574B specifications

The Bryant 574B is a remarkable air conditioning unit renowned for its efficient cooling performance and advanced technology. Designed for both residential and light commercial applications, this model stands out in the market for its durability and energy efficiency.One of the primary features of the Bryant 574B is its wide capacity range. This unit is designed to cater to various room sizes, allowing homeowners to select an appropriate model that best suits their cooling needs. The 574B series comes with efficient cooling capacities, ensuring that indoor spaces remain comfortable even during the hottest summer months.

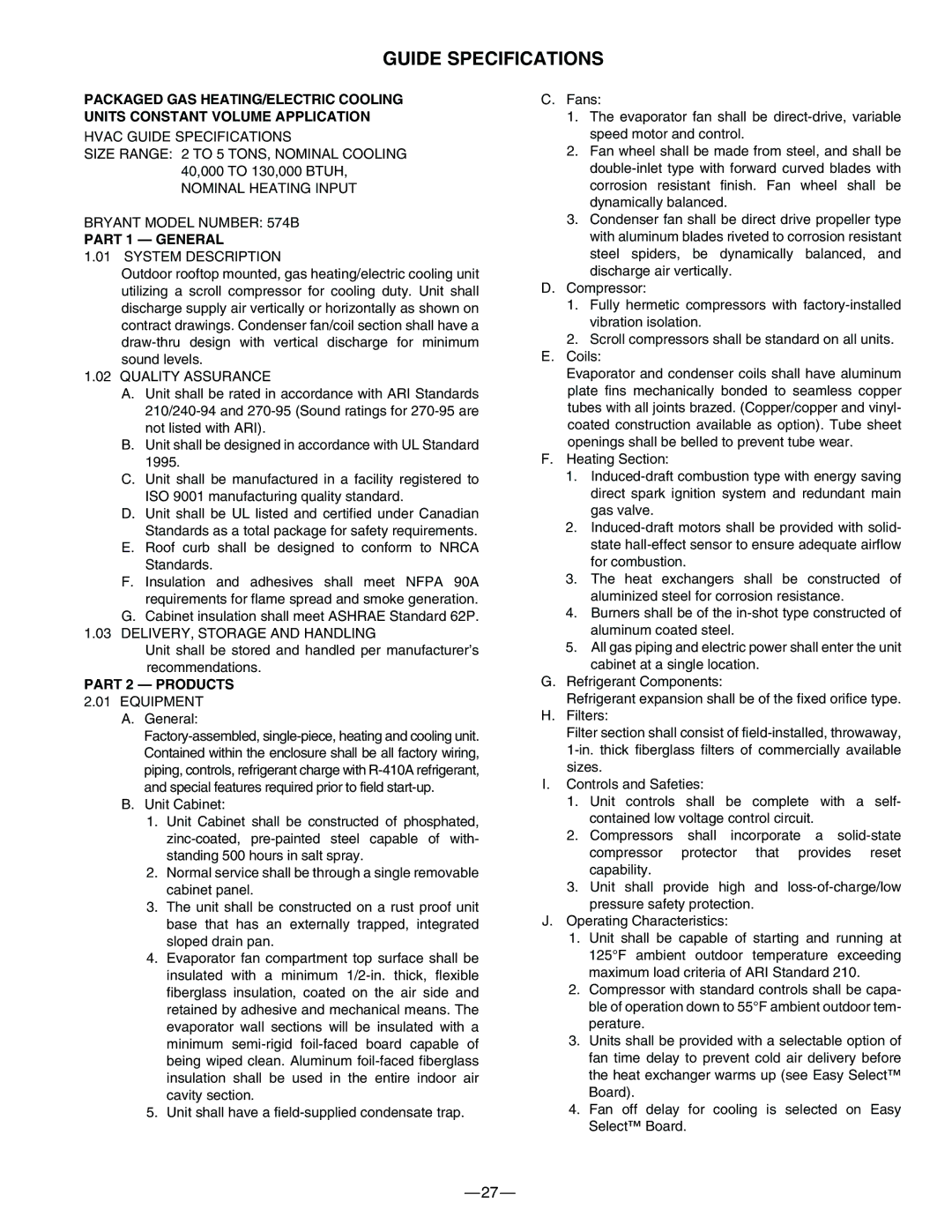

In terms of technology, the Bryant 574B integrates advanced refrigeration systems coupled with environmentally conscious refrigerants. The unit utilizes R-410A refrigerant, which is known for its efficiency and energy conservation properties, making it a more environmentally friendly choice compared to older models that used R-22 refrigerant. This transitions not only help in achieving better energy ratings but also align with modern regulations concerning refrigerants.

Another notable characteristic of the Bryant 574B is its impressive Seasonal Energy Efficiency Ratio (SEER). A higher SEER rating translates to lower energy consumption, which is a significant advantage for homeowners looking to minimize their electricity bills. The 574B boasts a SEER rating that meets or exceeds the standards set by the Department of Energy, showcasing its commitment to energy efficiency.

Durability is also a hallmark of the Bryant 574B air conditioner. Its construction includes a robust cabinet designed to withstand harsh weather conditions, ensuring longevity and consistent performance. The unit is equipped with a protective coating to prevent rust and corrosion, further extending its lifespan.

Moreover, the Bryant 574B features easy installation and maintenance. The design allows for straightforward setup, which can significantly reduce installation time. Additionally, the unit comes with an accessible maintenance panel, making routine checks and servicing hassle-free.

In summary, the Bryant 574B is a high-performing air conditioning system characterized by its efficiency, environmentally friendly design, and durability. With its advanced technologies and user-friendly features, it is a reliable choice for those seeking comfort and savings in their cooling systems.