DOE specifications

Burnham DOE, or Burnham Direct Oil Equipment, is a prominent name in the heating systems industry, particularly known for its innovative solutions tailored for residential and commercial heating needs. Rooted in a legacy of craftsmanship and engineering excellence, Burnham DOE stands out for its commitment to energy efficiency, reliability, and user-friendly design.One of the main features of Burnham DOE products is their advanced burner technology. The company integrates sophisticated combustion systems that optimize fuel usage while minimizing emissions. This approach not only helps in reducing operational costs for users but also aligns with modern environmental standards, fostering a more sustainable heating solution.

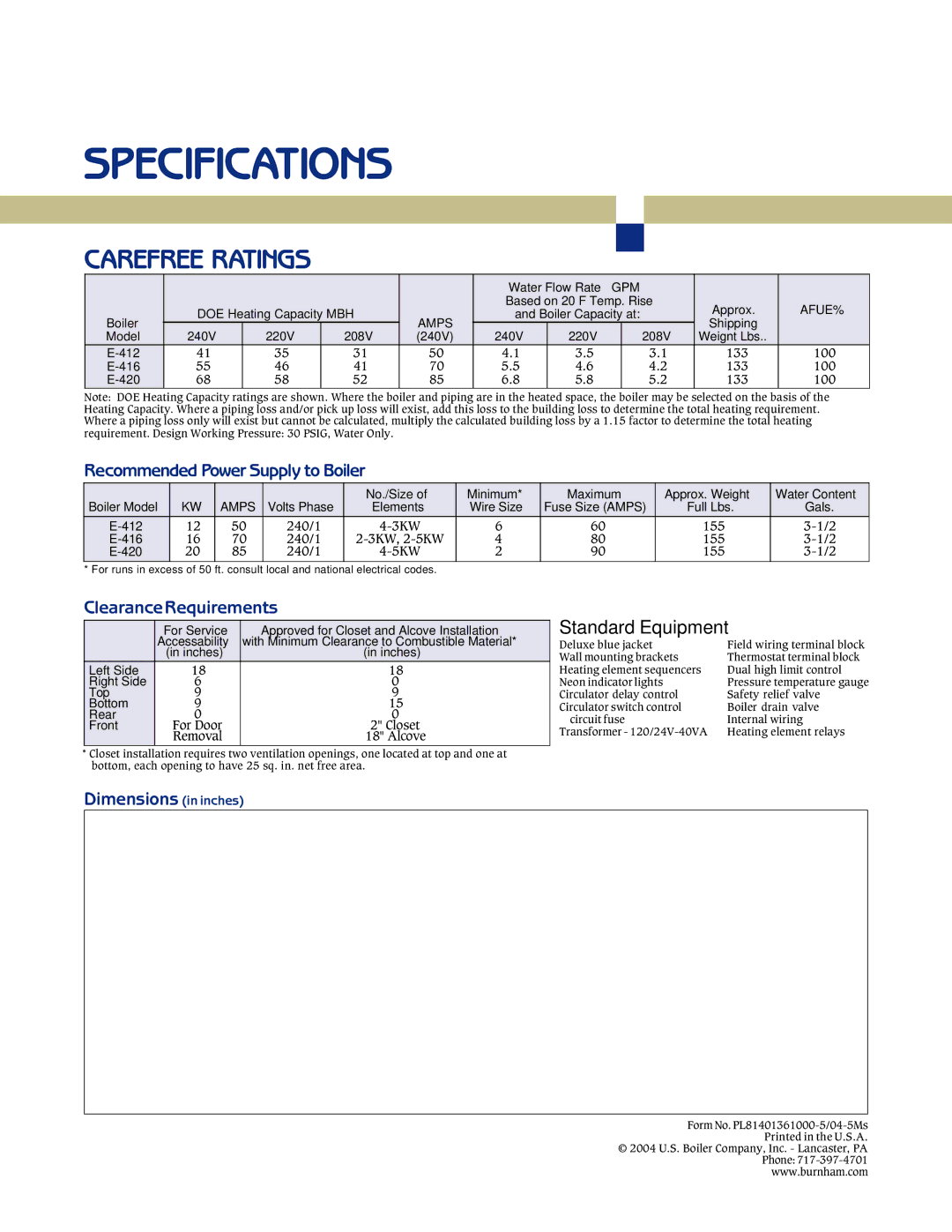

Additionally, the company offers various boiler types, including commercial and residential models, designed to cater to diverse heating requirements. These boilers incorporate both condensing and non-condensing designs, allowing customers to choose the system that best fits their efficiency needs and budget. The condensing boilers are particularly noteworthy for their ability to capture and utilize waste heat, achieving higher overall efficiency and reduced energy consumption.

Burnham DOE places a strong emphasis on durability and build quality. Their products are constructed from high-grade materials designed to withstand various operational stresses. This results in longer service life and lower maintenance costs, which is a crucial consideration for both homeowners and business operators looking to maximize their investment.

In terms of technology, Burnham DOE utilizes smart controls and monitoring systems that enhance user interaction and system management. These intelligent features allow for programmable settings, remote access, and real-time performance data, giving users the ability to optimize their heating operations effortlessly.

The company also provides comprehensive support and resources for installation and maintenance, ensuring that customers have access to necessary expertise throughout the lifecycle of the product. This service-oriented approach has solidified Burnham DOE’s reputation as a trusted partner in the heating industry.

In summary, Burnham DOE combines innovative technology with exceptional craftsmanship to deliver efficient, durable heating solutions. With features like advanced burner systems, various boiler designs, and user-friendly controls, the company remains at the forefront of the heating industry, continually adapting to meet the evolving needs of its customers.