turning blades. If clutch does not slip, contact your authorized Bush Hog dealer.

C. Retighten nuts to within 1/64” of original posi- tion. Initial spring length is shown in Figure

![]() WARNING

WARNING

OVERTIGHTENING SPRING NUTS MAY

CAUSE DAMAGE TO IMPLEMENT AND/OR

TRACTOR DUE TO INCORRECT SLIP CLUTCH

TORQUE SETTING. ALWAYS FOLLOW THE

PROPER ADJUSTMENT PROCEDURE.

4-6 SLIP CLUTCH ADJUSTMENT

The slip clutch is factory preset to the correct torque

for protecting implement and tractor. | Periodic | |

adjustment is recommended | ; refer to section | |

Should adjustment be needed, first check to be sure |

| |

all spring lengths are the | same. Initial spring length | |

is shown in Figure | necessary, adjust nut | on |

any spring that is unequal. Adjust all eight spring | ||

retaining nuts 1/3 of a turn (2 flats on a nut) and | ||

check clutch slippage. If further adjustment is neces- | ||

sary, do so in 1/3 turn | increments. | Adjust only to |

provide sufficient torque to prevent slippage under | ||

normal conditions. Occasional slippage is normal |

| |

for drivetrain protection | . If satisfactory results cannot | |

be obtained, consult your Bush Hog dealer.

IMPORTANT

Do not overtighten nut and cause spring to become solid as this will cause shaft to fail.

|

| |

Figure |

| |

| 32.2 mm | |

Spring Length |

| |

|

| |

|

|

|

|

|

|

| (Figure |

OIL LEVEL - The gearbox assembly on the 305/306 rotary cutters are shipped from the factory less oil. Use

OIL SEAL LEAKAGE - The three main causes of oil seal failure are as follows:

1.Operating cutter for any length of time with wire or litter wrapped around the upper or lower shaft.

2.Loose bearings.

3.Worn seals. Leaky seals should be replaced as soon as possible.

SEAL REPLACEMENT - To replace the seals on your cutter, follow the steps outlined below:

1.Remove the blade holder and universal joint.

2.Knock out old seals.

3.Install new seals.

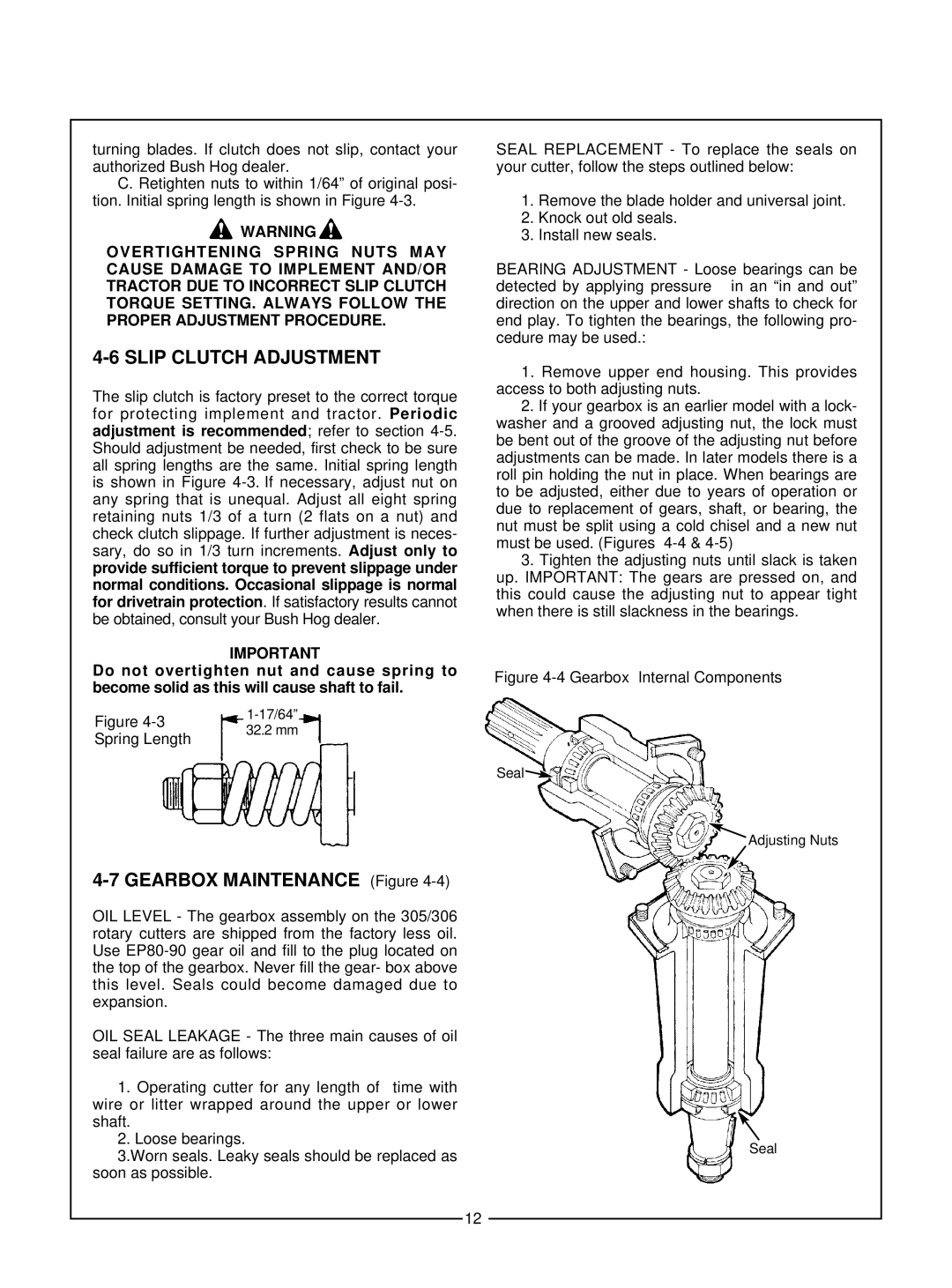

BEARING ADJUSTMENT - Loose bearings can be

detected by applying pressurein an “in and out” direction on the upper and lower shafts to check for

end play. To tighten the bearings, the following pro- cedure may be used.:

1.Remove upper end housing. This provides access to both adjusting nuts.

2.If your gearbox is an earlier model with a lock- washer and a grooved adjusting nut, the lock must

be bent out of the groove of the adjusting nut before adjustments can be made. In later models there is a roll pin holding the nut in place. When bearings are to be adjusted, either due to years of operation or due to replacement of gears, shaft, or bearing, the nut must be split using a cold chisel and a new nut must be used. (Figures

3.Tighten the adjusting nuts until slack is taken up. IMPORTANT: The gears are pressed on, and this could cause the adjusting nut to appear tight when there is still slackness in the bearings.

Figure 4-4 Gearbox Internal Components

Seal

![]() Adjusting Nuts

Adjusting Nuts

Seal

12