38VYX110, 38VYX130 specifications

The Carrier 38VYX130 and 38VYX110 are advanced air conditioning units designed for residential and light commercial applications, offering optimal energy efficiency, reliable performance, and enhanced comfort. These models exemplify Carrier's commitment to delivering high-quality climate control solutions.One of the standout features of the Carrier 38VYX series is its energy efficiency. Both the 38VYX130 and 38VYX110 boast a high Seasonal Energy Efficiency Ratio (SEER) rating, indicating their ability to provide effective cooling while consuming less energy. This makes them an environmentally friendly option, as well as a cost-effective choice for homeowners and businesses looking to reduce their energy bills.

The 38VYX130 and 38VYX110 utilize inverter technology, which allows the compressor to adjust its speed based on the cooling demand. This not only enhances energy efficiency but also ensures consistent comfort levels by minimizing temperature fluctuations. This feature is particularly beneficial in variable weather conditions, providing a stable indoor climate without excessive energy consumption.

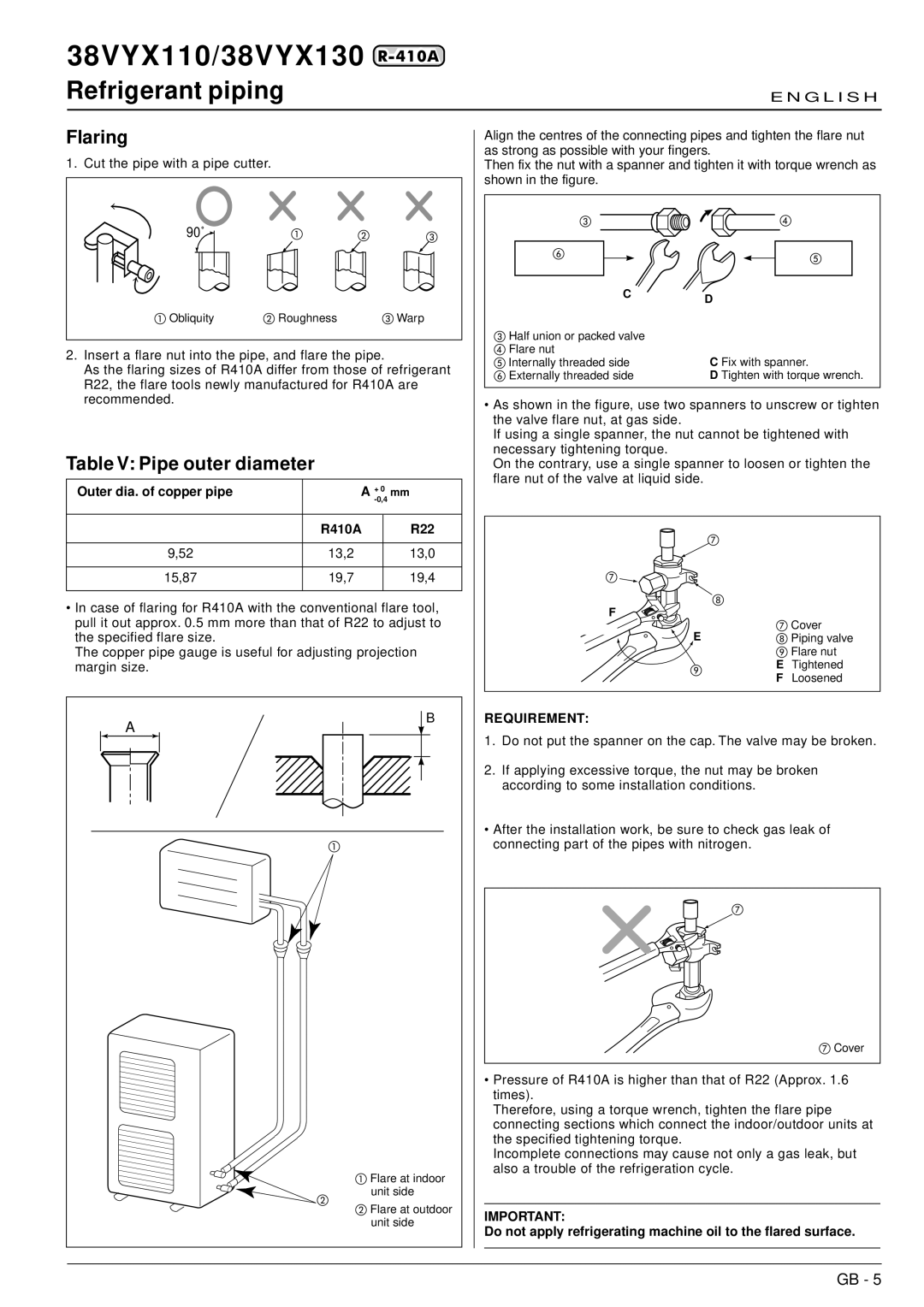

Another significant technological advancement in these models is the use of R-410A refrigerant, which is known for its low environmental impact compared to traditional refrigerants. This aligns with Carrier's commitment to sustainability and reducing the carbon footprint of their products. Additionally, both units are equipped with advanced filtration systems that help improve indoor air quality by capturing dust, allergens, and other airborne particles.

The Carrier 38VYX series is also designed with quiet operation in mind. With sound levels that fall within the low dB range, these units ensure that homeowners can enjoy a comfortable living environment without disruptive noise, whether the system is running during the day or at night.

For ease of installation and maintenance, the 38VYX130 and 38VYX110 come with user-friendly features, including a compact design that allows for flexible placement and service access. Furthermore, Carrier offers a robust warranty and customer support, ensuring peace of mind for users.

In conclusion, the Carrier 38VYX130 and 38VYX110 are exceptional choices for those looking for efficient, reliable, and quiet air conditioning systems. With their advanced technologies and commitment to sustainability, these models are set to provide superior comfort for years to come.