800A, 600A specifications

The Chamberlain 600A and 800A are innovative garage door openers designed to meet the needs of modern homeowners looking for security, convenience, and advanced technology. Both models are part of Chamberlain's renowned lineup, known for their reliability and performance.The Chamberlain 600A features a robust, ½ horsepower motor, capable of lifting heavy wooden or insulated garage doors with ease. Its steel reinforcements ensure durability, while a chain drive system provides reliable and consistent operation. This opener is ideal for standard residential doors and boasts a lifting capacity of up to 500 pounds. An important highlight of the 600A is its myQ technology, which allows users to control and monitor their garage door remotely via a smartphone app. This feature enhances security and provides peace of mind, especially for those who frequently forget to close their garage doors.

On the other hand, the Chamberlain 800A takes advanced technology a step further with its 1.25 horsepower motor, allowing it to handle heavier and larger doors, up to 850 pounds. This model features a powerful belt drive system, which operates more quietly than traditional chain systems, making it a perfect choice for homes with living spaces adjacent to the garage. The 800A also includes the myQ technology, enabling users to receive real-time notifications and operate their garage door from anywhere, at any time.

Both models incorporate numerous safety features, including a safety reversing system that detects objects in the door’s path, reversing it to prevent accidents. Additionally, they come equipped with a durable exterior to withstand various weather conditions, ensuring longevity and sustained performance over time.

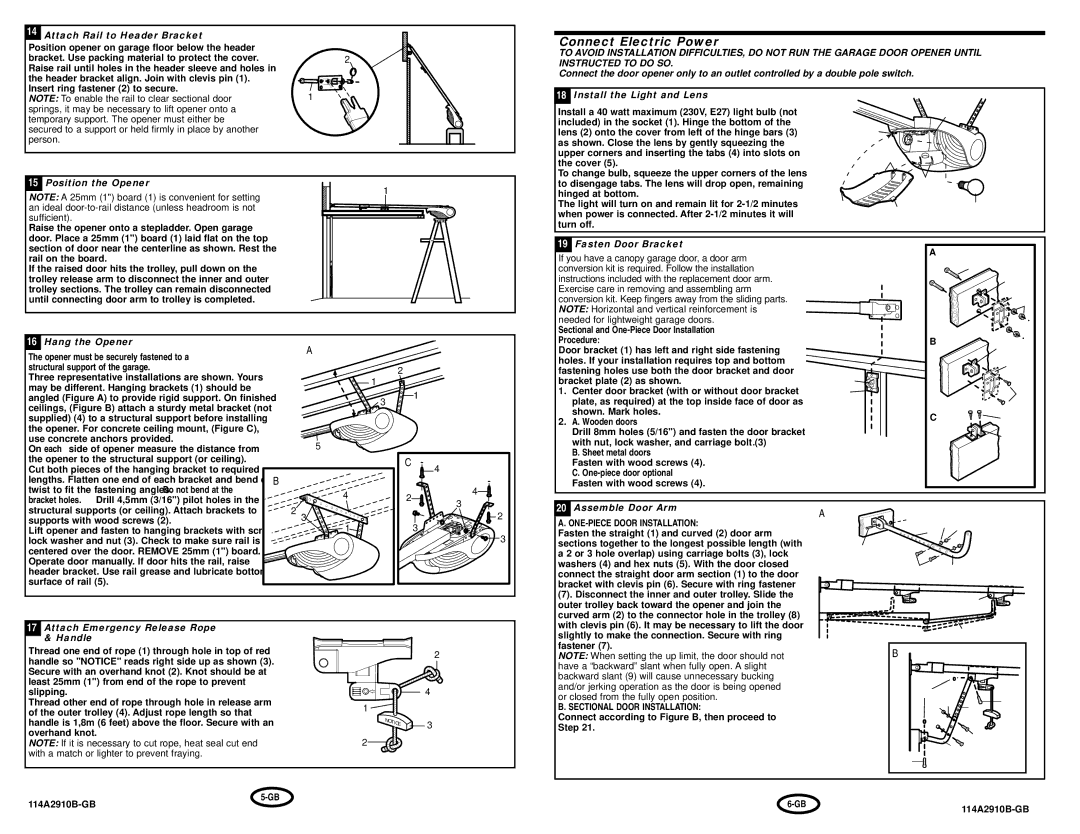

In terms of installation and maintenance, both the 600A and 800A are designed for user-friendly setup. The openers feature a simple assembly process and most homeowners can complete the installation in just a few hours.

In conclusion, the Chamberlain 600A and 800A garage door openers deliver a blend of power, safety, and technology. Whether you opt for the reliable 600A or the more robust 800A, both models exemplify Chamberlain's commitment to quality and customer satisfaction, making them a smart choice for enhancing home convenience and security.