286B / 289B

Field Connections

On

For a communicating system, use the ABCD Evolution connections.

Two Stage Compressor

The two stage compressor contains motor windings that provide

Compressor Internal Relief

The compressor is protected by an internal pressure relief (IPR) which relieves discharge gas into the compressor shell when differential between suction and discharge pressure exceeds

Compressor Control Contactor

The contactor has a 24volt coil. The electronic control board controls the operation of the contactor.

TROUBLESHOOTING

Systems Communication Failure

If communication with the Evolution control is lost with the User Interface, the control will flash the appropriate fault code. (See Table 5.) Check the wiring to the User Interface and the indoor and outdoor units.

Model Plug

Each control board contains a model plug. The correct model plug must be installed for or the system to operate properly. (See Table 4.)

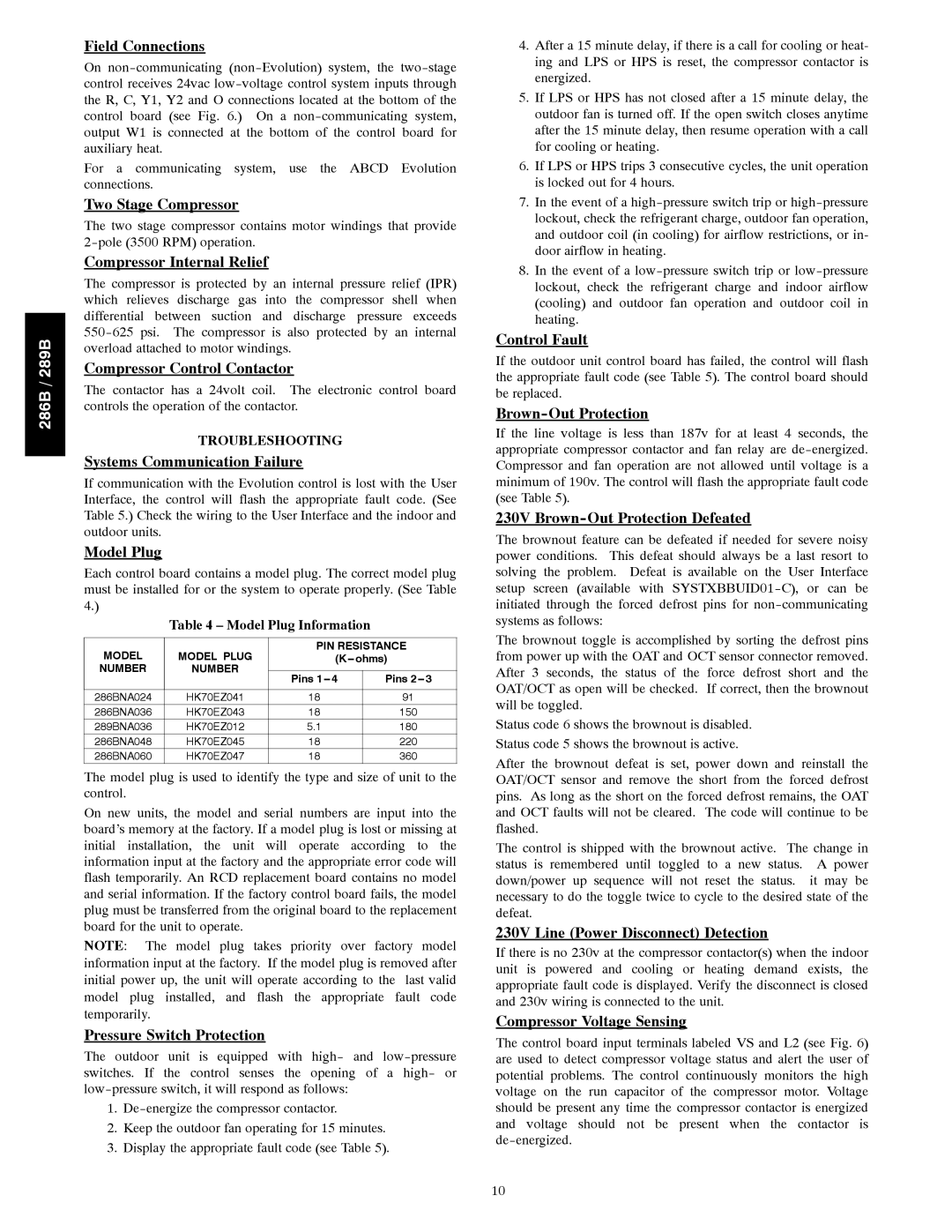

Table 4 – Model Plug Information

MODEL | MODEL PLUG | PIN RESISTANCE | ||

NUMBER | NUMBER |

|

| |

Pins | Pins | |||

|

| |||

|

|

|

| |

286BNA024 | HK70EZ041 | 18 | 91 | |

286BNA036 | HK70EZ043 | 18 | 150 | |

289BNA036 | HK70EZ012 | 5.1 | 180 | |

286BNA048 | HK70EZ045 | 18 | 220 | |

286BNA060 | HK70EZ047 | 18 | 360 | |

The model plug is used to identify the type and size of unit to the control.

On new units, the model and serial numbers are input into the board’s memory at the factory. If a model plug is lost or missing at initial installation, the unit will operate according to the information input at the factory and the appropriate error code will flash temporarily. An RCD replacement board contains no model and serial information. If the factory control board fails, the model plug must be transferred from the original board to the replacement board for the unit to operate.

NOTE: The model plug takes priority over factory model information input at the factory. If the model plug is removed after initial power up, the unit will operate according to the last valid model plug installed, and flash the appropriate fault code temporarily.

Pressure Switch Protection

The outdoor unit is equipped with high- and

1.

2.Keep the outdoor fan operating for 15 minutes.

3.Display the appropriate fault code (see Table 5).

4.After a 15 minute delay, if there is a call for cooling or heat- ing and LPS or HPS is reset, the compressor contactor is energized.

5.If LPS or HPS has not closed after a 15 minute delay, the outdoor fan is turned off. If the open switch closes anytime after the 15 minute delay, then resume operation with a call for cooling or heating.

6.If LPS or HPS trips 3 consecutive cycles, the unit operation is locked out for 4 hours.

7.In the event of a

8.In the event of a

Control Fault

If the outdoor unit control board has failed, the control will flash the appropriate fault code (see Table 5). The control board should be replaced.

Brown-Out Protection

If the line voltage is less than 187v for at least 4 seconds, the appropriate compressor contactor and fan relay are

230V Brown-Out Protection Defeated

The brownout feature can be defeated if needed for severe noisy power conditions. This defeat should always be a last resort to solving the problem. Defeat is available on the User Interface setup screen (available with

The brownout toggle is accomplished by sorting the defrost pins from power up with the OAT and OCT sensor connector removed. After 3 seconds, the status of the force defrost short and the OAT/OCT as open will be checked. If correct, then the brownout will be toggled.

Status code 6 shows the brownout is disabled. Status code 5 shows the brownout is active.

After the brownout defeat is set, power down and reinstall the OAT/OCT sensor and remove the short from the forced defrost pins. As long as the short on the forced defrost remains, the OAT and OCT faults will not be cleared. The code will continue to be flashed.

The control is shipped with the brownout active. The change in status is remembered until toggled to a new status. A power down/power up sequence will not reset the status. it may be necessary to do the toggle twice to cycle to the desired state of the defeat.

230V Line (Power Disconnect) Detection

If there is no 230v at the compressor contactor(s) when the indoor unit is powered and cooling or heating demand exists, the appropriate fault code is displayed. Verify the disconnect is closed and 230v wiring is connected to the unit.

Compressor Voltage Sensing

The control board input terminals labeled VS and L2 (see Fig. 6) are used to detect compressor voltage status and alert the user of potential problems. The control continuously monitors the high voltage on the run capacitor of the compressor motor. Voltage should be present any time the compressor contactor is energized and voltage should not be present when the contactor is

10