5) CHECK DISPENSE VALVES FOR LIME

Remove The Valves And Clean. You Can Take These Valves Apart By Hand As Shown. Replace The Assembly As Needed.

Replace The Valve Into The Tank And Refill tank.

The SINGLE DISPENSE VALVE is factory adjusted to dispense 0.35 oz./sec. of water during the brew cycle (spray duration).

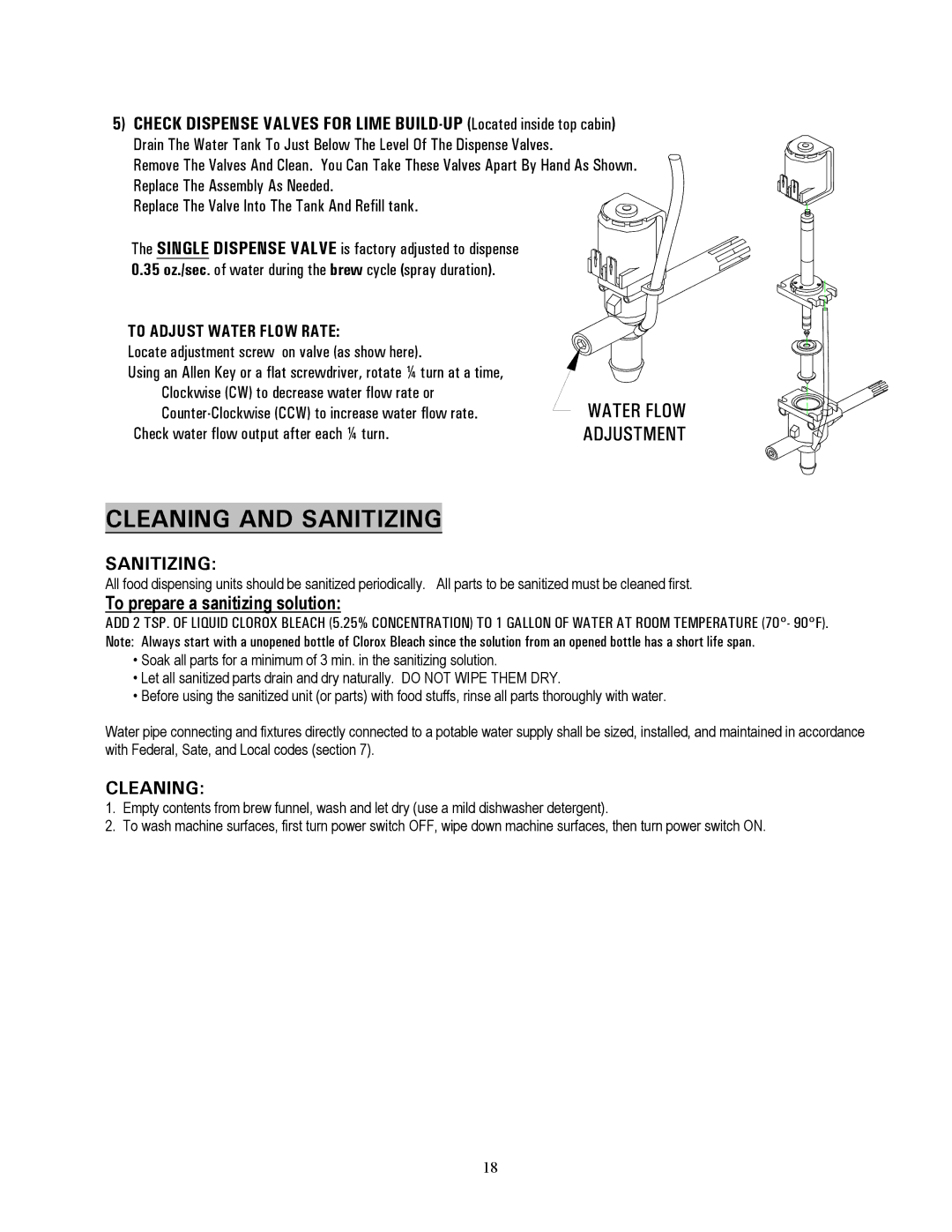

TO ADJUST WATER FLOW RATE:

Locate adjustment screw on valve (as show here).

Using an Allen Key or a flat screwdriver, rotate ¼ turn at a time,

Clockwise (CW) to decrease water flow rate or

Check water flow output after each ¼ turn.

CLEANING AND SANITIZING

SANITIZING:

All food dispensing units should be sanitized periodically. All parts to be sanitized must be cleaned first.

To prepare a sanitizing solution:

ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25% CONCENTRATION) TO 1 GALLON OF WATER AT ROOM TEMPERATURE (70°- 90°F). Note: Always start with a unopened bottle of Clorox Bleach since the solution from an opened bottle has a short life span.

•Soak all parts for a minimum of 3 min. in the sanitizing solution.

•Let all sanitized parts drain and dry naturally. DO NOT WIPE THEM DRY.

•Before using the sanitized unit (or parts) with food stuffs, rinse all parts thoroughly with water.

Water pipe connecting and fixtures directly connected to a potable water supply shall be sized, installed, and maintained in accordance with Federal, Sate, and Local codes (section 7).

CLEANING:

1.Empty contents from brew funnel, wash and let dry (use a mild dishwasher detergent).

2.To wash machine surfaces, first turn power switch OFF, wipe down machine surfaces, then turn power switch ON.

18