3. Remove air filter from furnace.

•AIR FILTER LOCATED IN BLOWER COMPARTMENT:

a)Slide filter retainer sideways un- til it is free of latch. (See Fig. 24)

b)Gently remove air filter and carefully turn the dirty side up (if dirty) to avoid spilling dirt from the filter. (see Fig. 25)

•AIR FILTER LOCATED IN FIL- TER CABINET:

a)Slide air filter out of furnace. Keep dirty side up (if dirty) to avoid spilling dirt. (See Fig. 32 and 33)

26

4. Inspect the filter. If torn, replace it. NOTE: If washable filter that was shipped with the furnace has been re- placed by:

a)Factory specified disposable media filter – Do not clean. If dirty, replace only with media filter having the same part num- ber and size. Install with airflow direction arrow pointing to- wards blower.

b)Electronic air cleaner (EAC) – Refer to EAC owner’s Manual for maintenance information.

5.Wash filter (if dirty) in sink, bath- tub, or outside with a garden hose. Always use cold tap water. A mild liquid detergent may be used if nec- essary. Spray water through filter in the opposite direction of airflow.

Allow filter to dry.

6.Reinstall clean air filter

7.Reinstall filter retainer (for blower compartment locations only)

8.Replace control and blower doors (See Fig. 16 and 17) or filter cabinet door (Fig. 34 and 35)

9.Turn on electrical supply to furnace (see Fig 18).

NOTE: For upflow models

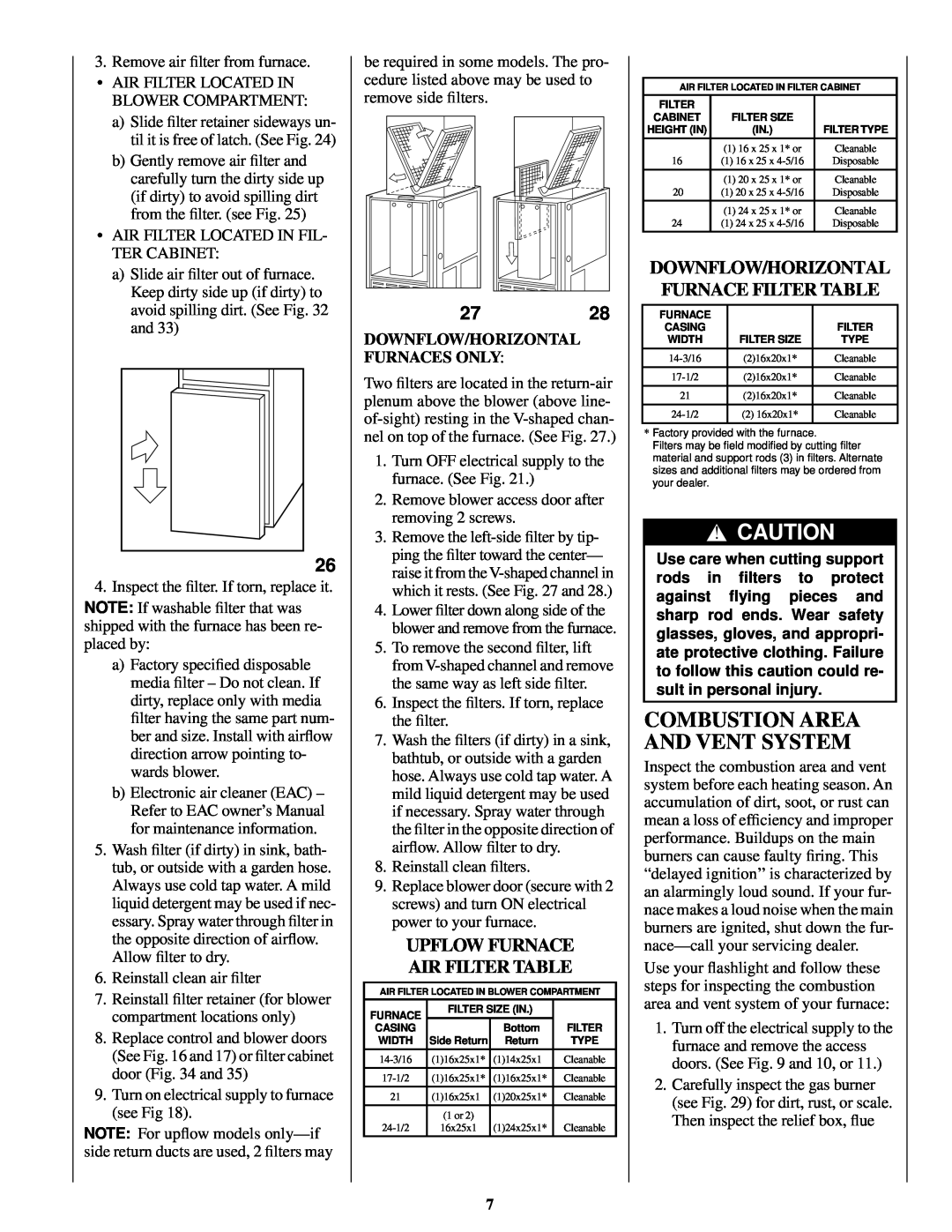

be required in some models. The pro- cedure listed above may be used to remove side filters.

2728

DOWNFLOW/HORIZONTAL FURNACES ONLY:

Two filters are located in the

1.Turn OFF electrical supply to the furnace. (See Fig. 21.)

2.Remove blower access door after removing 2 screws.

3.Remove the

4.Lower filter down along side of the blower and remove from the furnace.

5.To remove the second filter, lift from

6.Inspect the filters. If torn, replace the filter.

7.Wash the filters (if dirty) in a sink, bathtub, or outside with a garden hose. Always use cold tap water. A mild liquid detergent may be used if necessary. Spray water through the filter in the opposite direction of airflow. Allow filter to dry.

8.Reinstall clean filters.

9.Replace blower door (secure with 2 screws) and turn ON electrical power to your furnace.

UPFLOW FURNACE

AIR FILTER TABLE

AIR FILTER LOCATED IN BLOWER COMPARTMENT

FURNACE | FILTER SIZE (IN.) |

| |

|

|

| |

CASING |

| Bottom | FILTER |

WIDTH | Side Return | Return | TYPE |

|

|

|

|

(1)16x25x1* | (1)14x25x1* | Cleanable | |

|

|

|

|

(1)16x25x1* | (1)16x25x1** | Cleanable | |

|

|

|

|

21 | (1)16x25x1* | (1)20x25x1* | Cleanable |

|

|

|

|

| (1 or 2) |

|

|

16x25x1 | (1)24x25x1** | Cleanable | |

7

AIR FILTER LOCATED IN FILTER CABINET

FILTER |

|

|

CABINET | FILTER SIZE |

|

HEIGHT (IN) | (IN.) | FILTER TYPE |

|

|

|

| (1) 16 x 25 x 1* or | Cleanable |

16 | (1) 16 x 25 x | Disposable |

|

|

|

| (1) 20 x 25 x 1* or | Cleanable |

20 | (1) 20 x 25 x | Disposable |

| (1) 24 x 25 x 1* or | Cleanable |

24 | (1) 24 x 25 x | Disposable |

|

|

|

DOWNFLOW/HORIZONTAL FURNACE FILTER TABLE

FURNACE |

|

|

CASING |

| FILTER |

WIDTH | FILTER SIZE | TYPE |

|

|

|

(2)16x20x1* | Cleanable | |

|

|

|

(2)16x20x1* | Cleanable | |

|

|

|

21 | (2)16x20x1* | Cleanable |

|

|

|

(2) 16x20x1* | Cleanable | |

|

|

|

*Factory provided with the furnace.

Filters may be field modified by cutting filter material and support rods (3) in filters. Alternate sizes and additional filters may be ordered from your dealer.

!CAUTION

Use care when cutting support rods in filters to protect against flying pieces and sharp rod ends. Wear safety glasses, gloves, and appropri- ate protective clothing. Failure to follow this caution could re- sult in personal injury.

COMBUSTION AREA AND VENT SYSTEM

Inspect the combustion area and vent system before each heating season. An accumulation of dirt, soot, or rust can mean a loss of efficiency and improper performance. Buildups on the main burners can cause faulty firing. This “delayed ignition’’ is characterized by an alarmingly loud sound. If your fur- nace makes a loud noise when the main burners are ignited, shut down the fur-

Use your flashlight and follow these steps for inspecting the combustion area and vent system of your furnace:

1.Turn off the electrical supply to the furnace and remove the access doors. (See Fig. 9 and 10, or 11.)

2.Carefully inspect the gas burner (see Fig. 29) for dirt, rust, or scale. Then inspect the relief box, flue