Make Electrical Connections

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Do not supply power to unit with compressor terminal box cover removed.

Be sure field wiring complies with local and national fire, safety, and electrical codes, and voltage to system is within limits shown on unit rating plate. Contact local power company for correction of improper voltage. See unit rating plate for recommended circuit protection device.

NOTE: Operation of unit on improper line voltage constitutes abuse and could affect unit reliability. See unit rating plate. Do not install unit in system where voltage may fluctuate above or below permissible limits.

NOTE: Use copper wire only between disconnect switch and unit.

NOTE: Install branch circuit disconnect of adequate size per NEC to handle unit starting current. Locate disconnect within sight from and readily accessible from unit, per Section

Route Ground and Power Wires

Remove access panel to gain access to unit wiring. Extend wires from disconnect through power wiring hole provided and into unit control box.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

The unit cabinet must have an uninterrupted or unbroken ground to minimize personal injury if an electrical fault should occur. The ground may consist of electrical wire or metal conduit when installed in accordance with existing electrical codes.

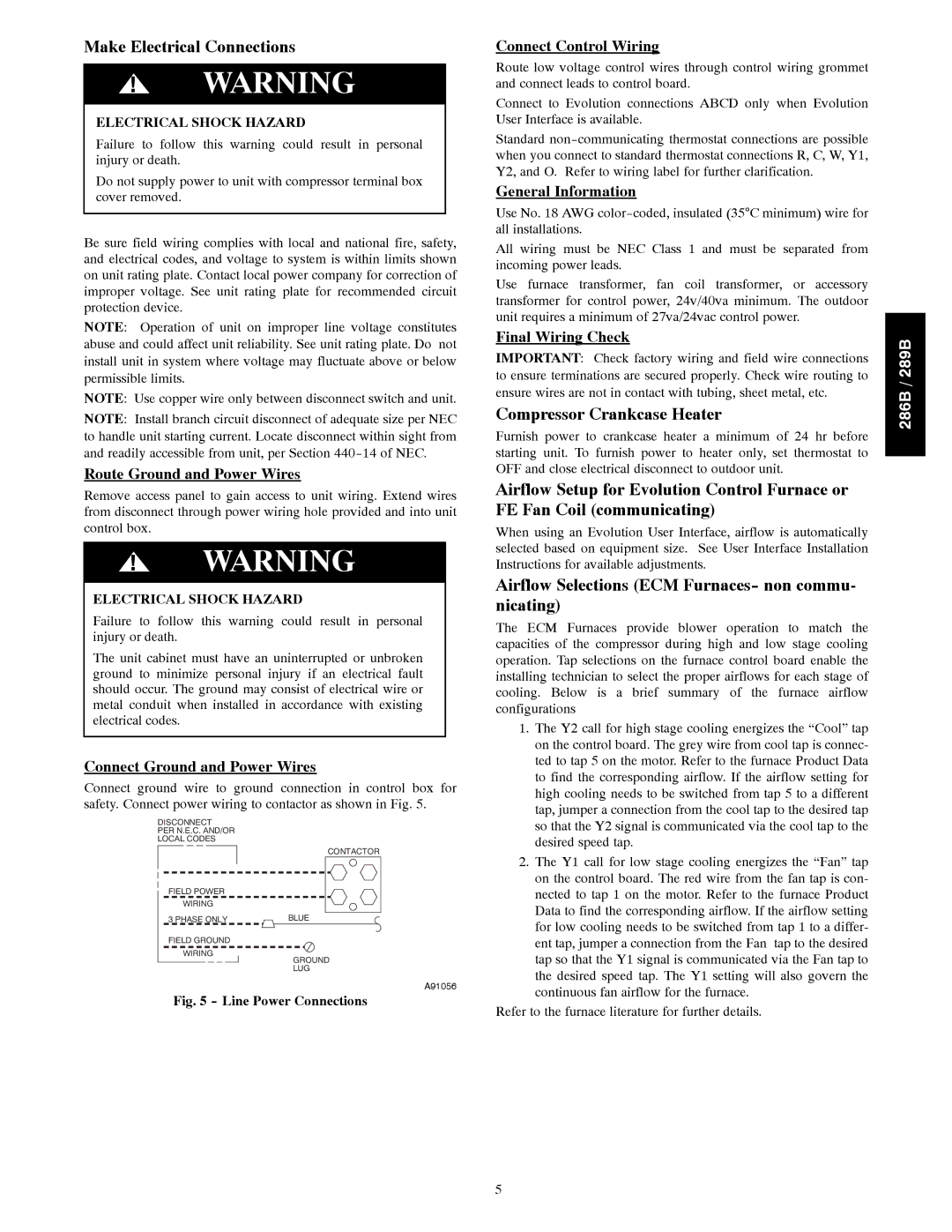

Connect Ground and Power Wires

Connect ground wire to ground connection in control box for safety. Connect power wiring to contactor as shown in Fig. 5.

Connect Control Wiring

Route low voltage control wires through control wiring grommet and connect leads to control board.

Connect to Evolution connections ABCD only when Evolution User Interface is available.

Standard

General Information

Use No. 18 AWG

All wiring must be NEC Class 1 and must be separated from incoming power leads.

Use furnace transformer, fan coil transformer, or accessory transformer for control power, 24v/40va minimum. The outdoor unit requires a minimum of 27va/24vac control power.

Final Wiring Check

IMPORTANT: Check factory wiring and field wire connections to ensure terminations are secured properly. Check wire routing to ensure wires are not in contact with tubing, sheet metal, etc.

Compressor Crankcase Heater

Furnish power to crankcase heater a minimum of 24 hr before starting unit. To furnish power to heater only, set thermostat to OFF and close electrical disconnect to outdoor unit.

Airflow Setup for Evolution Control Furnace or FE Fan Coil (communicating)

When using an Evolution User Interface, airflow is automatically selected based on equipment size. See User Interface Installation Instructions for available adjustments.

Airflow Selections (ECM Furnaces- non commu- nicating)

The ECM Furnaces provide blower operation to match the capacities of the compressor during high and low stage cooling operation. Tap selections on the furnace control board enable the installing technician to select the proper airflows for each stage of cooling. Below is a brief summary of the furnace airflow configurations

1. The Y2 call for high stage cooling energizes the “Cool” tap |

on the control board. The grey wire from cool tap is connec- |

ted to tap 5 on the motor. Refer to the furnace Product Data |

to find the corresponding airflow. If the airflow setting for |

high cooling needs to be switched from tap 5 to a different |

tap, jumper a connection from the cool tap to the desired tap |

286B / 289B

DISCONNECT

PER N.E.C. AND/OR LOCAL CODES

FIELD POWER

WIRING

3 PHASE ONLY

FIELD GROUND

WIRING

CONTACTOR

BLUE

GROUND

LUG

so that the Y2 signal is communicated via the cool tap to the |

desired speed tap. |

2. The Y1 call for low stage cooling energizes the “Fan” tap |

on the control board. The red wire from the fan tap is con- |

nected to tap 1 on the motor. Refer to the furnace Product |

Data to find the corresponding airflow. If the airflow setting |

for low cooling needs to be switched from tap 1 to a differ- |

ent tap, jumper a connection from the Fan tap to the desired |

tap so that the Y1 signal is communicated via the Fan tap to |

the desired speed tap. The Y1 setting will also govern the |

A91056

Fig. 5 - Line Power Connections

continuous fan airflow for the furnace. |

Refer to the furnace literature for further details.

5