Operating Instructions | Model WT6100 |

|

|

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

TIG Torch

BUILT TO LAST

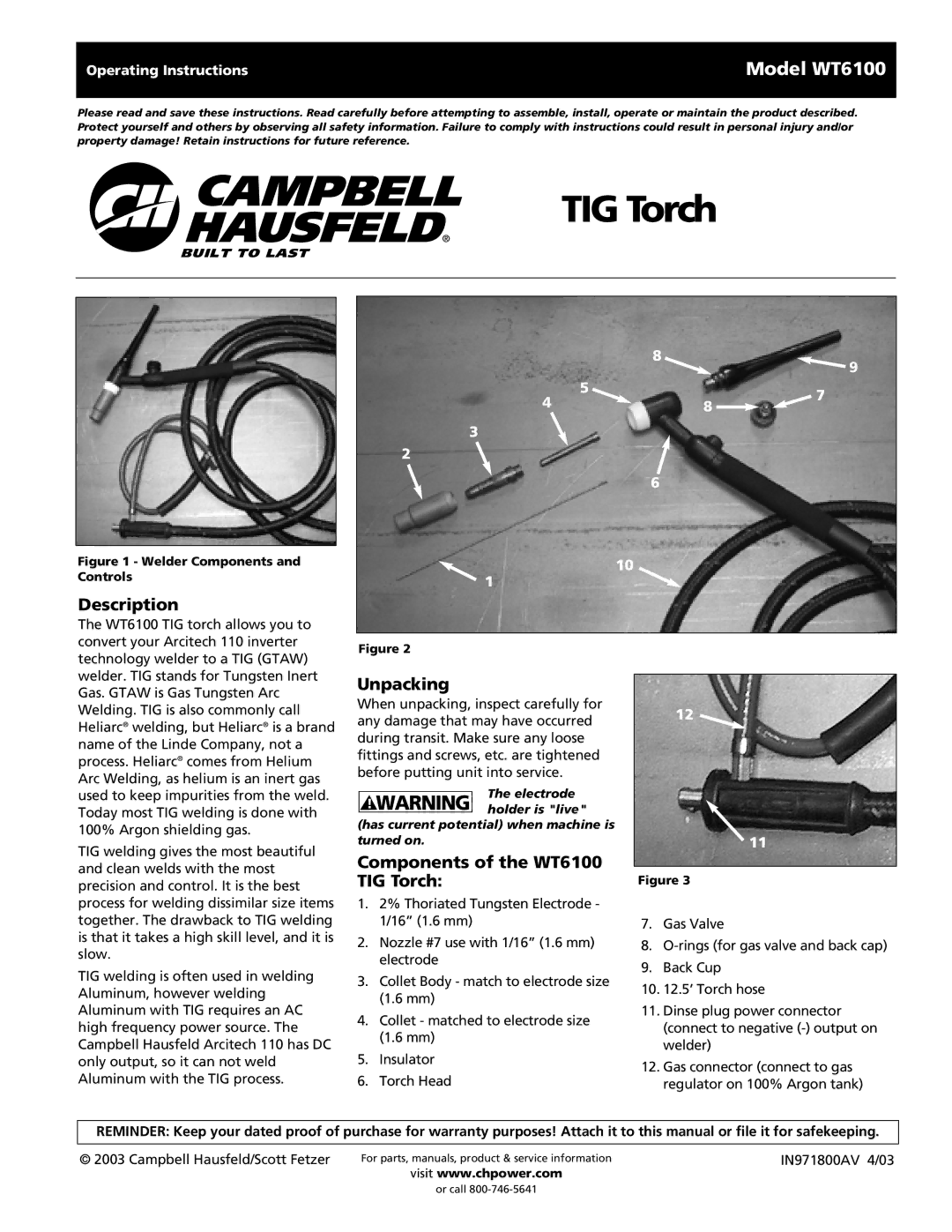

Figure 1 - Welder Components and Controls

Description

The WT6100 TIG torch allows you to convert your Arcitech 110 inverter technology welder to a TIG (GTAW) welder. TIG stands for Tungsten Inert

|

| 8 |

|

| 9 |

4 | 5 | 7 |

| ||

| 8 |

3

2

6

10

1

Figure 2

Gas. GTAW is Gas Tungsten Arc Welding. TIG is also commonly call Heliarc® welding, but Heliarc® is a brand name of the Linde Company, not a process. Heliarc® comes from Helium Arc Welding, as helium is an inert gas used to keep impurities from the weld. Today most TIG welding is done with 100% Argon shielding gas.

TIG welding gives the most beautiful and clean welds with the most precision and control. It is the best process for welding dissimilar size items together. The drawback to TIG welding is that it takes a high skill level, and it is slow.

TIG welding is often used in welding Aluminum, however welding Aluminum with TIG requires an AC high frequency power source. The Campbell Hausfeld Arcitech 110 has DC only output, so it can not weld Aluminum with the TIG process.

Unpacking

When unpacking, inspect carefully for any damage that may have occurred during transit. Make sure any loose fittings and screws, etc. are tightened before putting unit into service.

| The electrode | |

! WARNING | ||

holder is "live" | ||

|

(has current potential) when machine is turned on.

Components of the WT6100 TIG Torch:

1.2% Thoriated Tungsten Electrode - 1/16” (1.6 mm)

2.Nozzle #7 use with 1/16” (1.6 mm) electrode

3.Collet Body - match to electrode size (1.6 mm)

4.Collet - matched to electrode size (1.6 mm)

5.Insulator

6.Torch Head

12

11

Figure 3

7.Gas Valve

8.

9.Back Cup

10.12.5’ Torch hose

11.Dinse plug power connector (connect to negative

12.Gas connector (connect to gas regulator on 100% Argon tank)

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2003 Campbell Hausfeld/Scott Fetzer | For parts, manuals, product & service information | IN971800AV 4/03 |

visit www.chpower.com

or call