To

Tighten  Wrench

Wrench

To

LoosenClamp

Nut

Nut

Grinding wheel

Disc

Flange

SpindleGuard

Figure 2

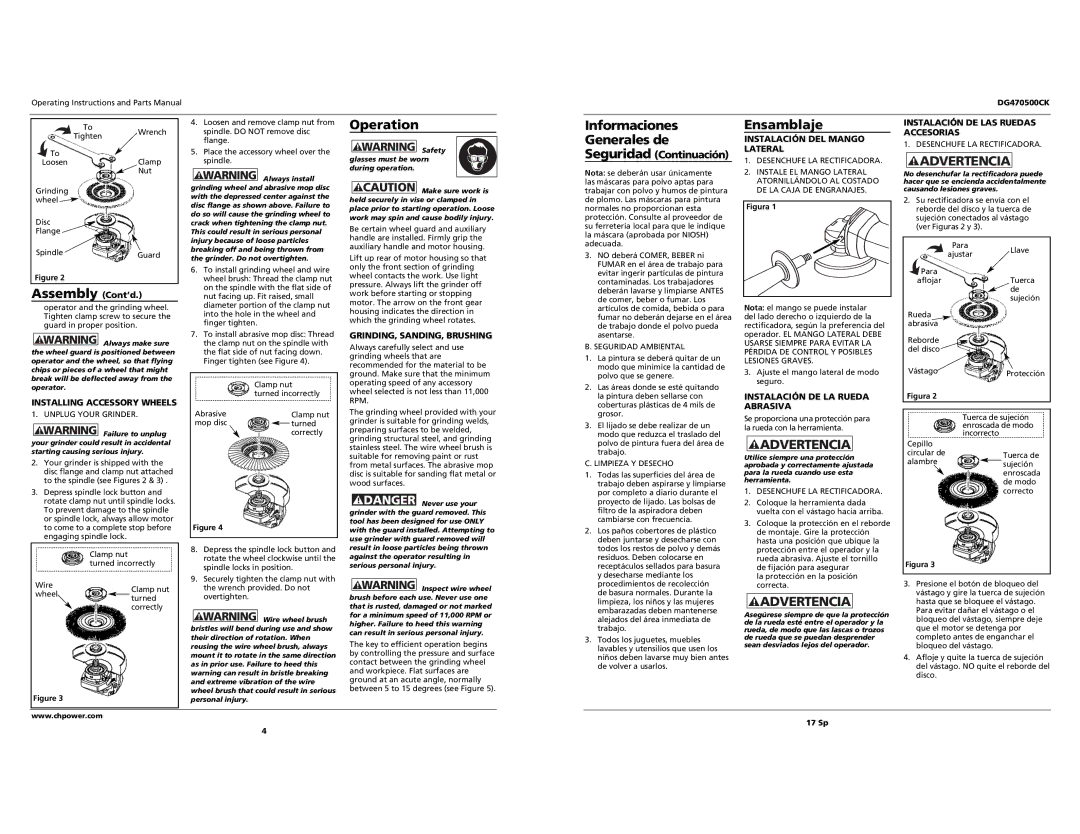

Assembly (Cont’d.)

operator and the grinding wheel. Tighten clamp screw to secure the guard in proper position.

!WARNING Always make sure the wheel guard is positioned between operator and the wheel, so that flying chips or pieces of a wheel that might break will be deflected away from the operator.

INSTALLING ACCESSORY WHEELS

1.UNPLUG YOUR GRINDER.

!WARNING Failure to unplug your grinder could result in accidental starting causing serious injury.

2.Your grinder is shipped with the disc flange and clamp nut attached to the spindle (see Figures 2 & 3) .

3.Depress spindle lock button and rotate clamp nut until spindle locks. To prevent damage to the spindle or spindle lock, always allow motor to come to a complete stop before engaging spindle lock.

Clamp nut turned incorrectly

Wire | | Clamp nut |

wheel | |

| turned |

| |

| | correctly |

Figure 3

4.Loosen and remove clamp nut from spindle. DO NOT remove disc flange.

5.Place the accessory wheel over the spindle.

!WARNING Always install grinding wheel and abrasive mop disc with the depressed center against the disc flange as shown above. Failure to do so will cause the grinding wheel to crack when tightening the clamp nut. This could result in serious personal injury because of loose particles breaking off and being thrown from the grinder. Do not overtighten.

6.To install grinding wheel and wire wheel brush: Thread the clamp nut on the spindle with the flat side of nut facing up. Fit raised, small diameter portion of the clamp nut into the hole in the wheel and finger tighten.

7.To install abrasive mop disc: Thread the clamp nut on the spindle with the flat side of nut facing down. Finger tighten (see Figure 4).

| Clamp nut |

| turned incorrectly |

Abrasive | | | Clamp nut |

mop disc | | | turned |

| |

| | | correctly |

Figure 4

8.Depress the spindle lock button and rotate the wheel clockwise until the spindle locks in position.

9.Securely tighten the clamp nut with the wrench provided. Do not overtighten.

!WARNING Wire wheel brush bristles will bend during use and show their direction of rotation. When reusing the wire wheel brush, always mount it to rotate in the same direction as in prior use. Failure to heed this warning can result in bristle breaking and extreme vibration of the wire wheel brush that could result in serious personal injury.

Operation

! WARNING Safety

glasses must be worn during operation.

!CAUTION Make sure work is held securely in vise or clamped in place prior to starting operation. Loose work may spin and cause bodily injury.

Be certain wheel guard and auxiliary handle are installed. Firmly grip the auxiliary handle and motor housing.

Lift up rear of motor housing so that only the front section of grinding wheel contacts the work. Use light pressure. Always lift the grinder off work before starting or stopping motor. The arrow on the front gear housing indicates the direction in which the grinding wheel rotates.

GRINDING, SANDING, BRUSHING

Always carefully select and use grinding wheels that are recommended for the material to be ground. Make sure that the minimum operating speed of any accessory wheel selected is not less than 11,000 RPM.

The grinding wheel provided with your grinder is suitable for grinding welds, preparing surfaces to be welded, grinding structural steel, and grinding stainless steel. The wire wheel brush is suitable for removing paint or rust from metal surfaces. The abrasive mop disc is suitable for sanding flat metal or wood surfaces.

!DANGER Never use your grinder with the guard removed. This tool has been designed for use ONLY with the guard installed. Attempting to use grinder with guard removed will result in loose particles being thrown against the operator resulting in serious personal injury.

!WARNING Inspect wire wheel brush before each use. Never use one that is rusted, damaged or not marked for a minimum speed of 11,000 RPM or higher. Failure to heed this warning can result in serious personal injury.

The key to efficient operation begins by controlling the pressure and surface contact between the grinding wheel and workpiece. Flat surfaces are ground at an acute angle, normally between 5 to 15 degrees (see Figure 5).

Informaciones Generales de Seguridad (Continuación)

Nota: se deberán usar únicamente las máscaras para polvo aptas para trabajar con polvo y humos de pintura de plomo. Las máscaras para pintura normales no proporcionan esta protección. Consulte al proveedor de su ferretería local para que le indique la máscara (aprobada por NIOSH) adecuada.

3.NO deberá COMER, BEBER ni FUMAR en el área de trabajo para evitar ingerir partículas de pintura contaminadas. Los trabajadores deberán lavarse y limpiarse ANTES de comer, beber o fumar. Los artículos de comida, bebida o para fumar no deberán dejarse en el área de trabajo donde el polvo pueda asentarse.

B. SEGURIDAD AMBIENTAL

1.La pintura se deberá quitar de un modo que minimice la cantidad de polvo que se genere.

2.Las áreas donde se esté quitando la pintura deben sellarse con coberturas plásticas de 4 mils de grosor.

3.El lijado se debe realizar de un modo que reduzca el traslado del polvo de pintura fuera del área de trabajo.

C. LIMPIEZA Y DESECHO

1.Todas las superficies del área de trabajo deben aspirarse y limpiarse por completo a diario durante el proyecto de lijado. Las bolsas de filtro de la aspiradora deben cambiarse con frecuencia.

2.Los paños cobertores de plástico deben juntarse y desecharse con todos los restos de polvo y demás residuos. Deben colocarse en receptáculos sellados para basura y desecharse mediante los procedimientos de recolección de basura normales. Durante la limpieza, los niños y las mujeres embarazadas deben mantenerse alejados del área inmediata de trabajo.

3.Todos los juguetes, muebles lavables y utensilios que usen los niños deben lavarse muy bien antes de volver a usarlos.

Ensamblaje

INSTALACIÓN DEL MANGO LATERAL

1.DESENCHUFE LA RECTIFICADORA.

2.INSTALE EL MANGO LATERAL ATORNILLÁNDOLO AL COSTADO DE LA CAJA DE ENGRANAJES.

Nota: el mango se puede instalar del lado derecho o izquierdo de la rectificadora, según la preferencia del operador. EL MANGO LATERAL DEBE USARSE SIEMPRE PARA EVITAR LA PÉRDIDA DE CONTROL Y POSIBLES LESIONES GRAVES.

3.Ajuste el mango lateral de modo seguro.

INSTALACIÓN DE LA RUEDA ABRASIVA

Se proporciona una protección para la rueda con la herramienta.

!ADVERTENCIA

Utilice siempre una protección aprobada y correctamente ajustada para la rueda cuando use esta herramienta.

1.DESENCHUFE LA RECTIFICADORA.

2.Coloque la herramienta dada vuelta con el vástago hacia arriba.

3.Coloque la protección en el reborde de montaje. Gire la protección hasta una posición que ubique la protección entre el operador y la rueda abrasiva. Ajuste el tornillo de fijación para asegurar

la protección en la posición correcta.

!ADVERTENCIA

Asegúrese siempre de que la protección de la rueda esté entre el operador y la rueda, de modo que las lascas o trozos de rueda que se puedan desprender sean desviados lejos del operador.

INSTALACIÓN DE LAS RUEDAS ACCESORIAS

1. DESENCHUFE LA RECTIFICADORA.

!ADVERTENCIA

No desenchufar la rectificadora puede hacer que se encienda accidentalmente causando lesiones graves.

2.Su rectificadora se envía con el reborde del disco y la tuerca de sujeción conectados al vástago (ver Figuras 2 y 3).

Para

ajustar  Llave

Llave

Para

aflojarTuerca  de sujeción

de sujeción

Rueda abrasiva

Reborde del disco

VástagoProtección

Figura 2

Tuerca de sujeción enroscada de modo incorrecto

Cepillo | | |

circular de | | Tuerca de |

alambre | |

| sujeción |

| |

| | enroscada |

| | de modo |

| | correcto |

Figura 3

3.Presione el botón de bloqueo del vástago y gire la tuerca de sujeción hasta que se bloquee el vástago. Para evitar dañar el vástago o el bloqueo del vástago, siempre deje que el motor se detenga por completo antes de enganchar el bloqueo del vástago.

4.Afloje y quite la tuerca de sujeción del vástago. NO quite el reborde del disco.