Remove burner by loosening mounting nuts and turn oil burner slightly counterclockwise to unlock the key hole burner flange. Prevent putting undue strain on burner wiring. (It may be neces- sary to disconnect burner wiring in some cases.)

To reinstall burner, insert on the four burner studs on key hole burner flange and turn it clockwise to lock it and tighten nuts. IMPORTANT: Burner must always be installed in the upright position with ignition control on top.

J. Filters

WARNING: Never operate unit without a filter or with filter access door removed. Failure to adhere to this warning could lead to a hazardous condition which could lead to equipment damage and bodily harm.

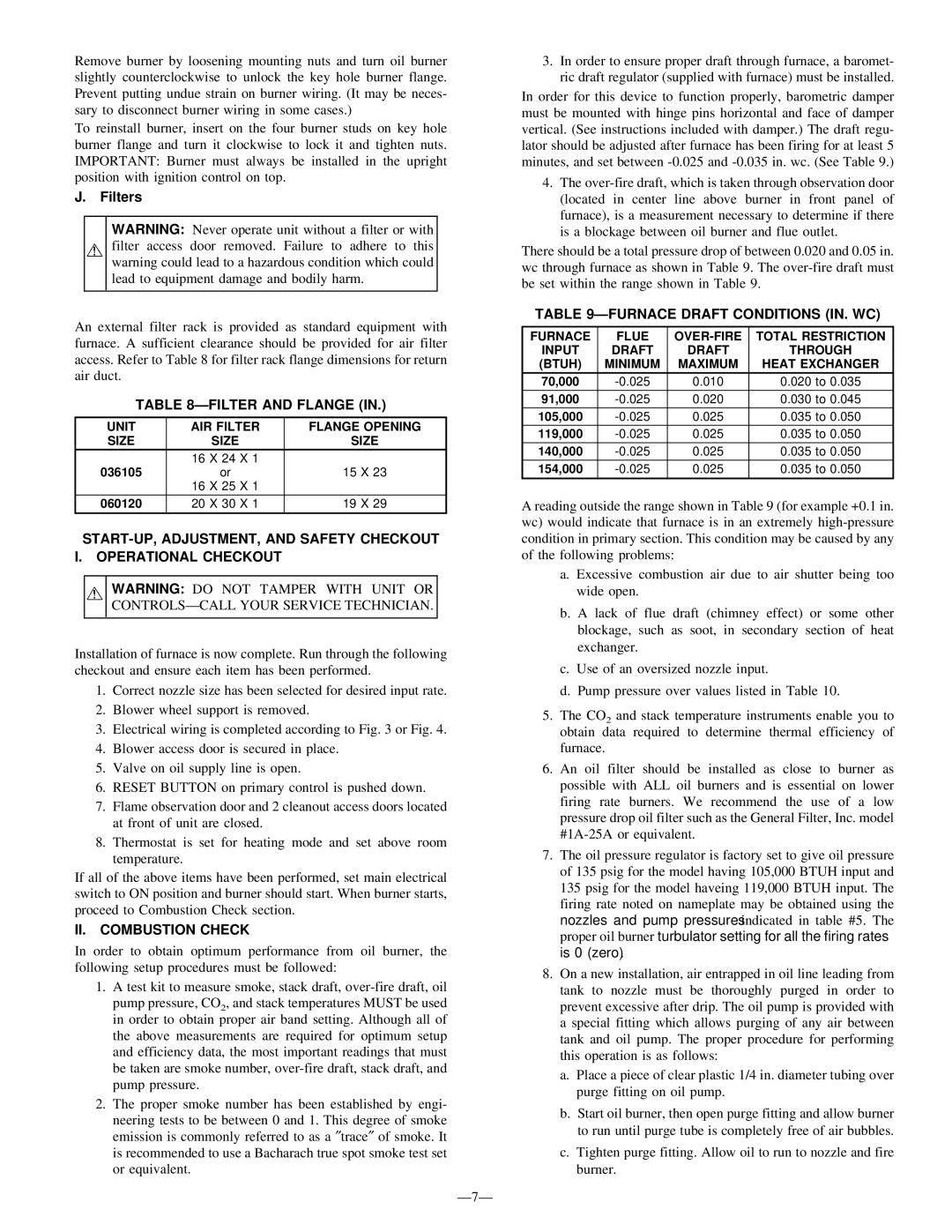

An external filter rack is provided as standard equipment with furnace. A sufficient clearance should be provided for air filter access. Refer to Table 8 for filter rack flange dimensions for return air duct.

TABLE 8—FILTER AND FLANGE (IN.)

UNIT | AIR FILTER | FLANGE OPENING |

SIZE | SIZE | SIZE |

036105 | 16 X 24 X 1 |

|

or | 15 X 23 | |

| 16 X 25 X 1 |

|

060120 | 20 X 30 X 1 | 19 X 29 |

WARNING: DO NOT TAMPER WITH UNIT OR

Installation of furnace is now complete. Run through the following checkout and ensure each item has been performed.

1.Correct nozzle size has been selected for desired input rate.

2.Blower wheel support is removed.

3.Electrical wiring is completed according to Fig. 3 or Fig. 4.

4.Blower access door is secured in place.

5.Valve on oil supply line is open.

6.RESET BUTTON on primary control is pushed down.

7.Flame observation door and 2 cleanout access doors located at front of unit are closed.

8.Thermostat is set for heating mode and set above room temperature.

If all of the above items have been performed, set main electrical switch to ON position and burner should start. When burner starts, proceed to Combustion Check section.

II. COMBUSTION CHECK

In order to obtain optimum performance from oil burner, the following setup procedures must be followed:

1.A test kit to measure smoke, stack draft,

pump pressure, CO2, and stack temperatures MUST be used in order to obtain proper air band setting. Although all of the above measurements are required for optimum setup and efficiency data, the most important readings that must be taken are smoke number,

2.The proper smoke number has been established by engi-

neering tests to be between 0 and 1. This degree of smoke emission is commonly referred to as a ″ trace″ of smoke. It is recommended to use a Bacharach true spot smoke test set or equivalent.

3.In order to ensure proper draft through furnace, a baromet- ric draft regulator (supplied with furnace) must be installed.

In order for this device to function properly, barometric damper must be mounted with hinge pins horizontal and face of damper vertical. (See instructions included with damper.) The draft regu- lator should be adjusted after furnace has been firing for at least 5 minutes, and set between

4.The

There should be a total pressure drop of between 0.020 and 0.05 in. wc through furnace as shown in Table 9. The

TABLE 9—FURNACE DRAFT CONDITIONS (IN. WC)

FURNACE | FLUE | TOTAL RESTRICTION | |

INPUT | DRAFT | DRAFT | THROUGH |

(BTUH) | MINIMUM | MAXIMUM | HEAT EXCHANGER |

70,000 | 0.010 | 0.020 to 0.035 | |

91,000 | 0.020 | 0.030 to 0.045 | |

105,000 | 0.025 | 0.035 to 0.050 | |

119,000 | 0.025 | 0.035 to 0.050 | |

140,000 | 0.025 | 0.035 to 0.050 | |

154,000 | 0.025 | 0.035 to 0.050 |

A reading outside the range shown in Table 9 (for example +0.1 in. wc) would indicate that furnace is in an extremely

a. Excessive combustion air due to air shutter being too wide open.

b. A lack of flue draft (chimney effect) or some other blockage, such as soot, in secondary section of heat exchanger.

c.Use of an oversized nozzle input.

d.Pump pressure over values listed in Table 10.

5.The CO2 and stack temperature instruments enable you to obtain data required to determine thermal efficiency of furnace.

6.An oil filter should be installed as close to burner as possible with ALL oil burners and is essential on lower firing rate burners. We recommend the use of a low pressure drop oil filter such as the General Filter, Inc. model

7.The oil pressure regulator is factory set to give oil pressure of 135 psig for the model having 105,000 BTUH input and 135 psig for the model haveing 119,000 BTUH input. The firing rate noted on nameplate may be obtained using the nozzles and pump pressures indicated in table #5. The proper oil burner turbulator setting for all the firing rates is 0 (zero).

8.On a new installation, air entrapped in oil line leading from tank to nozzle must be thoroughly purged in order to prevent excessive after drip. The oil pump is provided with

aspecial fitting which allows purging of any air between tank and oil pump. The proper procedure for performing this operation is as follows:

a.Place a piece of clear plastic 1/4 in. diameter tubing over purge fitting on oil pump.

b.Start oil burner, then open purge fitting and allow burner to run until purge tube is completely free of air bubbles.

c.Tighten purge fitting. Allow oil to run to nozzle and fire burner.