8Safety Information

-Always follow the instructions in this manual.

-Use only tools approved for manual feed

-Never exceed the max. permissible tool speed.

-Follow the specific instructions supplied with the tool by the tool maker.

-Do not use tools of larger diameter than specified for this machine.

-Do not work stock with smaller or larger dimensions than specified in this manual.

-Always disconnect from power before servicing.

-Always let the spindle come to a complete stop before removing any obstructions.

-Fence, fence plates and cutter guard have to be set as required for the job on hand.

-Always feed strips and other small workpieces with a pushstick or pushblock.

-Select a suitable spindle speed (see section 11.0 of this manual).

-Persons under the age of 16 should not operate this machine.

-Ensure you know how to switch off the machine in an emergency.

-Always wear eye protection.

9Workpiece Dimensions

-Workpieces shorter than 200 mm must not be worked on this spindle moulder unless a suitable feeding jig is used for support.

-Support workpieces longer than 1000 mm with table extensions (optional accessory) or roller stands to keep them from falling off the machine's table.

-The maximum workpiece width (for boards) should not exceed 500 mm.

10Scope Of Application

-The Spindle Moulder model TF 100 M is designed for moulding workpieces of timber and/or timber derived products, e.g. chip or particle board, fibre boards and plywood, either plain or laminated/faced with plastics.

-Moulding on endgrain, e.g. making tenons, requires a sliding carriage (optional accessory) for firm guiding.

-

-Moulding of contoured workpieces is not permitted with this spindle moulder.

-Climb cutting operations are not permitted with this spindle moulder.

11Tool Dimensions/Cutting Speeds

In order to reduce the risk of kickback the cutting speed of the tool used must be greater than 35 m/s.

-Moulding tools cannot safely be used at the lowest speed setting of 4000

-For a spindle speed of 6000

-For a spindle speed of 7500

-At both spindle speeds suitable for moulding (6000 and 7500

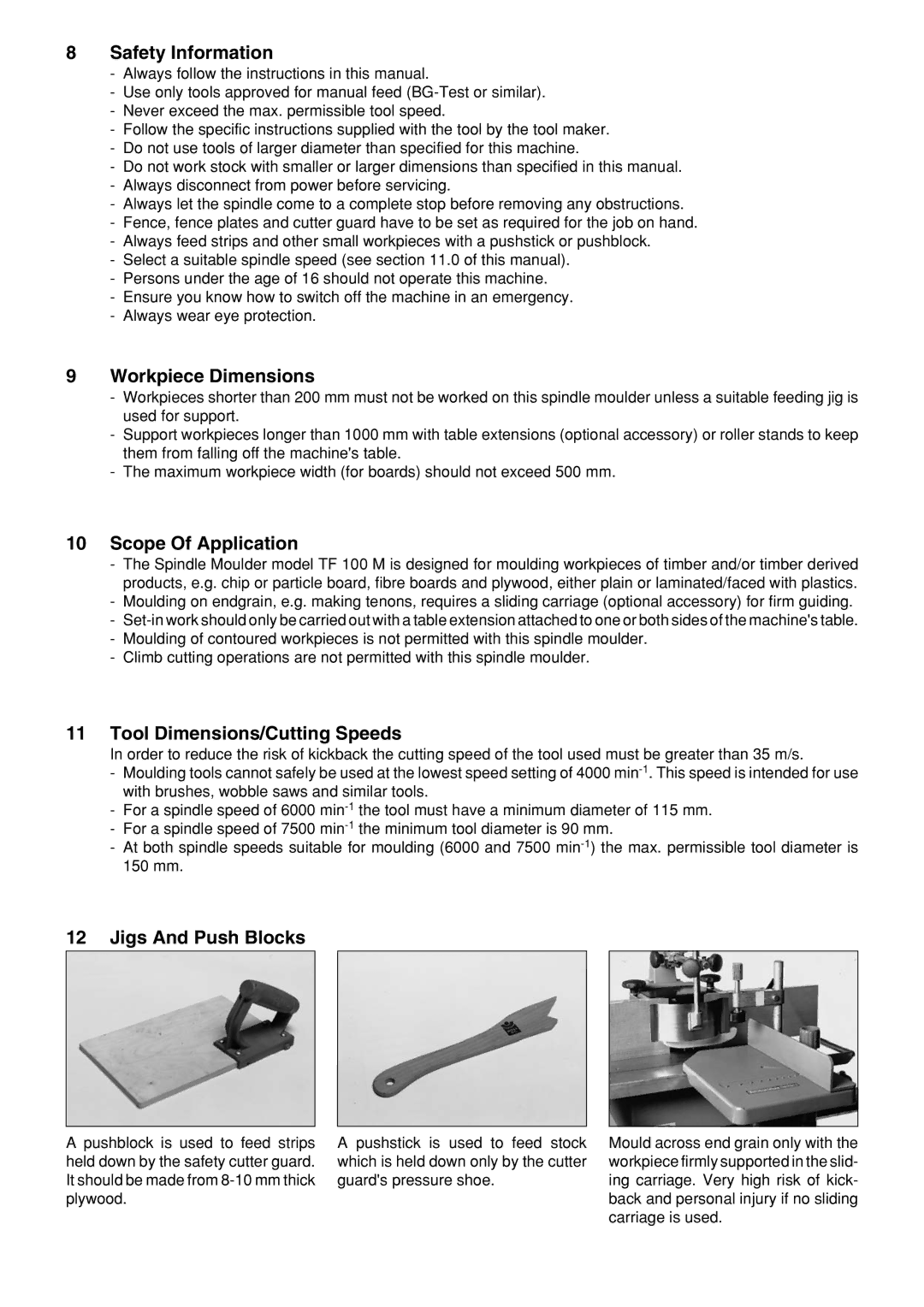

12 Jigs And Push Blocks

A pushblock is used to feed strips held down by the safety cutter guard. It should be made from

A pushstick is used to feed stock which is held down only by the cutter guard's pressure shoe.

Mould across end grain only with the workpiece firmly supported in the slid- ing carriage. Very high risk of kick- back and personal injury if no sliding carriage is used.