Wire Feed Arc Welder

For Information About This Product, Call

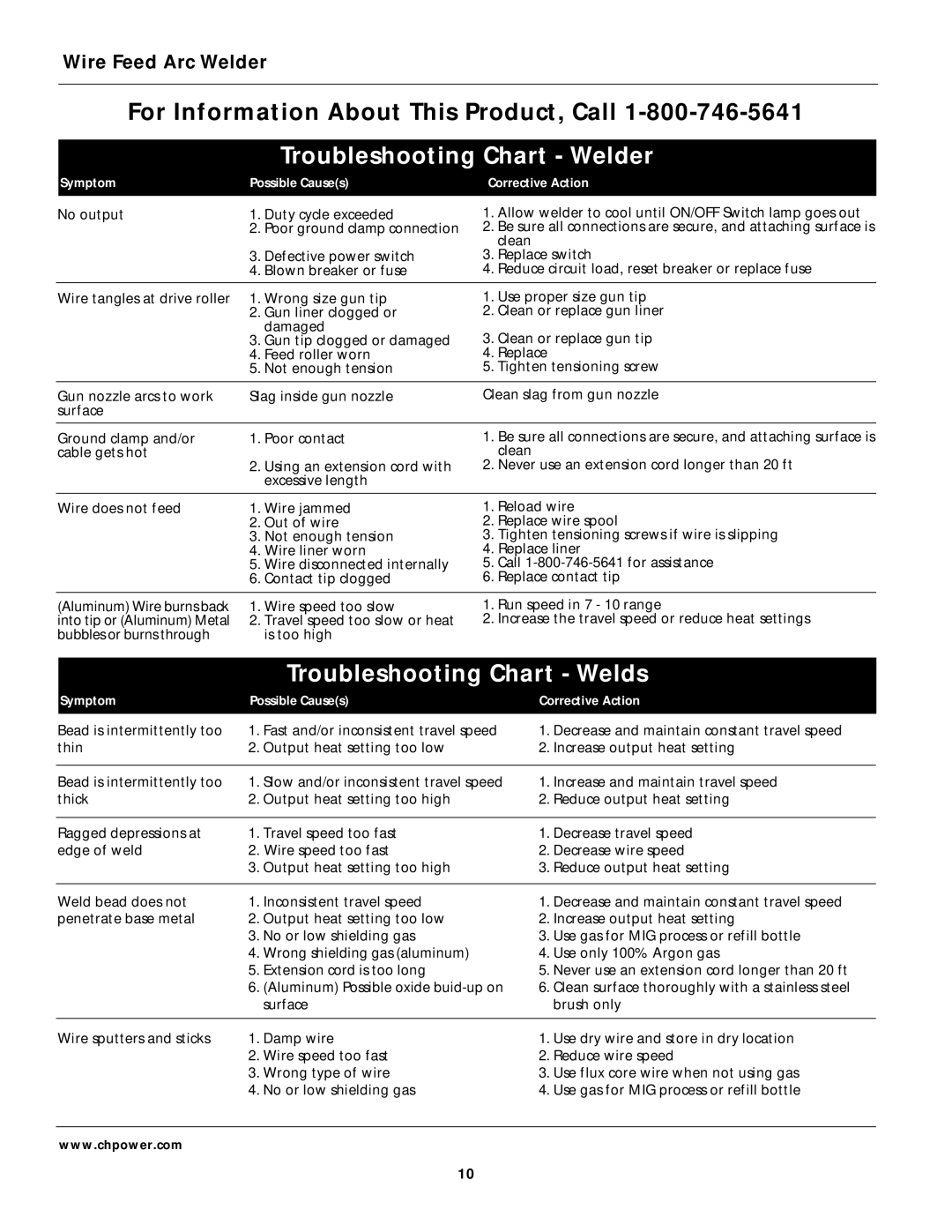

Troubleshooting Chart - Welder

Symptom | Possible Cause(s) | Corrective Action |

No output | 1. Duty cycle exceeded | 1. Allow welder to cool until ON/OFF Switch lamp goes out |

| 2. Poor ground clamp connection | 2. Be sure all connections are secure, and attaching surface is |

|

| clean |

| 3. Defective power switch | 3. Replace switch |

| 4. Blown breaker or fuse | 4. Reduce circuit load, reset breaker or replace fuse |

|

|

|

Wire tangles at drive roller | 1. Wrong size gun tip | 1. Use proper size gun tip |

| 2. Gun liner clogged or | 2. Clean or replace gun liner |

| damaged | 3. Clean or replace gun tip |

| 3. Gun tip clogged or damaged | |

| 4. Feed roller worn | 4. Replace |

| 5. Not enough tension | 5. Tighten tensioning screw |

|

|

|

Gun nozzle arcs to work | Slag inside gun nozzle | Clean slag from gun nozzle |

surface |

|

|

|

|

|

Ground clamp and/or | 1. Poor contact | 1. Be sure all connections are secure, and attaching surface is |

cable gets hot |

| clean |

| 2. Using an extension cord with | 2. Never use an extension cord longer than 20 ft |

| excessive length |

|

|

|

|

Wire does not feed | 1. Wire jammed | 1. Reload wire |

| 2. Out of wire | 2. Replace wire spool |

| 3. Not enough tension | 3. Tighten tensioning screws if wire is slipping |

| 4. Wire liner worn | 4. Replace liner |

| 5. Wire disconnected internally | 5. Call |

| 6. Contact tip clogged | 6. Replace contact tip |

|

|

|

(Aluminum) Wire burns back | 1. Wire speed too slow | 1. Run speed in 7 - 10 range |

into tip or (Aluminum) Metal | 2. Travel speed too slow or heat | 2. Increase the travel speed or reduce heat settings |

bubbles or burns through | is too high |

|

Troubleshooting Chart - Welds

Symptom | Possible Cause(s) | Corrective Action |

Bead is intermittently too | 1. Fast and/or inconsistent travel speed | 1. Decrease and maintain constant travel speed |

thin | 2. Output heat setting too low | 2. Increase output heat setting |

|

|

|

Bead is intermittently too | 1. Slow and/or inconsistent travel speed | 1. Increase and maintain travel speed |

thick | 2. Output heat setting too high | 2. Reduce output heat setting |

|

|

|

Ragged depressions at | 1. Travel speed too fast | 1. Decrease travel speed |

edge of weld | 2. Wire speed too fast | 2. Decrease wire speed |

| 3. Output heat setting too high | 3. Reduce output heat setting |

|

|

|

Weld bead does not | 1. Inconsistent travel speed | 1. Decrease and maintain constant travel speed |

penetrate base metal | 2. Output heat setting too low | 2. Increase output heat setting |

| 3. No or low shielding gas | 3. Use gas for MIG process or refill bottle |

| 4. Wrong shielding gas (aluminum) | 4. Use only 100% Argon gas |

| 5. Extension cord is too long | 5. Never use an extension cord longer than 20 ft |

| 6. (Aluminum) Possible oxide | 6. Clean surface thoroughly with a stainless steel |

| surface | brush only |

|

|

|

Wire sputters and sticks | 1. Damp wire | 1. Use dry wire and store in dry location |

| 2. Wire speed too fast | 2. Reduce wire speed |

| 3. Wrong type of wire | 3. Use flux core wire when not using gas |

| 4. No or low shielding gas | 4. Use gas for MIG process or refill bottle |

|

|

|

www.chpower.com |

|

|

10