Pistola Pulverización de Uso General

Model KBS530

LIMPIEZA PERIODICA

De vez en cuando deberá inspeccionar y limpiar el interior y exterior de la pistola para quitarle los residuos de pintura y acumulaciones de polvo.

1.Examine los orificios de la tapa de aire y la boquilla. Si están obstruídos, quítele los anillos en O y sumerja la tapa de aire o la boquilla en solvente.

2.Puede utilizar un cepillo, palillo u otro objeto similar para sacar la pintura seca de los orificios o ductos.

NUNCA USE OBJETOS DE METAL PARA LIMPIAR DUCTOS TALADRADOS A PRESICION. SI ESTOS SE DAÑAN PODRIA AFECTAR EL ROCIO.

3.Desconecte y revise la aguja de ajuste para ver si está muy desgastada o torcida.

IMPORTANTE: Si el extremo de la aguja está más desgastado en un lado, la aguja está torcida o la pistola está desalineada debido a un golpe o una caida. Si la pistola está torcida no podrá repararla. Para probar la aguja, deslicéla sobre una superficie plana. Reemplácela si es necesario.

4.Chequée y reemplace los anillos y sellos dañados. Éstos se pueden limpiar pero no los debe sumerjir en solvente.

5.Sáquele las tuercas que sostienen los empaques y reemplácelos SOLO si no puede eliminar la fuga de material después de apretar las tuercas. No apriete demasiado estas tuercas ya que podría restringir el movimiento de la aguja.

6.Ensamble las piezas en orden contrario a lo anterior y use aceite sin silicón en las piezas movibles. Aplíquele Vaselina o grasa liviana a las conexiones con roscas y a las de las mangueras.

PARA ALMACENAR

1.Cuando no vaya a usar la pistola pulverizadora, gire la perilla de control de fluído en sentido contrario a las agujas del reloj para reducir la tensión del resorte sobre la aguja.

2.La pistola pulverizadora DEBE estar bien limpia y ligeramente lubricada.

USING A PRESSURIZED PAINT TANK

The spray gun in this manual is readily adaptable for use with a pressurized paint tank. This allows continuous spraying of large quantities of paint without stopping. It also allows the gun to be used while being held in ANY position without spilling paint.

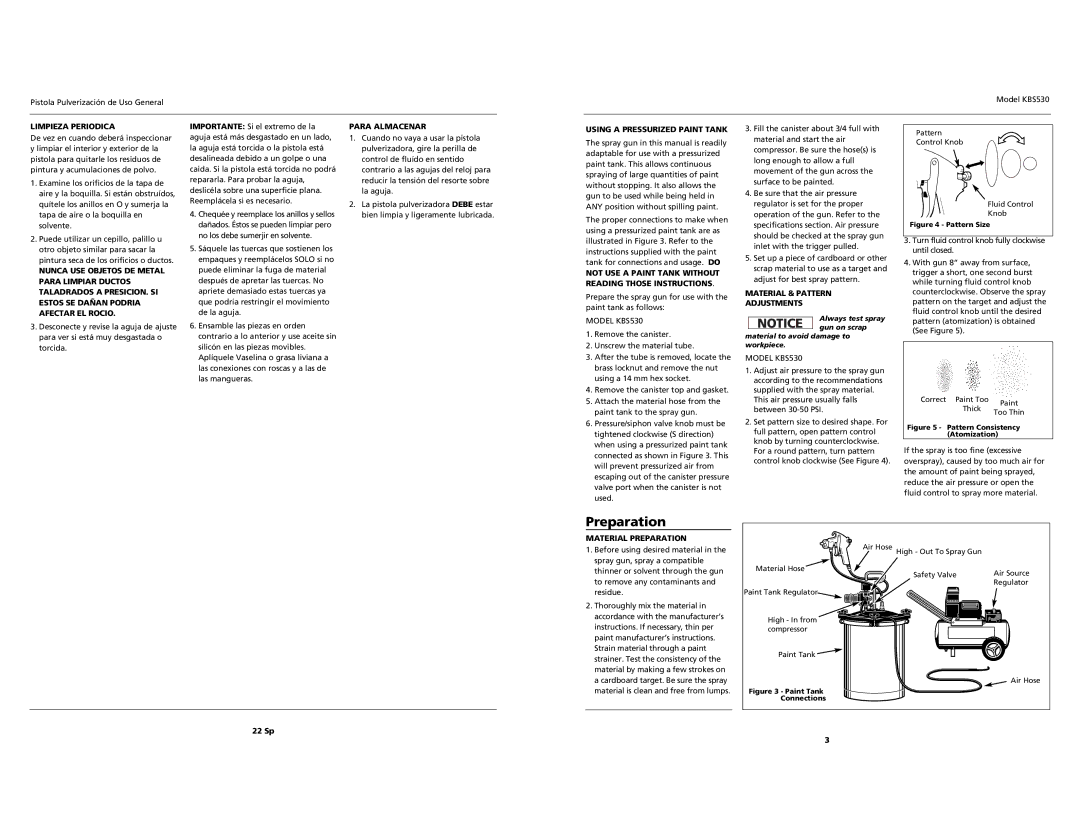

The proper connections to make when using a pressurized paint tank are as illustrated in Figure 3. Refer to the instructions supplied with the paint tank for connections and usage. DO

NOT USE A PAINT TANK WITHOUT READING THOSE INSTRUCTIONS.

Prepare the spray gun for use with the paint tank as follows:

MODEL KBS530

1.Remove the canister.

2.Unscrew the material tube.

3.After the tube is removed, locate the brass locknut and remove the nut using a 14 mm hex socket.

4.Remove the canister top and gasket.

5.Attach the material hose from the paint tank to the spray gun.

6.Pressure/siphon valve knob must be tightened clockwise (S direction) when using a pressurized paint tank connected as shown in Figure 3. This will prevent pressurized air from escaping out of the canister pressure valve port when the canister is not used.

3.Fill the canister about 3/4 full with material and start the air compressor. Be sure the hose(s) is long enough to allow a full movement of the gun across the surface to be painted.

4.Be sure that the air pressure regulator is set for the proper operation of the gun. Refer to the specifications section. Air pressure should be checked at the spray gun inlet with the trigger pulled.

5.Set up a piece of cardboard or other scrap material to use as a target and adjust for best spray pattern.

MATERIAL & PATTERN

ADJUSTMENTS

NOTICE | Always test spray |

gun on scrap |

material to avoid damage to workpiece.

MODEL KBS530

1.Adjust air pressure to the spray gun according to the recommendations supplied with the spray material.

This air pressure usually falls between

2.Set pattern size to desired shape. For full pattern, open pattern control knob by turning counterclockwise. For a round pattern, turn pattern control knob clockwise (See Figure 4).

Pattern

Control Knob

Fluid Control

Knob

Figure 4 - Pattern Size

3.Turn fluid control knob fully clockwise until closed.

4.With gun 8” away from surface, trigger a short, one second burst while turning fluid control knob counterclockwise. Observe the spray pattern on the target and adjust the fluid control knob until the desired pattern (atomization) is obtained (See Figure 5).

Correct Paint Too | Paint | |

Thick | ||

Too Thin | ||

|

Figure 5 - Pattern Consistency (Atomization)

If the spray is too fine (excessive overspray), caused by too much air for the amount of paint being sprayed, reduce the air pressure or open the fluid control to spray more material.

Preparation

MATERIAL PREPARATION

1.Before using desired material in the spray gun, spray a compatible thinner or solvent through the gun to remove any contaminants and residue.

2.Thoroughly mix the material in accordance with the manufacturer’s instructions. If necessary, thin per paint manufacturer’s instructions. Strain material through a paint strainer. Test the consistency of the material by making a few strokes on a cardboard target. Be sure the spray material is clean and free from lumps.

Material Hose

Paint Tank Regulator

High - In from compressor

Paint Tank![]()

Figure 3 - Paint Tank

Connections

Air Hose High - Out To Spray Gun |

|

Safety Valve | Air Source |

| Regulator |

Air Hose

22 Sp

3