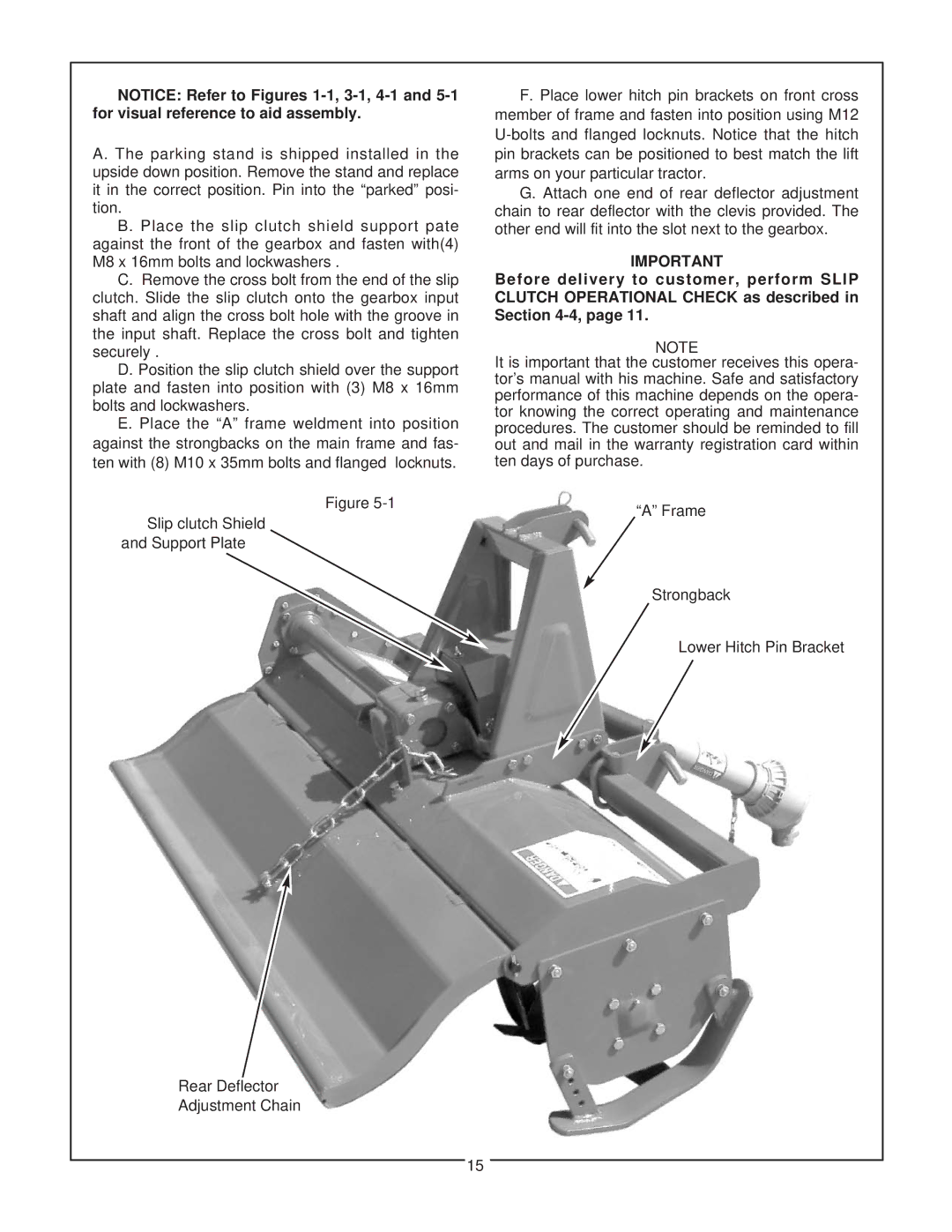

NOTICE: Refer to Figures

A. The parking stand is shipped installed in the upside down position. Remove the stand and replace it in the correct position. Pin into the “parked” posi- tion.

B. Place the slip clutch shield support pate against the front of the gearbox and fasten with(4) M8 x 16mm bolts and lockwashers .

C.Remove the cross bolt from the end of the slip clutch. Slide the slip clutch onto the gearbox input shaft and align the cross bolt hole with the groove in the input shaft. Replace the cross bolt and tighten securely .

D.Position the slip clutch shield over the support plate and fasten into position with (3) M8 x 16mm bolts and lockwashers.

E.Place the “A” frame weldment into position against the strongbacks on the main frame and fas- ten with (8) M10 x 35mm bolts and flanged locknuts.

Figure

Slip clutch Shield and Support Plate

Rear Deflector

Adjustment Chain

F. Place lower hitch pin brackets on front cross member of frame and fasten into position using M12

G. Attach one end of rear deflector adjustment chain to rear deflector with the clevis provided. The other end will fit into the slot next to the gearbox.

IMPORTANT

Before delivery to customer, perform SLIP CLUTCH OPERATIONAL CHECK as described in Section

NOTE

It is important that the customer receives this opera- tor’s manual with his machine. Safe and satisfactory performance of this machine depends on the opera- tor knowing the correct operating and maintenance procedures. The customer should be reminded to fill out and mail in the warranty registration card within ten days of purchase.

“A” Frame

Strongback

Lower Hitch Pin Bracket

15