BEEF: Choose Flank, Round or Sirloin Tip cuts, as they are the best beef cuts for making jerky.

WILD GAME: Venison makes excellent jerky because it does not contain marbleized fat. Flank or Round Cuts work best. Bear and Elk meat also make very good jerky.

POULTRY: Whether making chicken or turkey jerky, it is important that the meat be cooked heated to an internal temperature of 165oF (74oC) before dehydrating to kill

FISH: Drying fish into jerky requires a lot of attention. It must be cleaned and de- boned properly and rinsed thoroughly to ensure that all the blood is washed away. Steam or bake the fish at 200oF (93oC) until flaky before dehydrating.

MAKING JERKY

Meat should be as lean as possible. Using lean meat will help the meat dry faster and aid in cleanup by decreasing fat drippings. Ground meat should be 80% to 90% lean. Ground turkey, venison, buffalo and elk are other excellent choices for Jerky.

Jerky seasonings are available for all tastes, or you can get creative and make your own. Whenever you make Jerky, you should cure the mixture with cure (sodium nitrite). The cure is used to help prevent botulism during drying at low temperatures. Follow the manufacturer’s directions on the cure packet.

Keep raw meats and their juices away from other foods. Marinate meats in the refrigerator. Do not leave meats unrefrigerated. Prevent

Keep meat and poultry refrigerated at 40°F (4.4°C) or slightly below; use or freeze ground beef and poultry within 2 days; whole red meats, within 3 to 5 days. Defrost frozen meat in the refrigerator, not on the kitchen counter.

Special considerations must be made when using venison or other wild game, since it can become heavily contaminated during field dressing. Venison is often held at temperatures that could potentially allow bacteria to grow, such as when it is being transported. Refer to the USDA website for further information on food safety. (www. usda.gov or www.fsis.usda.gov/fact_sheets/index.asp)

When using a Dehydrator, check the temperature of the Dehydrator with a dial thermometer before drying jerky. The minimum recommended temperature for drying meats is 130°F (54°C). Temperatures below 130°F (54°C) are not recommended. IMPORTANT: Before placing the meat in a Dehydrator, it is highly recommended to heat the meat to 160°F (71°C) BEFORE the dehydrating process. This step assures that any bacteria present will be destroyed by wet heat. After heating to 160°F (71°C), maintaining a constant Dehydrator temperature of

1.) the process must be fast enough to dry food before it spoils; and

2.) it must remove enough water so that microorganisms are unable to grow.

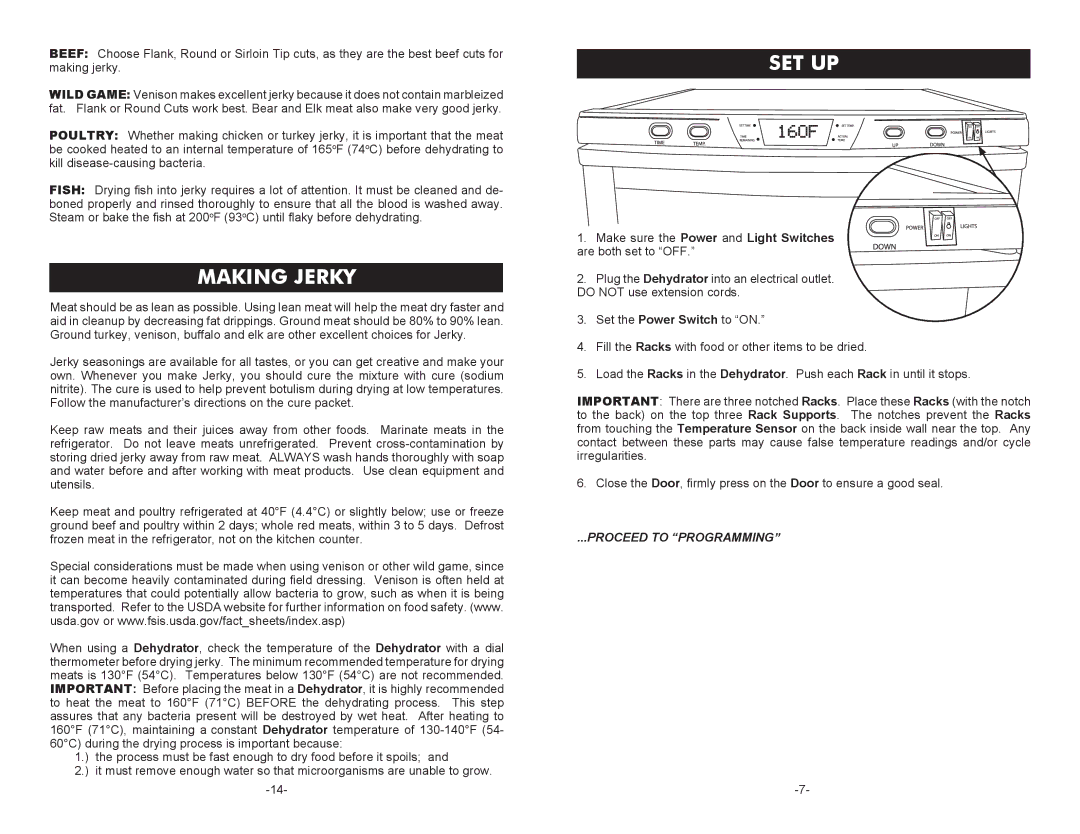

SET UP

1. Make sure the Power and Light Switches are both set to “OFF.”

2.Plug the Dehydrator into an electrical outlet. DO NOT use extension cords.

3.Set the Power Switch to “ON.”

4.Fill the Racks with food or other items to be dried.

5.Load the Racks in the Dehydrator. Push each Rack in until it stops.

IMPORTANT: There are three notched Racks. Place these Racks (with the notch to the back) on the top three Rack Supports. The notches prevent the Racks from touching the Temperature Sensor on the back inside wall near the top. Any contact between these parts may cause false temperature readings and/or cycle irregularities.

6. Close the Door, firmly press on the Door to ensure a good seal.

...PROCEED TO “PROGRAMMING”