ASSEMBLY (Refer to Figures 13 & 14)

IMPORTANT: Tighten all hardware to the torque requirements specified in the torque chart.

![]() WARNING

WARNING ![]()

To prevent bodily injury, do not operate backhoe unless Lower Link Weldments (1, 2) are properly installed and adjusted. Failure to do so may result in backhoe being thrust upward, crushing operator against cab or ROPS.

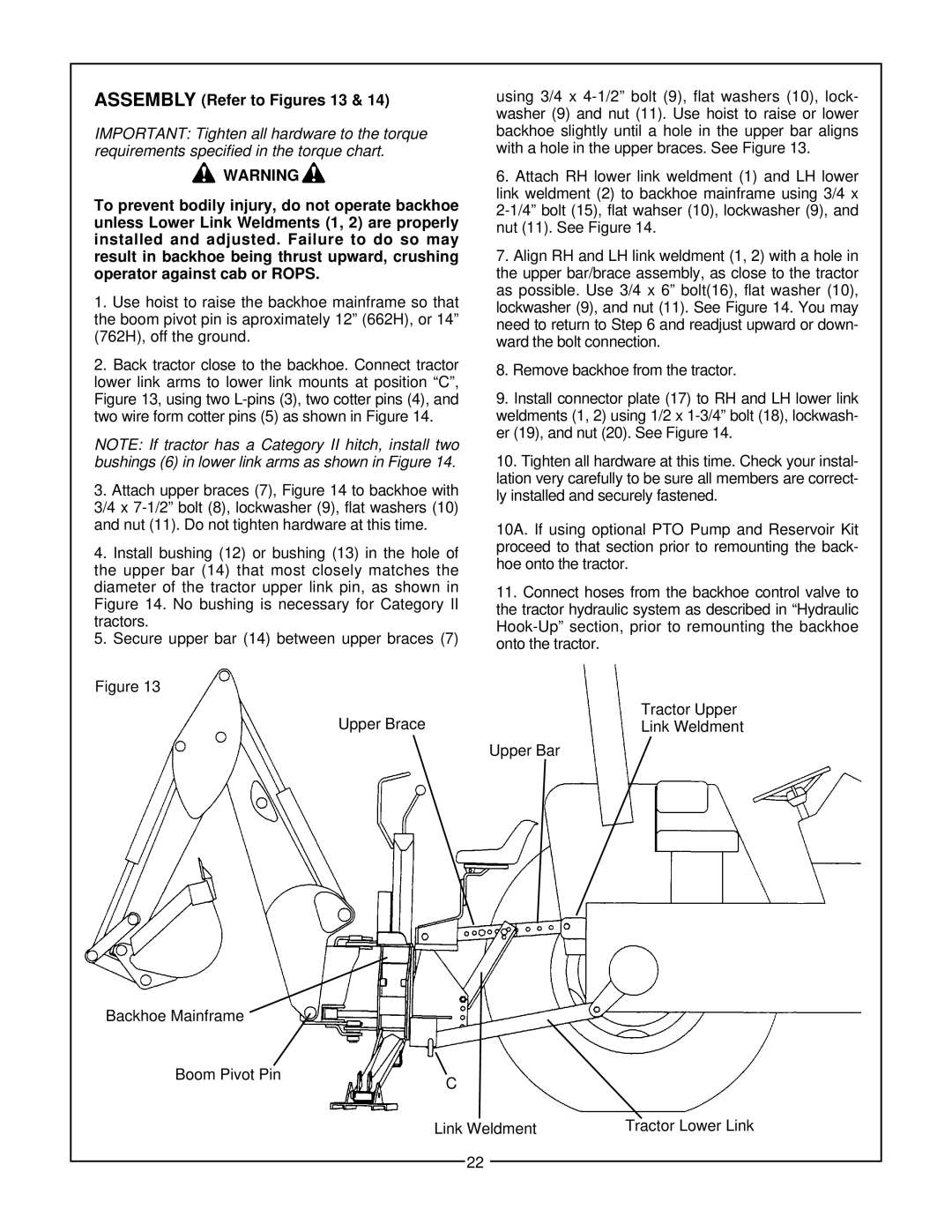

1.Use hoist to raise the backhoe mainframe so that the boom pivot pin is aproximately 12” (662H), or 14” (762H), off the ground.

2.Back tractor close to the backhoe. Connect tractor lower link arms to lower link mounts at position “C”, Figure 13, using two

NOTE: If tractor has a Category II hitch, install two bushings (6) in lower link arms as shown in Figure 14.

3.Attach upper braces (7), Figure 14 to backhoe with 3/4 x

4.Install bushing (12) or bushing (13) in the hole of the upper bar (14) that most closely matches the diameter of the tractor upper link pin, as shown in Figure 14. No bushing is necessary for Category II tractors.

5.Secure upper bar (14) between upper braces (7)

Figure 13

Upper Brace

using 3/4 x

6.Attach RH lower link weldment (1) and LH lower link weldment (2) to backhoe mainframe using 3/4 x

7.Align RH and LH link weldment (1, 2) with a hole in the upper bar/brace assembly, as close to the tractor as possible. Use 3/4 x 6” bolt(16), flat washer (10), lockwasher (9), and nut (11). See Figure 14. You may need to return to Step 6 and readjust upward or down- ward the bolt connection.

8.Remove backhoe from the tractor.

9.Install connector plate (17) to RH and LH lower link weldments (1, 2) using 1/2 x

10.Tighten all hardware at this time. Check your instal- lation very carefully to be sure all members are correct- ly installed and securely fastened.

10A. If using optional PTO Pump and Reservoir Kit proceed to that section prior to remounting the back- hoe onto the tractor.

11.Connect hoses from the backhoe control valve to the tractor hydraulic system as described in “Hydraulic

Tractor Upper

Link Weldment

Upper Bar

Backhoe Mainframe

Boom Pivot Pin

C

Link Weldment |

| Tractor Lower Link |

|

|

|

22