PE429-1 specifications

The Chromalox PE429-1 is a cutting-edge industrial heating solution designed to cater to a wide range of applications, particularly in demanding environments. This innovative product embodies an impressive amalgamation of advanced technologies, ensuring optimal performance and efficiency.One of the hallmark features of the PE429-1 is its robust construction. Built to endure high temperatures and harsh conditions, the device is made from durable materials that resist wear and corrosion. This increases its longevity and decreases the need for frequent replacements or repairs, ultimately saving costs over time.

The PE429-1 also incorporates sophisticated temperature control technologies. With a precise digital thermostat, operators can easily set and monitor temperatures, ensuring that processes remain within desired parameters. This level of control not only enhances operational efficiency but also minimizes the risk of overheating, which could lead to equipment damage or safety hazards.

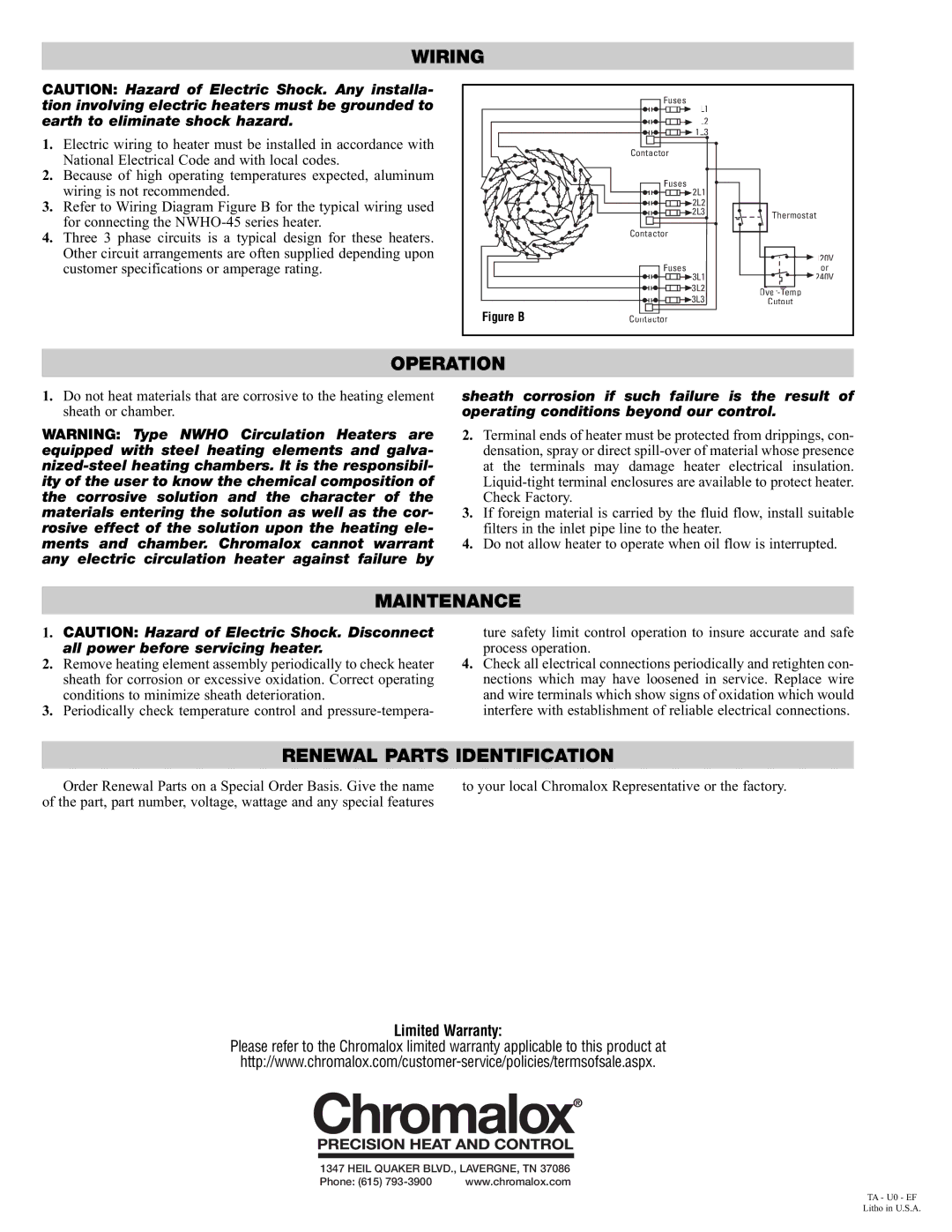

Moreover, the unit is equipped with advanced safety features that are paramount in industrial settings. Over-temperature protection, intricate wiring designed for reliability, and fail-safe mechanisms contribute to a secure and stable operating environment. These safety provisions are essential in preventing accidents and ensuring compliance with industry regulations.

Another key characteristic of the Chromalox PE429-1 is its versatility. This device can be utilized in various applications, including chemical processing, food manufacturing, and pharmaceutical production. Its ability to accommodate different watt densities and voltage requirements makes it a preferred choice for contractors and engineers looking for customizable solutions.

Energy efficiency is another significant advantage of the PE429-1. The design minimizes energy consumption while maintaining high performance levels, which is increasingly important in a landscape where sustainability and operational cost-effectiveness are paramount.

Additionally, the PE429-1 features an intuitive interface that promotes ease of use. Operators can quickly learn how to configure and operate the system, reducing training time and operational downtime.

In summary, the Chromalox PE429-1 stands out as a premier heating solution, showcasing durability, precise temperature control, enhanced safety features, versatility in applications, and energy efficiency. Its design and technological innovations make it a vital asset in modern industrial settings, ensuring optimal performance while contributing to safety and sustainability efforts.