which are likely to experience cross winds in excess of 5 miles an hour. This generally occurs only on roof and open area applications. The Evolution Control provides an automatic evaporator freeze thermostat. Low ambient cooling must be enabled in the User Interface setup. Fan may not begin to cycle until about 40°F (4.4°C) OAT. Fan will cycle based on coil and outdoor air temperature.

Evolution controlled low ambient mode operates as follows:

S Fan is OFF when outdoor coil temperature is too low (+ 55_F/12.7_C), the saturated suction pressure indicates a freezing indoor coil or outdoor fan has been ON for 30 minutes. (Fan is turned off to allow refrigerant system to stabilize.)

S Fan is ON when outdoor coil temperature is too high (+80_F/26.7_C), the high side pressure is too high or if outdoor fan has been OFF for 30 minutes. (Fan is turned on to allow refrigerant system to stabilize)

SLow pressure indication by the suction pressure transducer is ignored for first 3 minutes during low ambient start up. After 3 minutes, if low pressure trip occurs, then outdoor fan motor is turned off for 10 minutes, with the compressor running. If pressure condition is satisfied within 10 minutes then cooling continues with the outdoor fan cycling per the coil temperature routine listed above for the remainder of the cooling cycle. If the suction pressure condition is not satisfied within 10 minutes, then the normal trip response (shut down cooling operation and generate LP trip error) will occur.

Utility Interface With Evolution Control

The utility curtailment relay should be wired between the two UTIL connections on the control board for this Evolution Communicating System (see Fig. 20). This input allows a power utility device to interrupt compressor operation during peak load periods. When the utility sends a signal to shut the system down, the User Interface will display, ”Curtailment Active”. See UI installation instructions for setup details.

Communication and Status Function Lights

Evolution Control, Green Communications (COMM)Light

A green LED (COMM light) on the outdoor board (see Fig. 11) indicates successful communication with the other system products. The green LED will remain OFF until communication is established. Once a valid command is received, the green LED will turn ON continuously. If no communication is received within 2 minutes, the LED will be turned OFF until the next valid communication.

Amber Status Light

Amber colored STATUS light indicates operation and error status. See Table 7 for definitions.

S Two minute time delay to return to standby operation from last valid communication.

SOne minute time delay of outdoor fan at termination of cooling

mode when outdoor ambient is greater than or equal to 100_F (37.8_C).

SFifteen second delay at termination of defrost before the auxiliary heat is de-energized.

1 | | BRN | | PL5 | | |

RED | EXV | BLU | YEL |

| SEC1 | SEC2 | | | |

| | | | |

CC | | | | PWM2 | PWM1 |

| | | | | |

| | | | | | PL4 |

PL3 | | | | | SPT |

HPS | | | | |

| | | | | |

PL2 | | | CB | | | PL11 |

| | | | OST |

| | | | |

RVS | | | | | | |

PL1 | | | | | | PL6 |

INVERTER | | | | | OCT |

| | | | OAT |

| | | | |

COMM | STATUS | | | | |

| | UTIL C LS Y | O | | J2 |

A B C NO | | PL8 | MODEL | | FORCED |

| | | DEFROST |

| USE | | | | | |

A12048

Fig. 11 - Variable Speed Control Board

Defrost

This user interface (UI) offers 5 possible defrost interval times: 30, 60, 90, 120 minutes, or AUTO. The default is AUTO.

Defrost interval times: 30, 60, 90, and 120 minutes or AUTO are selected by the Evolution Control User Interface (dip switches are not used.)

AUTO defrost adjusts the defrost interval time based on the last defrost time as follows:

S When defrost time <3 minutes, the next defrost interval=120 minutes.

SWhen defrost time 3-5 minutes, the next defrost interval=90

minutes.

SWhen defrost time 5-7 minutes, the next defrost interval=60 minutes.

S When defrost time >7 minutes, the next defrost interval=30 minutes.