ENG

Contents |

| 11 | Tool Dimensions/Cutting Speeds |

1 | Specifications | 12 | Jigs And Push Blocks |

2 | User Responsibility | 13 | Controls |

3 | Standard Delivery | 13.1 | Definitions |

4 | Optional Accessories | 13.2 | Mounting A Tool |

5 | Final Assembly | 13.3 | Spindle Speed Setting/Changing |

6 | Installation | 13.4 | Tool Height Setting |

7 | Commissioning | 13.5 | Fence And Fence Plate Setting |

7.1 | 13.6 | Cutter Guard Setting | |

7.2 | 14 | Operation | |

7.3 | Direction Of Rotation | 14.1 | Tools |

7.4 | Switch | 14.2 | Stock Prechecking |

7.5 | Overload Protection | 14.3 | Moulding Strips |

7.6 | 14.4 | Moulding Boards | |

7.7 | Dust Collection | 14.5 | Making Tenons |

7.8 | Dust Collector Automatic Start | 14.6 | |

8 | Safety Information | 15 | Care And Maintenance |

9Workpiece Dimensions

10Scope Of Application

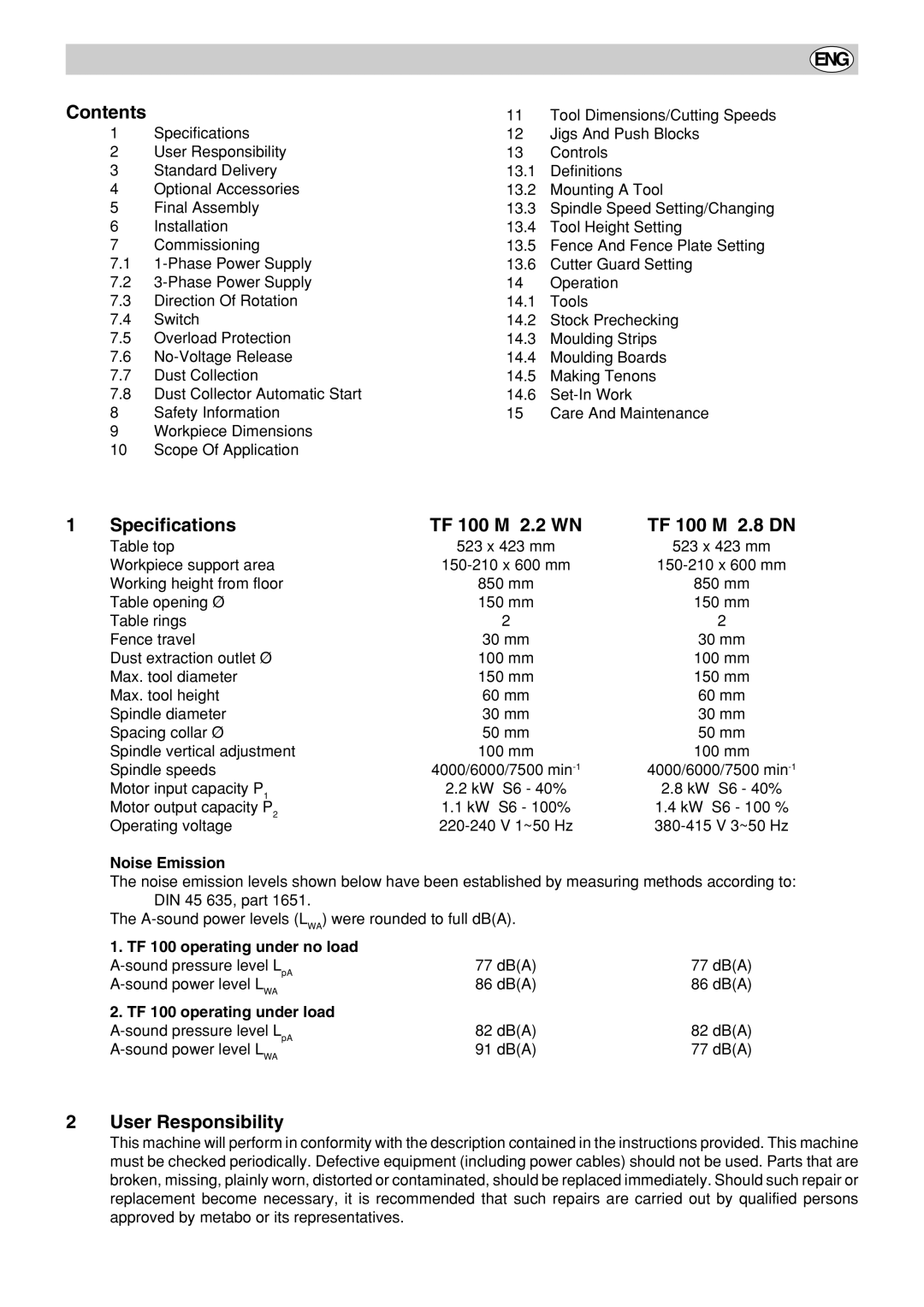

1 Specifications | TF 100 M 2.2 WN | TF 100 M 2.8 DN |

Table top | 523 x 423 mm | 523 x 423 mm |

Workpiece support area | ||

Working height from floor | 850 mm | 850 mm |

Table opening Ø | 150 mm | 150 mm |

Table rings | 2 | 2 |

Fence travel | 30 mm | 30 mm |

Dust extraction outlet Ø | 100 mm | 100 mm |

Max. tool diameter | 150 mm | 150 mm |

Max. tool height | 60 mm | 60 mm |

Spindle diameter | 30 mm | 30 mm |

Spacing collar Ø | 50 mm | 50 mm |

Spindle vertical adjustment | 100 mm | 100 mm |

Spindle speeds | 4000/6000/7500 | 4000/6000/7500 |

Motor input capacity P1 | 2.2 kW S6 - 40% | 2.8 kW S6 - 40% |

Motor output capacity P2 | 1.1 kW S6 - 100% | 1.4 kW S6 - 100 % |

Operating voltage |

Noise Emission

The noise emission levels shown below have been established by measuring methods according to: DIN 45 635, part 1651.

The

1. TF 100 operating under no load |

|

|

77 dB(A) | 77 dB(A) | |

86 dB(A) | 86 dB(A) | |

2. TF 100 operating under load |

|

|

82 dB(A) | 82 dB(A) | |

91 dB(A) | 77 dB(A) |

2 User Responsibility

This machine will perform in conformity with the description contained in the instructions provided. This machine must be checked periodically. Defective equipment (including power cables) should not be used. Parts that are broken, missing, plainly worn, distorted or contaminated, should be replaced immediately. Should such repair or replacement become necessary, it is recommended that such repairs are carried out by qualified persons approved by metabo or its representatives.