Operating Instructions

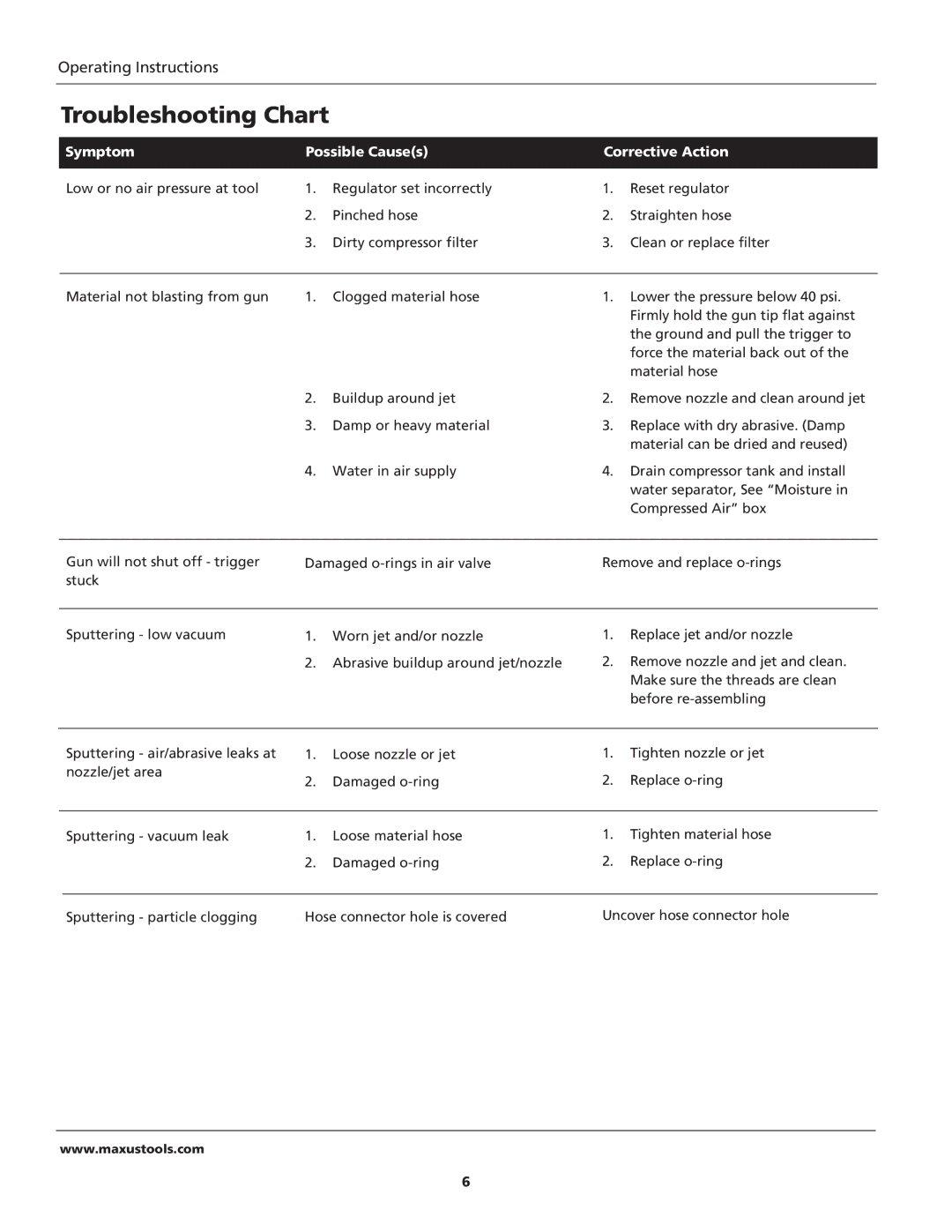

Troubleshooting Chart

Symptom | Possible Cause(s) | Corrective Action | ||

|

|

|

|

|

Low or no air pressure at tool | 1. | Regulator set incorrectly | 1. | Reset regulator |

| 2. | Pinched hose | 2. | Straighten hose |

| 3. | Dirty compressor filter | 3. | Clean or replace filter |

|

|

|

|

|

Material not blasting from gun | 1. | Clogged material hose | 1. | Lower the pressure below 40 psi. |

|

|

|

| Firmly hold the gun tip flat against |

|

|

|

| the ground and pull the trigger to |

|

|

|

| force the material back out of the |

|

|

|

| material hose |

| 2. | Buildup around jet | 2. | Remove nozzle and clean around jet |

| 3. | Damp or heavy material | 3. | Replace with dry abrasive. (Damp |

|

|

|

| material can be dried and reused) |

| 4. | Water in air supply | 4. | Drain compressor tank and install |

|

|

|

| water separator, See “Moisture in |

|

|

|

| Compressed Air” box |

|

|

| ||

Gun will not shut off - trigger | Damaged | Remove and replace | ||

stuck |

|

|

|

|

Sputtering - low vacuum | 1. | Worn jet and/or nozzle |

| 2. | Abrasive buildup around jet/nozzle |

1.Replace jet and/or nozzle

2.Remove nozzle and jet and clean. Make sure the threads are clean before

| Sputtering - air/abrasive leaks at | 1. | Loose nozzle or jet | 1. | Tighten nozzle or jet |

| nozzle/jet area | 2. | Damaged | 2. | Replace |

|

| ||||

|

|

|

|

|

|

| Sputtering - vacuum leak | 1. | Loose material hose | 1. | Tighten material hose |

|

| 2. | Damaged | 2. | Replace |

|

|

|

| ||

| Sputtering - particle clogging | Hose connector hole is covered | Uncover hose connector hole | ||

www.maxustools.com

6