SECTION II

PREPARATION FOR USE

2-1 ATTACHING TO TRACTOR

![]() WARNING

WARNING ![]()

NEVER STAND BETWEEN TRACTOR AND CUTTER WHILE TRACTOR IS BEING BACKED TO HITCH.

![]() WARNING

WARNING ![]()

ADDITIONAL TRACTOR FRONT BALLAST MAY BE NEEDED FOR STABLE OPERATION AND TRANSPORT OF CUTTER. SEE TRACTOR OPERA- TOR’S MANUAL FOR RECOMMENDED WEIGHTS. IT IS RECOMMENDED THAT TRACTOR BE EQUIPPED WITH ROLLOVER PROTECTIVE SYSTEM (ROPS) AND SEAT BELTS.

A. Attach to tractor Cat. I three point hitch as described in tractor operator’s manual.

NOTE

Due to the many variations in tractor/implement hitch points and corre- sponding differences in distances between tractor PTO shafts and implement input shafts, drivelines may need to be short- ened as described in the following steps:

B. Raise and lower cutter to determine position with shortest distance between the tractor PTO shaft and gearbox input shaft. Shut down tractor leaving cutter in position of shortest distance.

SECURELY BLOCK CUTTER IN POSITION.

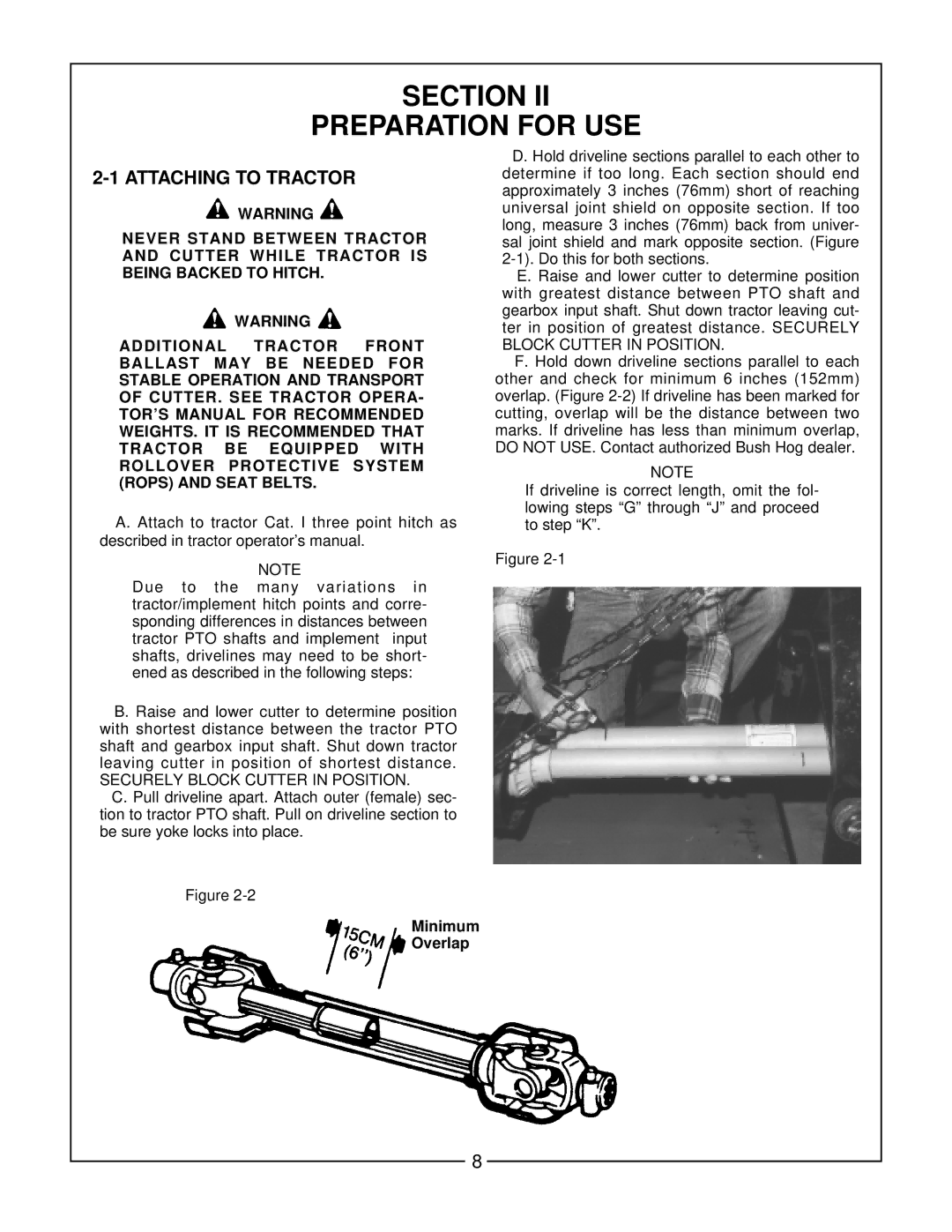

C. Pull driveline apart. Attach outer (female) sec- tion to tractor PTO shaft. Pull on driveline section to be sure yoke locks into place.

Figure

Minimum

Overlap

D. Hold driveline sections parallel to each other to determine if too long. Each section should end approximately 3 inches (76mm) short of reaching universal joint shield on opposite section. If too long, measure 3 inches (76mm) back from univer- sal joint shield and mark opposite section. (Figure

E. Raise and lower cutter to determine position with greatest distance between PTO shaft and gearbox input shaft. Shut down tractor leaving cut- ter in position of greatest distance. SECURELY BLOCK CUTTER IN POSITION.

F. Hold down driveline sections parallel to each other and check for minimum 6 inches (152mm) overlap. (Figure

NOTE

If driveline is correct length, omit the fol- lowing steps “G” through “J” and proceed to step “K”.

Figure

8