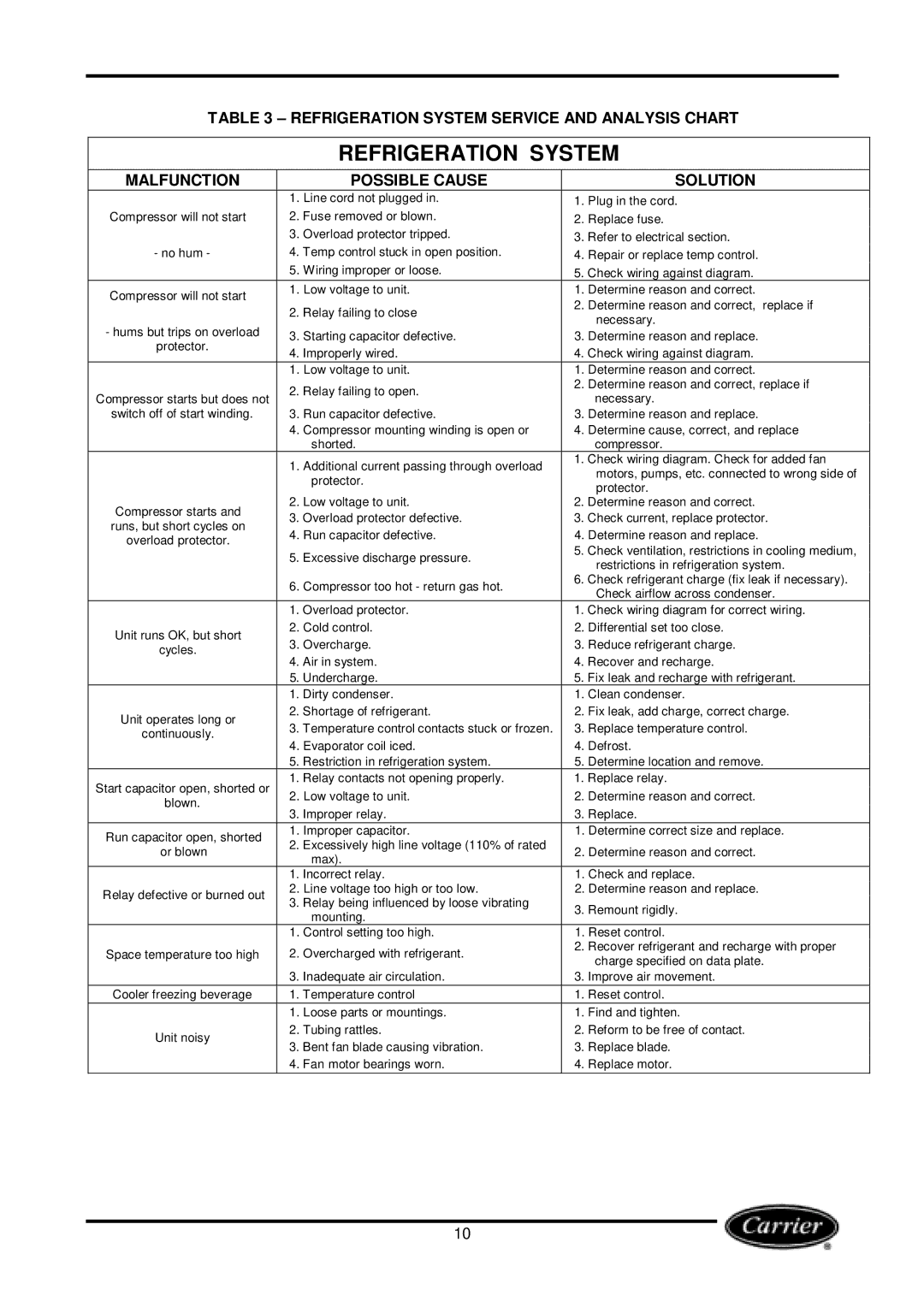

TABLE 3 – REFRIGERATION SYSTEM SERVICE AND ANALYSIS CHART

REFRIGERATION SYSTEM

MALFUNCTION |

| POSSIBLE CAUSE |

| SOLUTION | |

| 1. | Line cord not plugged in. | 1. | Plug in the cord. | |

Compressor will not start | 2. Fuse removed or blown. | 2. | Replace fuse. | ||

| 3. | Overload protector tripped. | 3. | Refer to electrical section. | |

- no hum - | 4. Temp control stuck in open position. | 4. | Repair or replace temp control. | ||

| 5. | Wiring improper or loose. | 5. | Check wiring against diagram. | |

Compressor will not start | 1. | Low voltage to unit. | 1. | Determine reason and correct. | |

|

| 2. | Determine reason and correct, replace if | ||

| 2. | Relay failing to close | |||

|

| necessary. | |||

- hums but trips on overload |

|

|

| ||

3. | Starting capacitor defective. | 3. | Determine reason and replace. | ||

protector. | |||||

4. | Improperly wired. | 4. | Check wiring against diagram. | ||

| |||||

| 1. | Low voltage to unit. | 1. | Determine reason and correct. | |

| 2. | Relay failing to open. | 2. | Determine reason and correct, replace if | |

Compressor starts but does not |

| necessary. | |||

|

|

| |||

switch off of start winding. | 3. Run capacitor defective. | 3. | Determine reason and replace. | ||

| 4. | Compressor mounting winding is open or | 4. | Determine cause, correct, and replace | |

|

| shorted. |

| compressor. | |

| 1. | Additional current passing through overload | 1. | Check wiring diagram. Check for added fan | |

|

| motors, pumps, etc. connected to wrong side of | |||

|

| protector. |

| ||

|

|

| protector. | ||

|

|

|

| ||

Compressor starts and | 2. | Low voltage to unit. | 2. | Determine reason and correct. | |

3. | Overload protector defective. | 3. | Check current, replace protector. | ||

runs, but short cycles on | |||||

4. | Run capacitor defective. | 4. | Determine reason and replace. | ||

overload protector. | |||||

|

| 5. | Check ventilation, restrictions in cooling medium, | ||

| 5. | Excessive discharge pressure. | |||

|

| restrictions in refrigeration system. | |||

|

|

|

| ||

| 6. | Compressor too hot - return gas hot. | 6. | Check refrigerant charge (fix leak if necessary). | |

|

| Check airflow across condenser. | |||

|

|

|

| ||

| 1. | Overload protector. | 1. | Check wiring diagram for correct wiring. | |

Unit runs OK, but short | 2. | Cold control. | 2. | Differential set too close. | |

3. | Overcharge. | 3. | Reduce refrigerant charge. | ||

cycles. | |||||

4. | Air in system. | 4. | Recover and recharge. | ||

| |||||

| 5. | Undercharge. | 5. | Fix leak and recharge with refrigerant. | |

| 1. | Dirty condenser. | 1. | Clean condenser. | |

Unit operates long or | 2. | Shortage of refrigerant. | 2. | Fix leak, add charge, correct charge. | |

3. | Temperature control contacts stuck or frozen. | 3. | Replace temperature control. | ||

continuously. | |||||

4. | Evaporator coil iced. | 4. | Defrost. | ||

| |||||

| 5. | Restriction in refrigeration system. | 5. | Determine location and remove. | |

Start capacitor open, shorted or | 1. | Relay contacts not opening properly. | 1. | Replace relay. | |

2. | Low voltage to unit. | 2. | Determine reason and correct. | ||

blown. | |||||

3. | Improper relay. | 3. | Replace. | ||

| |||||

Run capacitor open, shorted | 1. | Improper capacitor. | 1. Determine correct size and replace. | ||

2. | Excessively high line voltage (110% of rated |

|

| ||

or blown | 2. Determine reason and correct. | ||||

| max). | ||||

|

|

|

| ||

| 1. | Incorrect relay. | 1. Check and replace. | ||

Relay defective or burned out | 2. | Line voltage too high or too low. | 2. Determine reason and replace. | ||

3. | Relay being influenced by loose vibrating |

|

| ||

| 3. Remount rigidly. | ||||

|

| mounting. | |||

|

|

|

| ||

| 1. | Control setting too high. | 1. Reset control. | ||

Space temperature too high | 2. Overcharged with refrigerant. | 2. Recover refrigerant and recharge with proper | |||

| charge specified on data plate. | ||||

|

|

|

| ||

| 3. | Inadequate air circulation. | 3. Improve air movement. | ||

Cooler freezing beverage | 1. Temperature control | 1. | Reset control. | ||

| 1. | Loose parts or mountings. | 1. | Find and tighten. | |

Unit noisy | 2. | Tubing rattles. | 2. | Reform to be free of contact. | |

3. | Bent fan blade causing vibration. | 3. | Replace blade. | ||

| |||||

| 4. | Fan motor bearings worn. | 4. | Replace motor. | |

|

|

|

|

| |

10