SECTION II

PREPARATION FOR USE

|

|

|

|

| Due to the many variations in trac- | |||

|

|

|

|

|

|

|

| NOTE |

|

|

| WARNING |

|

|

|

| tor/implement hitch points and corre- |

| NEVER STAND BETWEEN TRACTOR |

|

| sponding differences in distances between | ||||

|

|

| tractor PTO shafts and implement input | |||||

| AND CUTTER WHILE TRACTOR IS |

|

| shafts, drivelines may need to be short- | ||||

| BEING BACKED TO HITCH. |

|

|

|

| ened as described in the following steps: | ||

|

|

| WARNING |

|

|

| B. | Raise and lower cutter to determine position |

ADDITIONAL | TRACTOR | FRONT |

| with shortest distance between the tractor PTO shaft | ||||

BALLAST MAY BE NEEDED FOR |

| and gearbox input shaft. Shut down tractor leaving | ||||||

STABLE OPERATION AND TRANSPORT |

| cutter in position of shortest distance. SECURELY | ||||||

OF CUTTER. SEE TRACTOR OPERA- |

| |||||||

TOR’S MANUAL FOR RECOMMENDED |

| BLOCK CUTTER IN POSITION. | ||||||

WEIGHTS. IT IS RECOMMENDED THAT |

| C. Pull driveline apart. Attach outer (female) sec- | ||||||

TRACTOR | BE | EQUIPPED | WITH |

| tion to tractor PTO shaft. Pull on driveline section to | |||

ROLLOVER | PROTECTIVE SYSTEM |

| be sure yoke locks into place. | |||||

(ROPS) AND SEAT BELTS. |

|

|

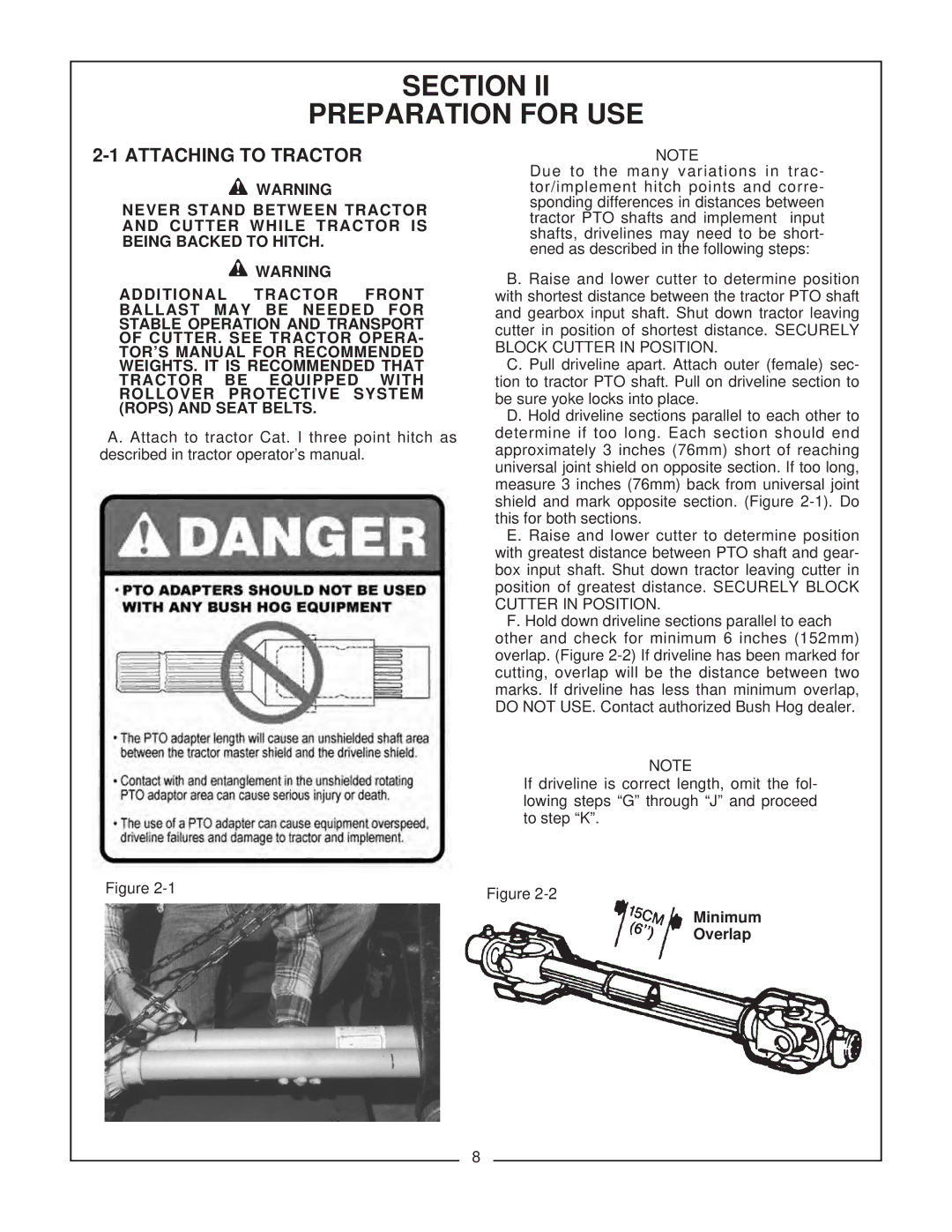

| D. Hold driveline sections parallel to each other to | ||||

A. Attach to tractor Cat. I three point hitch | as | determine if too long. Each section should end | ||||||

described in tractor operator’s manual. |

|

|

| approximately 3 inches (76mm) short of reaching | ||||

|

|

| universal joint shield on opposite section. If too long, | |||||

|

|

|

|

|

|

| measure 3 inches (76mm) back from universal joint | |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| shield and mark opposite section. (Figure | |

|

|

|

|

|

|

| this for both sections. | |

|

|

|

|

|

|

| E. Raise and lower cutter to determine position | |

|

|

|

|

|

|

| with greatest distance between PTO shaft and gear- | |

|

|

|

|

|

|

| box input shaft. Shut down tractor leaving cutter in | |

|

|

|

|

|

|

| position of greatest distance. SECURELY BLOCK | |

|

|

|

|

|

|

| CUTTER IN POSITION. | |

|

|

|

|

|

|

| F. Hold down driveline sections parallel to each | |

|

|

|

|

|

|

| other and check for minimum 6 inches (152mm) | |

|

|

|

|

|

|

| overlap. (Figure | |

|

|

|

|

|

|

| cutting, overlap will be the distance between two | |

|

|

|

|

|

|

| marks. If driveline has less than minimum overlap, | |

|

|

|

|

|

|

| DO NOT USE. Contact authorized Bush Hog dealer. | |

|

|

|

|

|

|

|

| NOTE |

|

|

|

|

|

|

| If driveline is correct length, omit the fol- | |

|

|

|

|

|

|

| lowing steps “G” through “J” and proceed | |

|

|

|

|

|

|

| to step “K”. | |

Figure | Figure | Minimum |

| ||

|

| |

|

| Overlap |

8