MXS3000

Common Abrasive Media

Crushed glass is very aggressive. Used for economical, general

Plastic is available in a variety of sizes and materials (urea, acrylic, polyester, and melamine). These materials are ideal for application such as auto restoration to deliver a high stripping rate without damaging or warping the substrate material.

Brown aluminum oxide is a widely used abrasive media. This media produces a textured surface, good for repairing surfaces for recoating. It is excellent for removing heavy foreign materials, deburring, and etching glass and stone. It is a

White aluminum oxide can be used in the same applications as the brown aluminum oxide, but white aluminum oxide is considered to be a clean media, used in high performance processes where contamination of metal oxide must be kept to a minimum.

Aluminum / glass mixtures provides a combination of glass bead finishing and aluminum oxide cleaning. It provides a brighter finish than single abrasives, and it is good for removing rust and machine marks on metal.

Silicon carbide is the hardest abrasive material available. It is fast cutting and can be reused many times. It is high in initial cost, but removes material quickly to reduce blasting time.

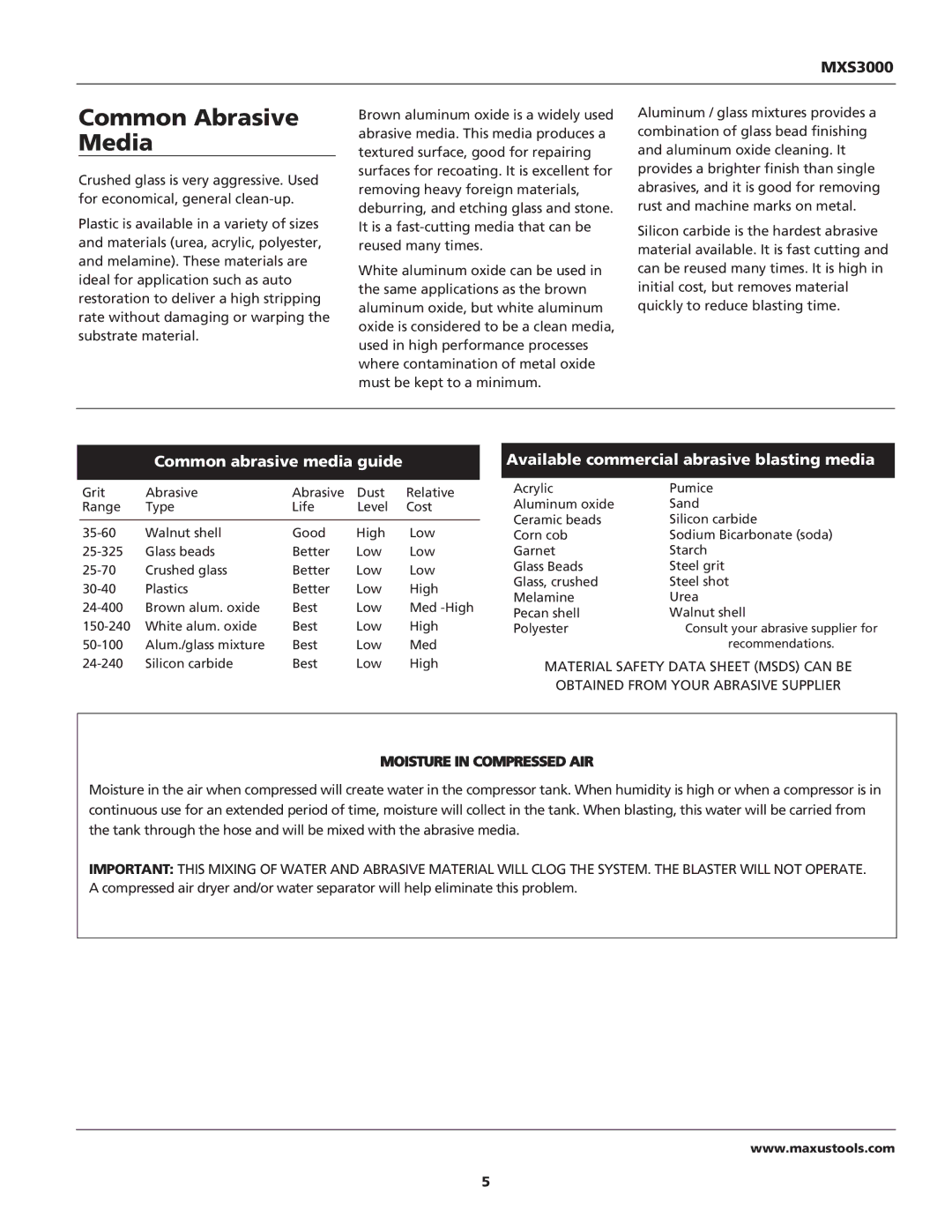

Common abrasive media guide

Grit | Abrasive | Abrasive | Dust | Relative |

Range | Type | Life | Level | Cost |

|

|

|

|

|

Walnut shell | Good | High | Low | |

Glass beads | Better | Low | Low | |

Crushed glass | Better | Low | Low | |

Plastics | Better | Low | High | |

Brown alum. oxide | Best | Low | Med | |

White alum. oxide | Best | Low | High | |

Alum./glass mixture | Best | Low | Med | |

Silicon carbide | Best | Low | High |

Available commercial abrasive blasting media

Acrylic | Pumice |

Aluminum oxide | Sand |

Ceramic beads | Silicon carbide |

Corn cob | Sodium Bicarbonate (soda) |

Garnet | Starch |

Glass Beads | Steel grit |

Glass, crushed | Steel shot |

Melamine | Urea |

Pecan shell | Walnut shell |

Polyester | Consult your abrasive supplier for |

| recommendations. |

MATERIAL SAFETY DATA SHEET (MSDS) CAN BE OBTAINED FROM YOUR ABRASIVE SUPPLIER

MOISTURE IN COMPRESSED AIR

Moisture in the air when compressed will create water in the compressor tank. When humidity is high or when a compressor is in continuous use for an extended period of time, moisture will collect in the tank. When blasting, this water will be carried from the tank through the hose and will be mixed with the abrasive media.

IMPORTANT: THIS MIXING OF WATER AND ABRASIVE MATERIAL WILL CLOG THE SYSTEM. THE BLASTER WILL NOT OPERATE. A compressed air dryer and/or water separator will help eliminate this problem.

www.maxustools.com

5