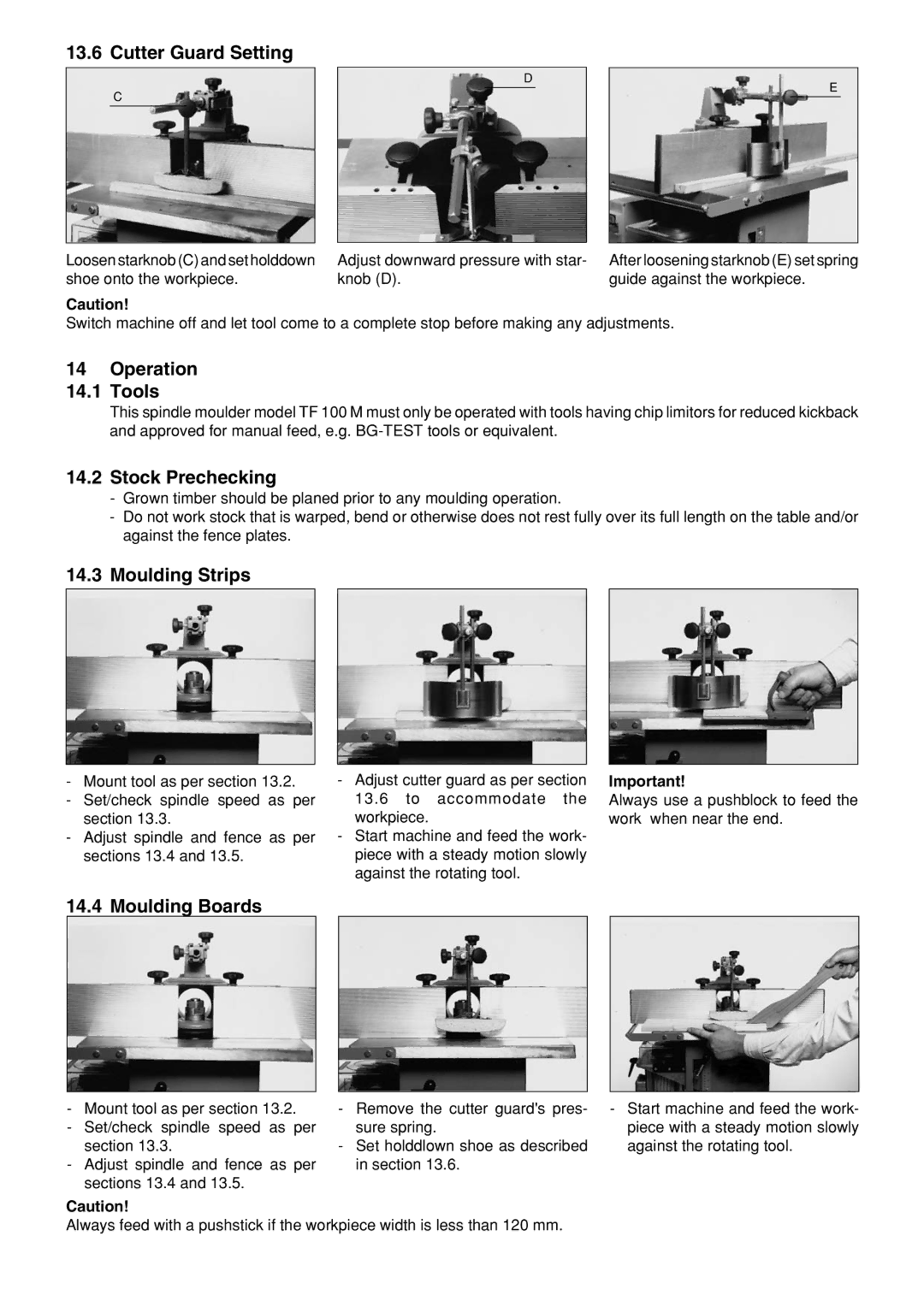

13.6 Cutter Guard Setting

C

D

E

Loosen starknob (C) and set holddown | Adjust downward pressure with star- | After loosening starknob (E) set spring |

shoe onto the workpiece. | knob (D). | guide against the workpiece. |

Caution!

Switch machine off and let tool come to a complete stop before making any adjustments.

14Operation

14.1 Tools

This spindle moulder model TF 100 M must only be operated with tools having chip limitors for reduced kickback and approved for manual feed, e.g.

14.2Stock Prechecking

-Grown timber should be planed prior to any moulding operation.

-Do not work stock that is warped, bend or otherwise does not rest fully over its full length on the table and/or against the fence plates.

14.3Moulding Strips

-Mount tool as per section 13.2.

-Set/check spindle speed as per section 13.3.

-Adjust spindle and fence as per sections 13.4 and 13.5.

-Adjust cutter guard as per section 13.6 to accommodate the workpiece.

-Start machine and feed the work- piece with a steady motion slowly against the rotating tool.

Important!

Always use a pushblock to feed the work when near the end.

14.4 Moulding Boards

- Mount tool as per section 13.2. | - | Remove the cutter guard's pres- | |

- | Set/check spindle speed as per |

| sure spring. |

| section 13.3. | - | Set holddlown shoe as described |

- | Adjust spindle and fence as per |

| in section 13.6. |

| sections 13.4 and 13.5. |

|

|

Caution!

Always feed with a pushstick if the workpiece width is less than 120 mm.

- Start machine and feed the work- piece with a steady motion slowly against the rotating tool.