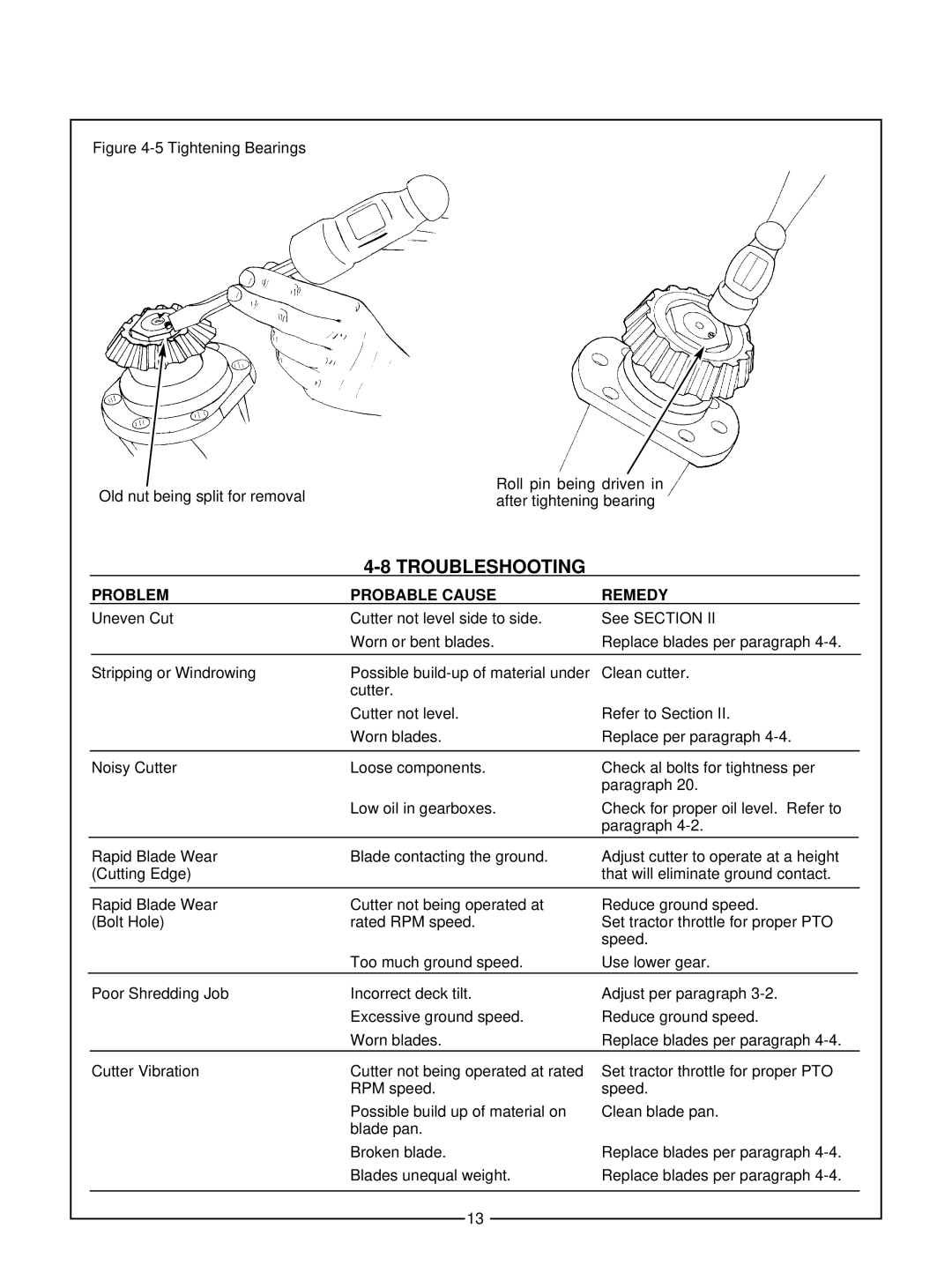

Figure 4-5 Tightening Bearings

| Old nut being split for removal |

|

| Roll pin being driven in |

|

|

|

| after tightening bearing |

| |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

4-8 TROUBLESHOOTING

| PROBLEM | PROBABLE CAUSE | REMEDY |

|

|

| Uneven Cut | Cutter not level side to side. | See SECTION II | ||

|

| Worn or bent blades. |

| Replace blades per paragraph | |

|

|

|

|

| |

| Stripping or Windrowing | Possible | Clean cutter. | ||

|

| cutter. |

|

|

|

|

| Cutter not level. |

| Refer to Section II. | |

|

| Worn blades. |

| Replace per paragraph | |

|

|

|

|

|

|

| Noisy Cutter | Loose components. |

| Check al bolts for tightness per | |

|

|

|

| paragraph 20. | |

|

| Low oil in gearboxes. |

| Check for proper oil level. Refer to | |

|

|

|

| paragraph | |

|

|

|

|

| |

| Rapid Blade Wear | Blade contacting the ground. | Adjust cutter to operate at a height | ||

| (Cutting Edge) |

|

| that will eliminate ground contact. | |

|

|

|

|

| |

| Rapid Blade Wear | Cutter not being operated at | Reduce ground speed. | ||

| (Bolt Hole) | rated RPM speed. |

| Set tractor throttle for proper PTO | |

|

|

|

| speed. | |

|

| Too much ground speed. |

| Use lower gear. | |

|

|

|

|

|

|

| Poor Shredding Job | Incorrect deck tilt. |

| Adjust per paragraph | |

|

| Excessive ground speed. |

| Reduce ground speed. | |

|

| Worn blades. |

| Replace blades per paragraph | |

| Cutter Vibration | Cutter not being operated at rated | Set tractor throttle for proper PTO | ||

|

| RPM speed. |

| speed. | |

|

| Possible build up of material on | Clean blade pan. | ||

|

| blade pan. |

|

|

|

|

| Broken blade. |

| Replace blades per paragraph | |

|

| Blades unequal weight. |

| Replace blades per paragraph | |

|

|

|

|

|

|

13