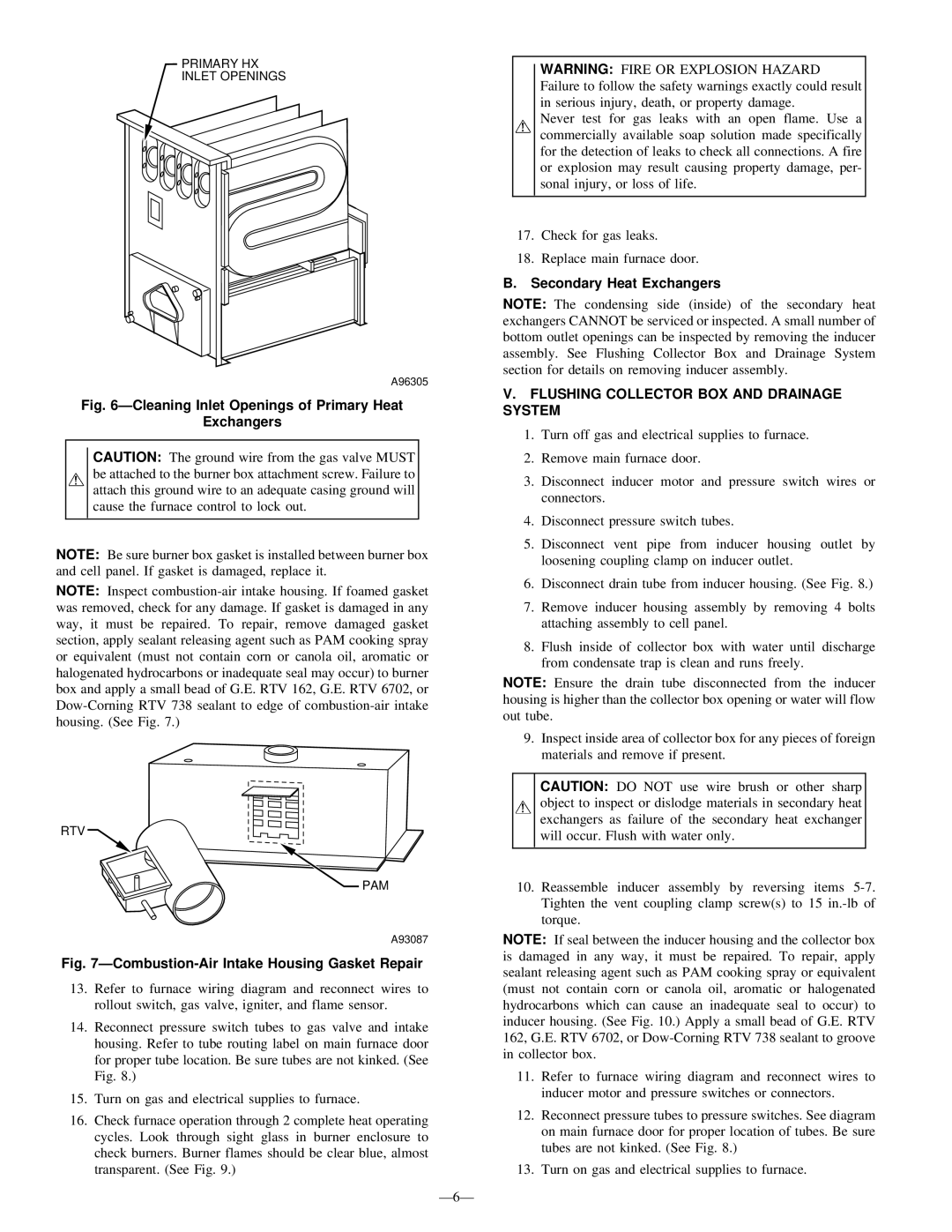

PRIMARY HX

INLET OPENINGS

A96305

Fig. 6—Cleaning Inlet Openings of Primary Heat

Exchangers

CAUTION: The ground wire from the gas valve MUST be attached to the burner box attachment screw. Failure to attach this ground wire to an adequate casing ground will cause the furnace control to lock out.

NOTE: Be sure burner box gasket is installed between burner box and cell panel. If gasket is damaged, replace it.

NOTE: Inspect

RTV![]()

PAM

A93087

Fig. 7—Combustion-Air Intake Housing Gasket Repair

13.Refer to furnace wiring diagram and reconnect wires to rollout switch, gas valve, igniter, and flame sensor.

14.Reconnect pressure switch tubes to gas valve and intake housing. Refer to tube routing label on main furnace door for proper tube location. Be sure tubes are not kinked. (See Fig. 8.)

15.Turn on gas and electrical supplies to furnace.

16.Check furnace operation through 2 complete heat operating cycles. Look through sight glass in burner enclosure to check burners. Burner flames should be clear blue, almost transparent. (See Fig. 9.)

WARNING: FIRE OR EXPLOSION HAZARD Failure to follow the safety warnings exactly could result in serious injury, death, or property damage.

Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the detection of leaks to check all connections. A fire or explosion may result causing property damage, per- sonal injury, or loss of life.

17.Check for gas leaks.

18.Replace main furnace door.

B. Secondary Heat Exchangers

NOTE: The condensing side (inside) of the secondary heat exchangers CANNOT be serviced or inspected. A small number of bottom outlet openings can be inspected by removing the inducer assembly. See Flushing Collector Box and Drainage System section for details on removing inducer assembly.

V.FLUSHING COLLECTOR BOX AND DRAINAGE SYSTEM

1.Turn off gas and electrical supplies to furnace.

2.Remove main furnace door.

3.Disconnect inducer motor and pressure switch wires or connectors.

4.Disconnect pressure switch tubes.

5.Disconnect vent pipe from inducer housing outlet by loosening coupling clamp on inducer outlet.

6.Disconnect drain tube from inducer housing. (See Fig. 8.)

7.Remove inducer housing assembly by removing 4 bolts attaching assembly to cell panel.

8.Flush inside of collector box with water until discharge from condensate trap is clean and runs freely.

NOTE: Ensure the drain tube disconnected from the inducer housing is higher than the collector box opening or water will flow out tube.

9.Inspect inside area of collector box for any pieces of foreign materials and remove if present.

CAUTION: DO NOT use wire brush or other sharp object to inspect or dislodge materials in secondary heat exchangers as failure of the secondary heat exchanger will occur. Flush with water only.

10.Reassemble inducer assembly by reversing items

NOTE: If seal between the inducer housing and the collector box is damaged in any way, it must be repaired. To repair, apply sealant releasing agent such as PAM cooking spray or equivalent (must not contain corn or canola oil, aromatic or halogenated hydrocarbons which can cause an inadequate seal to occur) to inducer housing. (See Fig. 10.) Apply a small bead of G.E. RTV 162, G.E. RTV 6702, or

11.Refer to furnace wiring diagram and reconnect wires to inducer motor and pressure switches or connectors.

12.Reconnect pressure tubes to pressure switches. See diagram on main furnace door for proper location of tubes. Be sure tubes are not kinked. (See Fig. 8.)

13.Turn on gas and electrical supplies to furnace.