363AAP 361AAN specifications

The Bryant 363AAP and 361AAN are standout models in the HVAC industry, offering high efficiency and reliability for residential heating and cooling needs. Designed with advanced technologies, these units are tailored to provide optimal comfort while minimizing energy consumption and operating costs.The Bryant 363AAP is a high-efficiency air conditioning unit that boasts a seasonal energy efficiency ratio (SEER) rating of up to 16. This impressive rating ensures that homeowners can enjoy both a comfortable indoor environment and lower energy bills. Additionally, the unit features a two-stage compressor that allows for better temperature regulation, ensuring consistent cooling and enhanced humidity control.

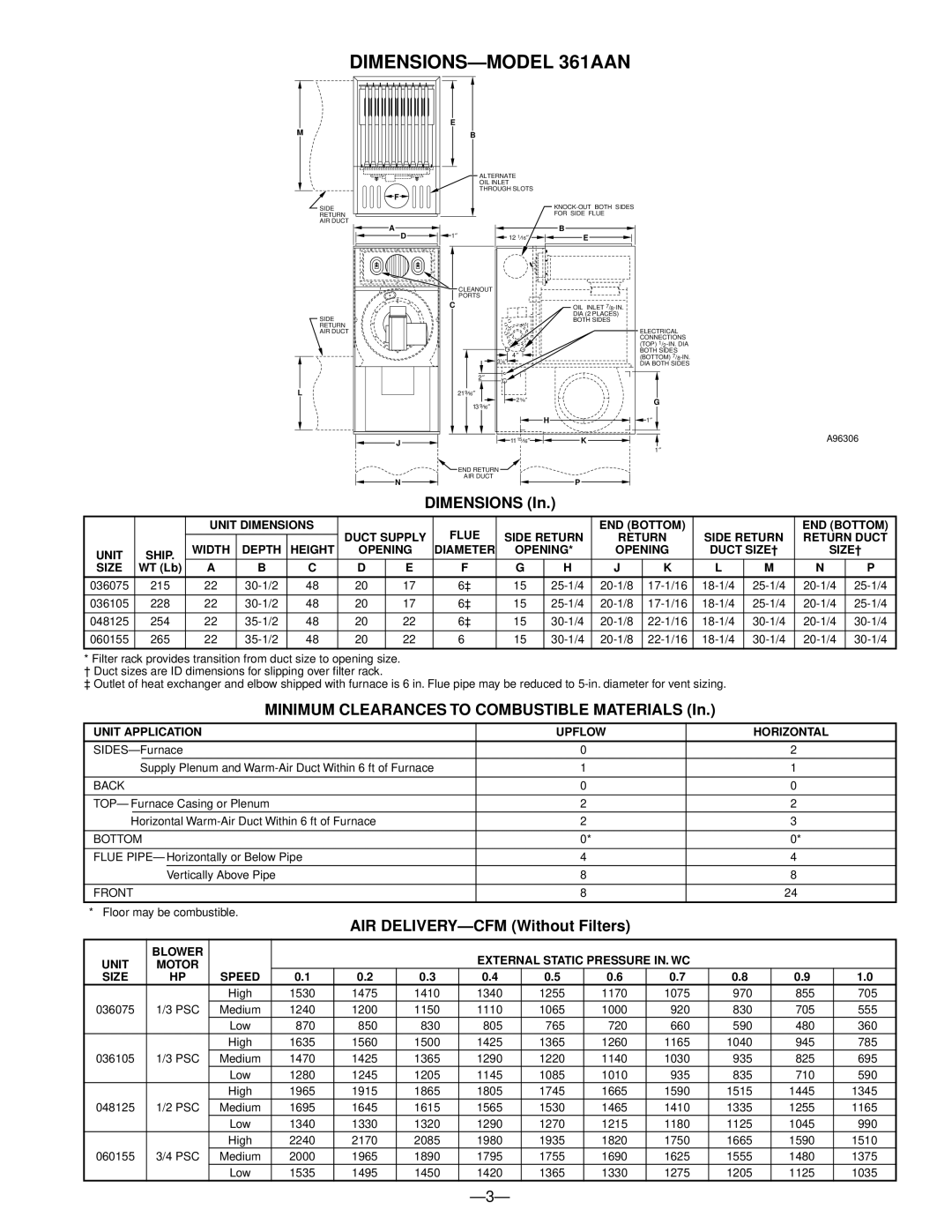

On the other hand, the Bryant 361AAN is a gas furnace that delivers outstanding performance with an Annual Fuel Utilization Efficiency (AFUE) rating of up to 95%. This means that 95% of the fuel consumed is converted into usable heat, providing efficient and cost-effective heating solutions. The 361AAN is equipped with a variable-speed blower motor that optimizes airflow and noise levels, ensuring a quiet and comfortable atmosphere year-round.

Both models incorporate innovative technologies designed to improve indoor air quality and system reliability. The inclusion of Puron refrigerant in the Bryant 363AAP not only aids in enhancing the unit's efficiency but also makes it environmentally friendly by eliminating ozone-depleting substances. Meanwhile, the 361AAN’s compatibility with the Infinity control system allows homeowners to manage their heating and cooling from virtually anywhere, providing added convenience and control through Wi-Fi connectivity.

The robust construction of these models ensures durability and longevity. Featuring galvanized steel cabinets with a powder-coated finish, both units are designed to withstand the elements and resist corrosion. The Bryant 363AAP and 361AAN also come equipped with advanced sound-dampening technology, ensuring quieter operation that will not disturb daily life.

In summary, the Bryant 363AAP and 361AAN stand out for their high efficiency, innovative technologies, and durable construction, making them ideal choices for homeowners seeking reliable heating and cooling solutions. With their commitment to comfort and efficiency, these models set a high standard in the HVAC market.