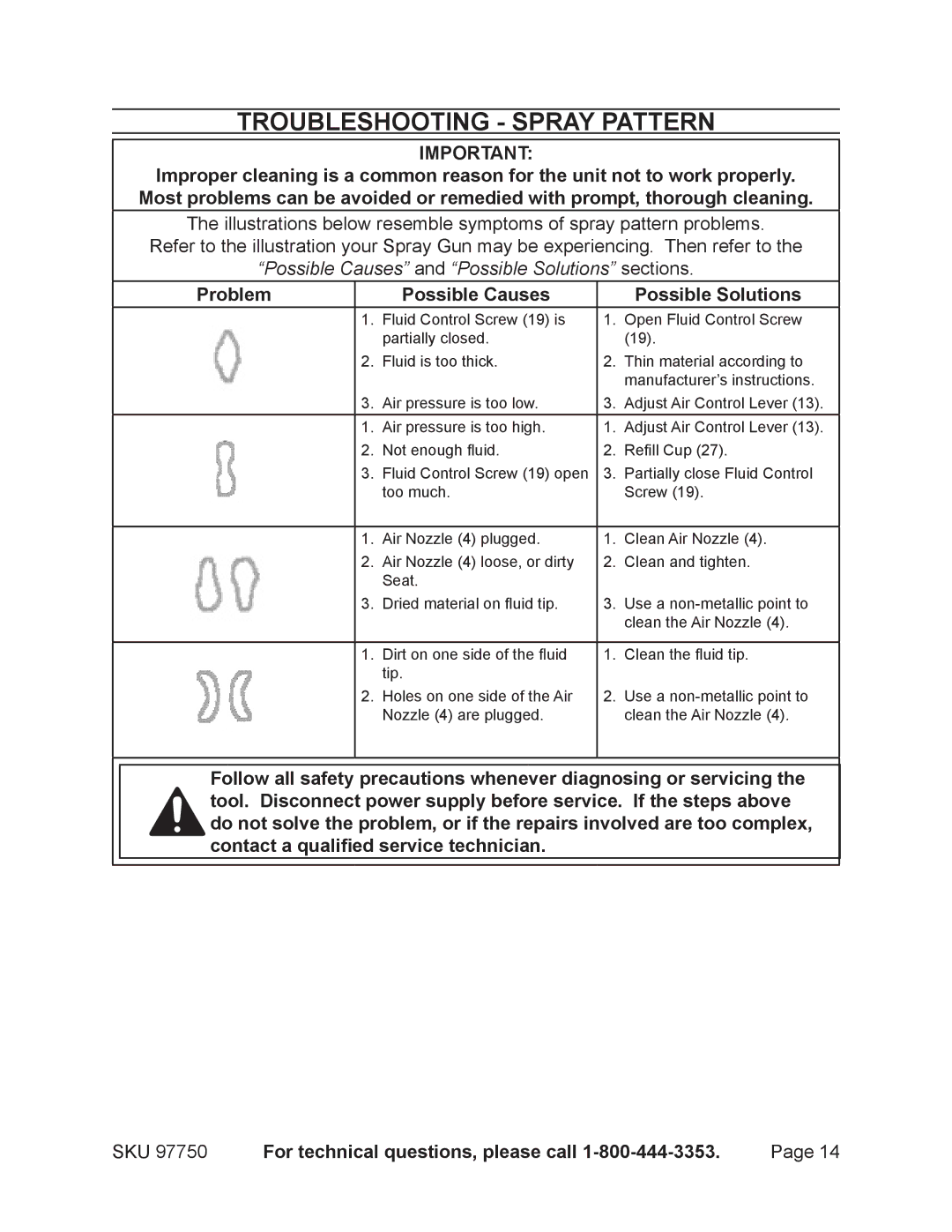

TROUBLESHOOTING - SPRAY PATTERN

IMPORTANT:

Improper cleaning is a common reason for the unit not to work properly. Most problems can be avoided or remedied with prompt, thorough cleaning.

The illustrations below resemble symptoms of spray pattern problems.

Refer to the illustration your Spray Gun may be experiencing. Then refer to the

“Possible Causes” and “Possible Solutions” sections.

Problem |

| Possible Causes |

| Possible Solutions |

| 1. | Fluid Control Screw (19) is | 1. | Open Fluid Control Screw |

|

| partially closed. |

| (19). |

| 2. | Fluid is too thick. | 2. | Thin material according to |

|

|

|

| manufacturer’s instructions. |

| 3. | Air pressure is too low. | 3. | Adjust Air Control Lever (13). |

| 1. | Air pressure is too high. | 1. | Adjust Air Control Lever (13). |

| 2. | Not enough fluid. | 2. | Refill Cup (27). |

| 3. | Fluid Control Screw (19) open | 3. | Partially close Fluid Control |

|

| too much. |

| Screw (19). |

|

|

|

|

|

| 1. | Air Nozzle (4) plugged. | 1. | Clean Air Nozzle (4). |

| 2. | Air Nozzle (4) loose, or dirty | 2. | Clean and tighten. |

|

| Seat. |

|

|

| 3. | Dried material on fluid tip. | 3. | Use a |

|

|

|

| clean the Air Nozzle (4). |

|

|

|

|

|

| 1. | Dirt on one side of the fluid | 1. | Clean the fluid tip. |

|

| tip. |

|

|

| 2. | Holes on one side of the Air | 2. | Use a |

|

| Nozzle (4) are plugged. |

| clean the Air Nozzle (4). |

|

|

|

|

|

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service. If the steps above do not solve the problem, or if the repairs involved are too complex, contact a qualified service technician.

SKU 97750 | For technical questions, please call | Page 14 |