Sweat Connection

!CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or improper operation.

Service valves must be wrapped in a

Use refrigeration grade tubing. Service valves are closed from factory and ready for brazing. After wrapping service valve with a wet cloth, braze sweat connections using industry accepted methods and materials. Consult local code requirements. Refrigerant tubing and indoor coil are now ready for leak testing. This check should include all field and factory joints.

Table 1 – Refrigerant Connections and Recommended Liquid

and Vapor Tube Diameters (In.)

113A

| LIQUID | RATED VAPOR* | |

UNIT SIZE (SERIES) | Connection | Connection | Tube |

| & Max. Tube | Diameter | Diameter |

| Diameter | ||

|

|

| |

018, 024 (Series C) | 3/8 | 5/8 | 5/8 |

018, 024 (Series D) | 3/8 | 3/4 | 3/4 |

030 | 3/8 | 3/4 | 3/4 |

036 (Series D) | 3/8 | 3/4 | 3/4 |

036 (Series E) | 3/8 | 7/8 | 7/8 |

042, 048 | 3/8 | 7/8 | 7/8 |

060 | 3/8 | 7/8 | |

|

|

|

|

| 114A |

|

|

| LIQUID | RATED VAPOR* | |

UNIT SIZE | Connection | Connection | Tube |

| & Max. Tube | Diameter | Diameter |

| Diameter | ||

|

|

| |

018, 024 | 3/8 | 5/8 | 5/8 |

030, 036 | 3/8 | 3/4 | 3/4 |

042, 048, 049 | 3/8 | 7/8 | 7/8 |

060, 061 | 3/8 | 7/8 | |

|

|

|

|

| 116B |

|

|

| LIQUID | RATED VAPOR* | |

UNIT SIZE | Connection | Connection | Tube |

| & Max. Tube | Diameter | Diameter |

| Diameter | ||

|

|

| |

018, 024 | 3/8 | 3/4 | 3/4 |

030 | 3/8 | 3/4 | 3/4 |

036 | 3/8 | 7/8 | 7/8 |

042, 048 | 3/8 | 7/8 | 7/8 |

060 | 3/8 | 7/8 | |

*Units are rated with 25 ft. (7.6 m) of lineset. See Product Data sheet for performance data when using different size and length linesets.

Notes:

1.Do not apply capillary tube or fixed orifice indoor coils to these units.

2.For Tubing Set lengths between 80 and 200 ft. (24.38 and 60.96 m) horizontal or 35 ft. (10.7 m) vertical differential 250 ft. (76.2 m) Total Equivalent Length), refer to the Residential Piping and Longline Guide

3.For alternate liquid line options on 018

Install Liquid-Line Filter Drier Indoor

!CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or improper operation.

1.Installation of filter drier in liquid line is required.

2.Filter drier must be wrapped in a

Refer to Fig. 3 and install filter drier as follows:

1.Braze

2.Wrap filter drier with damp cloth.

3.Braze filter drier to above

4.Connect and braze liquid refrigerant tube to the filter drier.

| A05178 |

|

| |

| Fig. 3 - Liquid Line Filter Drier |

|

| |

|

| /116B | ||

Evacuate Refrigerant Tubing and Indoor Coil |

| |||

|

|

| ||

! | CAUTION | |||

| / 114A | |||

UNIT DAMAGE HAZARD |

| |||

| 113A | |||

Failure to follow this caution may result in equipment |

| |||

damage or improper operation. |

| |||

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using the recommended deep vacuum method of 500 microns. The alternate triple evacuation method may be used (see triple evacuation procedure in service manual). Always break a vacuum with dry nitrogen.

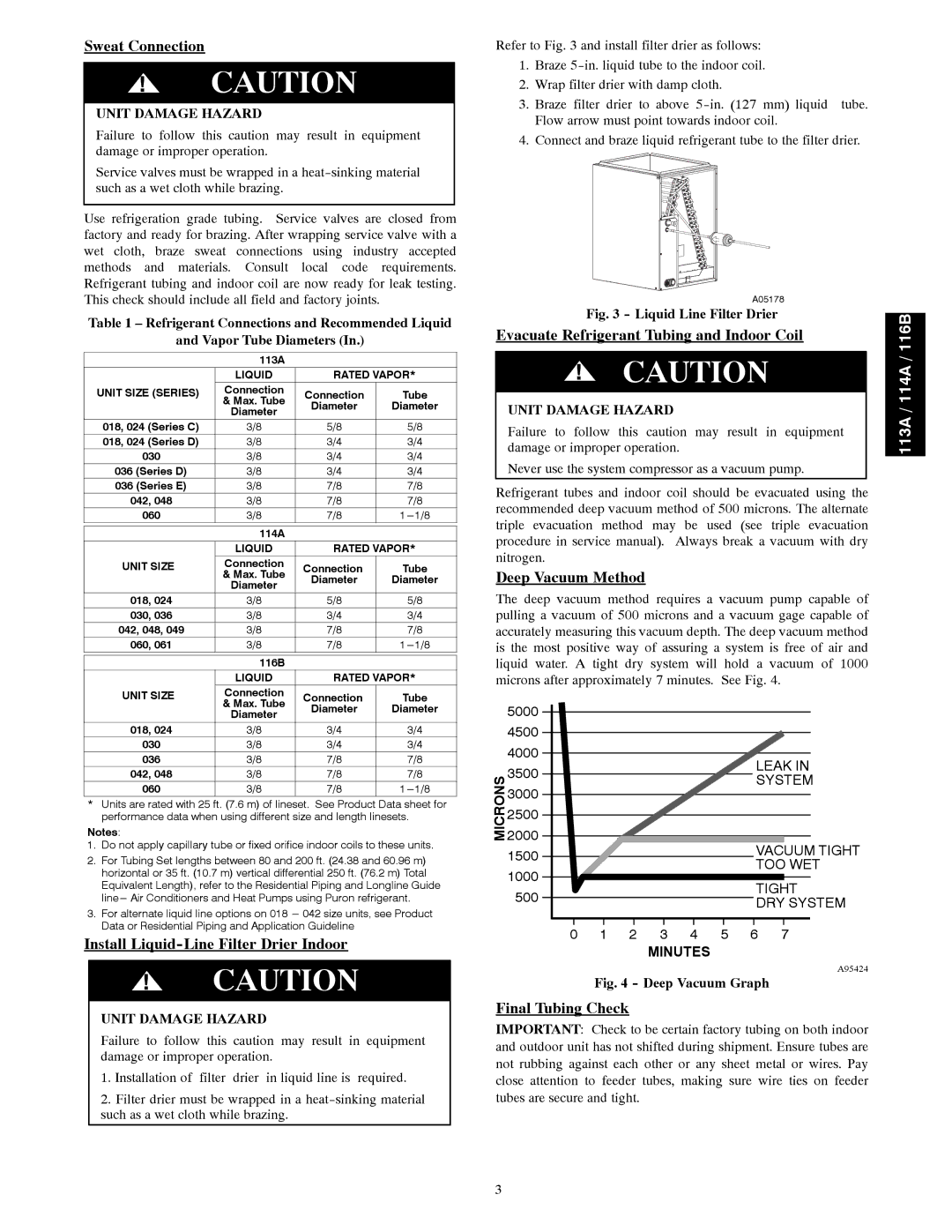

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of pulling a vacuum of 500 microns and a vacuum gage capable of accurately measuring this vacuum depth. The deep vacuum method is the most positive way of assuring a system is free of air and liquid water. A tight dry system will hold a vacuum of 1000 microns after approximately 7 minutes. See Fig. 4.

5000 |

|

|

|

|

|

|

|

4500 |

|

|

|

|

|

|

|

4000 |

|

|

|

|

| LEAK IN | |

3500 |

|

|

|

|

| ||

|

|

|

|

| SYSTEM | ||

3000 |

|

|

|

|

| ||

|

|

|

|

|

|

| |

2500 |

|

|

|

|

|

|

|

MICRONS2000 |

|

|

|

|

| VACUUM TIGHT | |

1500 |

|

|

|

|

| ||

|

|

|

|

| TOO WET | ||

1000 |

|

|

|

|

| ||

|

|

|

|

| TIGHT | ||

500 |

|

|

|

|

| ||

|

|

|

|

| DRY SYSTEM | ||

|

|

|

|

|

| ||

0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|

|

| MINUTES |

|

|

| |

|

|

|

|

|

|

| A95424 |

Fig. 4 - Deep Vacuum Graph

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both indoor and outdoor unit has not shifted during shipment. Ensure tubes are not rubbing against each other or any sheet metal or wires. Pay close attention to feeder tubes, making sure wire ties on feeder tubes are secure and tight.

3