ULTRA-2 PAF, ULTRA-2 PAFA specifications

The Bunn ULTRA-2 PAFA and ULTRA-2 PAF are sophisticated machines designed to meet the demands of high-volume beverage service. Renowned for their reliability and efficiency, these machines are perfect for cafes, restaurants, and convenience stores looking to dispense delicious slush beverages quickly.A key feature of the Bunn ULTRA-2 series is its ability to produce two flavors of frozen beverages simultaneously. This dual flavor capability greatly enhances beverage offerings, allowing establishments to attract a wider range of customers. Whether it’s classic slush flavors or innovative mixes, the ULTRA-2 ensures a diverse menu that appeals to all ages.

The machines are equipped with an advanced refrigeration system that ensures the optimal freezing temperature for slush preparation. The ULTRA-2 features an innovative blend of high-efficiency cooling technology and reliable components, which not only reduce energy consumption but also maintain consistent product quality. The air-cooled system eliminates the need for water lines, simplifying installation and maintenance.

One of the standout characteristics of the Bunn ULTRA-2 PAFA and PAF units is their user-friendly interface. The intuitive controls allow staff to operate the machine effortlessly, minimizing training time and maximizing productivity. Digital display panels provide real-time insights into product levels and machine status, allowing for prompt action in case of low supplies or potential issues.

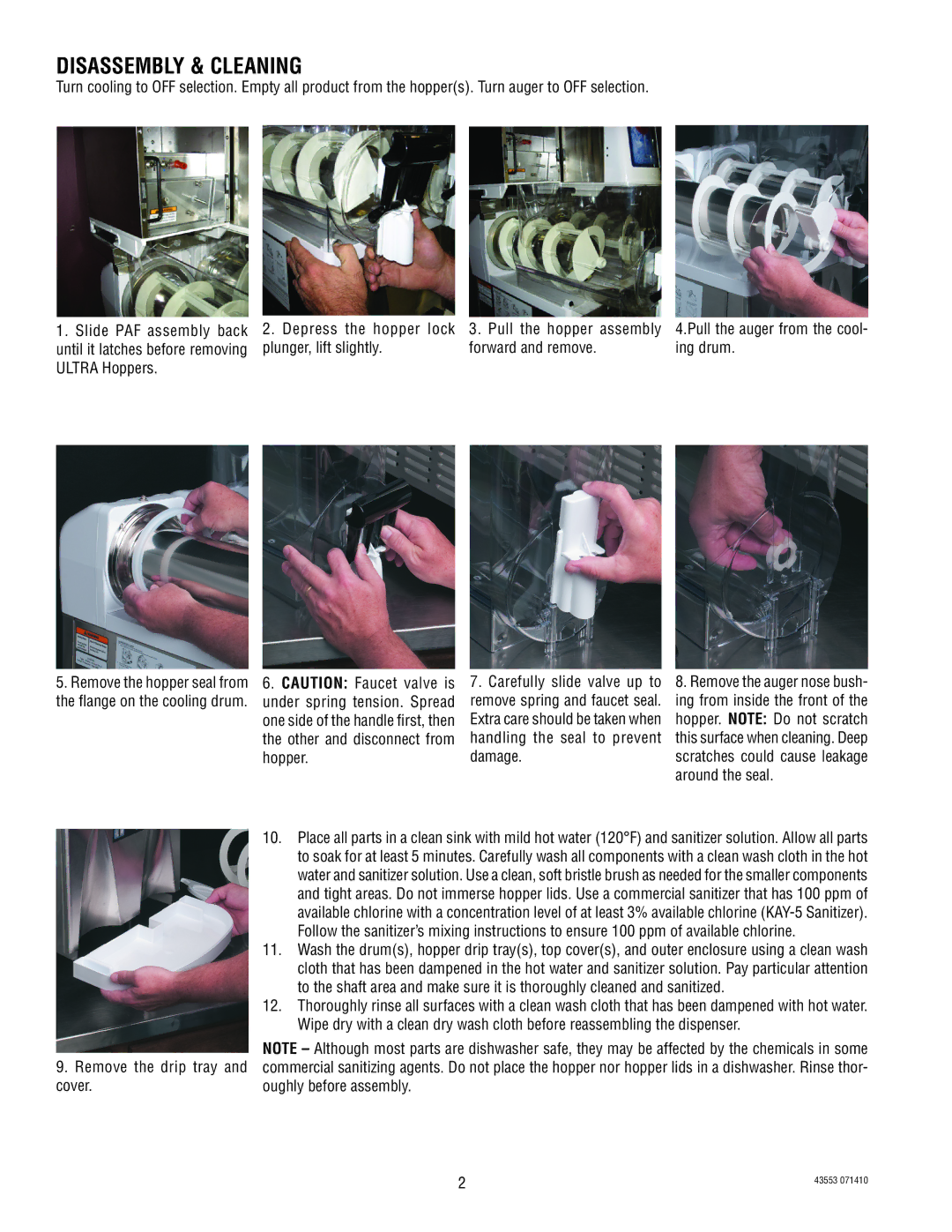

In addition to performance, the ULTRA-2 series emphasizes hygiene and ease of cleaning. The removable parts and smooth surfaces enable quick and thorough cleaning processes, ensuring that the machine remains in top condition and is safe for food service. This attention to cleanliness helps businesses maintain health regulations and ensure customer satisfaction.

Versatility is another hallmark of the Bunn ULTRA-2 PAFA and PAF. Their design accommodates various types of mixes, from traditional syrups to more complex blended ingredients. This flexibility allows businesses to innovate and introduce seasonal or promotional flavors without significant changes to their equipment.

In summary, the Bunn ULTRA-2 PAFA and PAF are ideal solutions for establishments looking to offer high-quality frozen beverages. With their dual flavor capability, energy-efficient technology, user-friendly controls, and easy maintenance, these machines are a valuable asset for any beverage service operation. Their ability to create a diverse and appealing beverage menu can significantly enhance customer experience, making them an excellent investment for businesses aiming to thrive in the competitive food service landscape.