General Purpose Spray Guns

Modelo KBS530

Model Descriptions (Cont.)

•Adjusts for vertical or horizontal patterns.

•May be used with a paint tank.

General Safety

1. Read all manuals |

|

|

|

|

|

| |

included with this |

|

|

|

product carefully. Be |

| MANUAL |

|

thoroughly familiar |

|

|

|

|

| ||

with the controls and |

|

|

|

|

|

|

the proper use of the equipment.

2.Follow all local electrical and safety codes as well as in the United States, the National Electrical Codes (NEC), Occupational Safety and Health Act (OSHA) and the Environmental Protection Agency (EPA).

! WARNING

Safety glasses and ear protection must be worn during operation.

!WARNING

Use a face mask/respirator and protective clothing when spraying. Always spray in a well ventilated area to prevent health and fire hazards. Refer to Material Safety Data Sheets (MSDS) of spray material for details.

! DANGER

Never spray closer than 25 feet to the compressor! If possible, locate compressor in separate room. Never spray into the compressor, compressor controls or the motor.

3.Do not smoke or eat when spraying paint, insecticides, or other flammable substances.

!WARNING

Do not spray flammable materials in vicinity of open flame or near ignition sources. Motors, electrical equipment and controls can cause electrical arcs that will ignite a flammable gas or vapor. Never store flammable liquids or gases in the vicinity of the compressor.

4.When spraying and cleaning, always follow the instructions and safety precautions provided by the material manufacturer (Refer to MSDS).

! WARNING Do

not spray acids, corrosive materials, toxic chemicals, fertilizers or pesticides.

Using these materials could result in death or serious injury.

5.Keep visitors away and NEVER allow children or pets in the work area.

! WARNING | Never aim or |

spray at yourself |

or anyone else or serious injury could occur.

6.Always work in a clean environment. To avoid injury and damage to the workpiece, do not aim the spray gun at any dust or debris.

!WARNING

Do not use pressure that exceeds the operating pressure of any of the parts (hoses, fittings, etc.) in the painting system.

Keep hose away

! CAUTION from sharp objects. Bursting air hoses may cause injury. Examine air hoses regularly and replace if damaged.

7. Always use a pressure regulator on the air supply to the spray gun.

NOTICE

appropriate water/oil removal equipment may result in damage to machinery or workpiece.

Do not misuse this

!WARNING product. Excessive exposure to vibration, work in awkward positions, and repetitive work motions can cause injury to hands and arms. Stop using any tool if discomfort, numbness, tingling, or pain occur, and consult a physician.

CALIFORNIA PROPOSITION 65

!DANGER

You can create dust when you cut, sand, drill or grind materials such as wood, paint, metal, concrete,

cement, or other masonry. This dust often contains chemicals known to cause cancer, birth defects, or other reproductive harm. Wear protective gear.

Set Up

USE OF AIR CAPS

Internal

used with fast drying paints and lacquers which will clog the opening in the air cap. INTERNAL MIX CAPS

MUST BE USED WITH PRESSURE FEED OPERATION.

External

THESE CAPS CAN BE USED WITH EITHER SIPHON OR PRESSURE FEED.

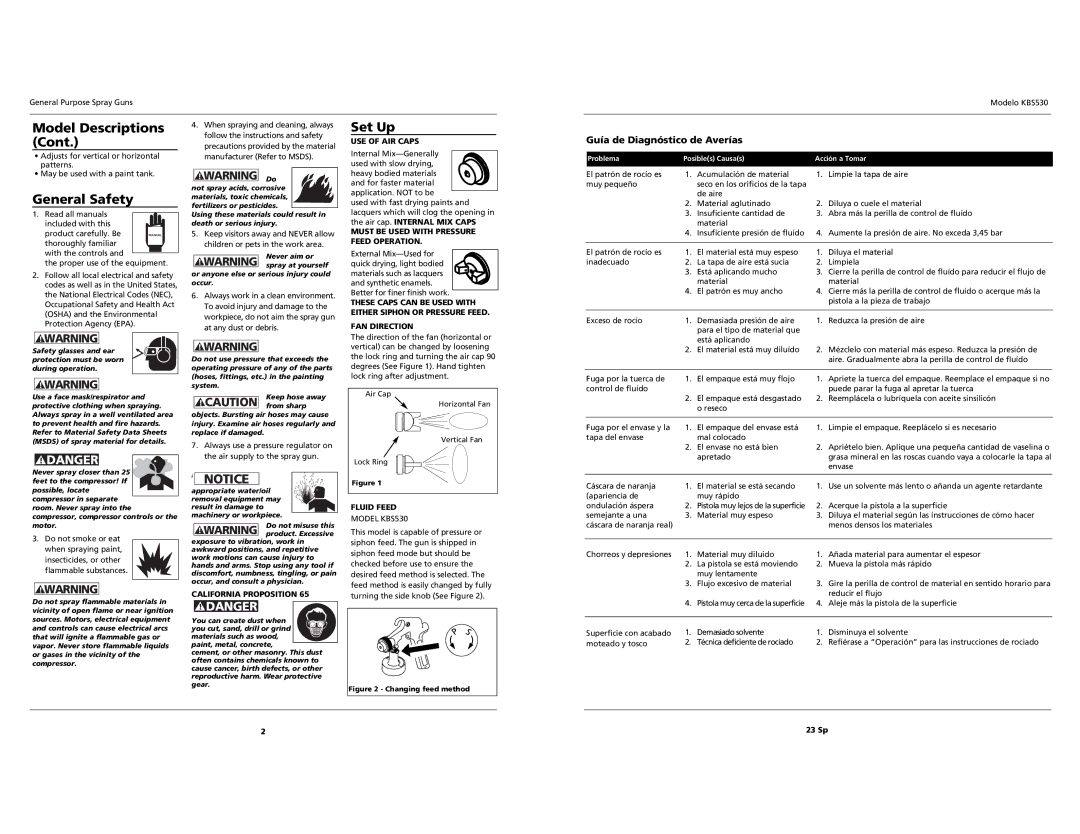

FAN DIRECTION

The direction of the fan (horizontal or vertical) can be changed by loosening the lock ring and turning the air cap 90 degrees (See Figure 1). Hand tighten lock ring after adjustment.

Air Cap

Horizontal Fan

Vertical Fan

Lock Ring

Figure 1

FLUID FEED

MODEL KBS530

This model is capable of pressure or siphon feed. The gun is shipped in siphon feed mode but should be checked before use to ensure the desired feed method is selected. The feed method is easily changed by fully turning the side knob (See Figure 2).

P S |

Figure 2 - Changing feed method |

Guía de Diagnóstico de Averías

| Problema | Posible(s) Causa(s) | Acción a Tomar | ||

El patrón de rocío es | 1. | Acumulación de material | 1. | Limpie la tapa de aire | |

muy pequeño |

| seco en los orificios de la tapa |

|

| |

|

|

| de aire |

|

|

|

| 2. | Material aglutinado | 2. | Diluya o cuele el material |

|

| 3. | Insuficiente cantidad de | 3. | Abra más la perilla de control de fluído |

|

|

| material |

|

|

|

| 4. | Insuficiente presión de fluído | 4. | Aumente la presión de aire. No exceda 3,45 bar |

|

|

|

|

| |

El patrón de rocío es | 1. | El material está muy espeso | 1. | Diluya el material | |

inadecuado | 2. | La tapa de aire está sucia | 2. | Límpiela | |

|

| 3. | Está aplicando mucho | 3. | Cierre la perilla de control de fluído para reducir el flujo de |

|

|

| material |

| material |

|

| 4. | El patrón es muy ancho | 4. | Cierre más la perilla de control de fluído o acerque más la |

|

|

|

|

| pistola a la pieza de trabajo |

|

|

|

|

| |

Exceso de rocío | 1. | Demasiada presión de aire | 1. | Reduzca la presión de aire | |

|

|

| para el tipo de material que |

|

|

|

|

| está aplicando |

|

|

|

| 2. | El material está muy diluído | 2. | Mézclelo con material más espeso. Reduzca la presión de |

|

|

|

|

| aire. Gradualmente abra la perilla de control de fluído |

|

|

|

|

| |

Fuga por la tuerca de | 1. | El empaque está muy flojo | 1. | Apriete la tuerca del empaque. Reemplace el empaque si no | |

control de fluído |

|

|

| puede parar la fuga al apretar la tuerca | |

|

| 2. | El empaque está desgastado | 2. | Reemplácela o lubríquela con aceite sinsilicón |

|

|

| o reseco |

|

|

|

|

|

|

| |

Fuga por el envase y la | 1. | El empaque del envase está | 1. | Limpie el empaque. Reeplácelo si es necesario | |

tapa del envase |

| mal colocado |

|

| |

|

| 2. | El envase no está bien | 2. | Apriételo bien. Aplique una pequeña cantidad de vaselina o |

|

|

| apretado |

| grasa mineral en las roscas cuando vaya a colocarle la tapa al |

|

|

|

|

| envase |

|

|

|

|

| |

Cáscara de naranja | 1. | El material se está secando | 1. | Use un solvente más lento o añanda un agente retardante | |

(apariencia de |

| muy rápido |

|

| |

ondulación áspera | 2. | Pistola muy lejos de la superficie | 2. | Acerque la pistola a la superficie | |

semejante a una | 3. | Material muy espeso | 3. | Diluya el material según las instrucciones de cómo hacer | |

cáscara de naranja real) |

|

|

| menos densos los materiales | |

|

|

|

|

| |

Chorreos y depresiones | 1. | Material muy diluido | 1. | Añada material para aumentar el espesor | |

|

| 2. | La pistola se está moviendo | 2. | Mueva la pistola más rápido |

|

|

| muy lentamente |

|

|

|

| 3. | Flujo excesivo de material | 3. | Gire la perilla de control de material en sentido horario para |

|

|

|

|

| reducir el flujo |

|

| 4. | Pistola muy cerca de la superficie | 4. | Aleje más la pistola de la superficie |

|

|

|

|

| |

Superficie con acabado | 1. | Demasiado solvente | 1. | Disminuya el solvente | |

moteado y tosco | 2. | Técnica deficiente de rociado | 2. | Refiérase a “Operación” para las instrucciones de rociado | |

2 | 23 Sp |