WARNING

Failure to understand and follow these installation instructions and the WARNING notes contained therein may result in severe personal injury, death or substantial property damage.

1.To reduce the risk of ignition of hazardous atmospheres:

In accordance with the National Electrical Code, do not install where operating temperature code exceeds the ignition tempera- ture of the hazardous atmosphere. Use only in atmospheres hav- ing an ignition temperature higher than 165˚ C (329˚ F).

2.Disconnect from supply circuit before opening enclosures.

3.Hazard of Electric Shock. Heater must be effectively grounded in accordance with N.E.C. to eliminate shock hazard.

4.Heat exchanger contains Propylene Glycol under pressure at oper- ating temperature. A material safety data sheet (MSDS) is avail- able from Chromalox upon request. Should leakage occur, remove unit from service and investigate cause.

5.Keep all electrical enclosure covers tightly closed and secured with all bolts and threads. Cover joints must be clean before replacing covers.

6.Install and operate in upright position only. Refer to Figure 3 for level requirements. Failure to comply will cause overheating of the element and shutting down the unit by tripping the high tem- perature cutout.

7.All unused threaded openings not used for supply wiring must be fitted with threaded plugs approved for use in hazardous loca- tions.

8.All unit electrical installation fittings, conduit, wiring and seals must meet NEC and local codes for hazardous locations.

9.External line fusing or circuit breaker protection is required.

10.Hi limit cutouts must never be bypassed in the control circuit.

11.Alarm pilot lamp, if supplied, will turn on if the high limit control actuates. Steady on lamp indicates manual reset protector has tripped. This could result if the heat exchanger is obstructed (dirty), inlet air restricted or fan not turning. Shut off power to unit and refer to repair procedures section of instruction sheet.

12.Mounting clearances on nameplate must be observed.

13.Use copper wire for supply connections according to size and rat- ing on nameplate.

14.Do not install any type of gasket material on any of the electrical junction box cover surfaces.

15.Do not attempt to override louver stops or operate unit with lou- vers fully closed.

|

| Integral, heavy duty |

|

| Polyester | |

|

| magnetic contactor | Mounting bolt | |||

|

|

| heavy gauge steel corrosion | |||

|

|

| hanger connections | |||

| Explosion | resistant cabinet | ||||

|

|

| ||||

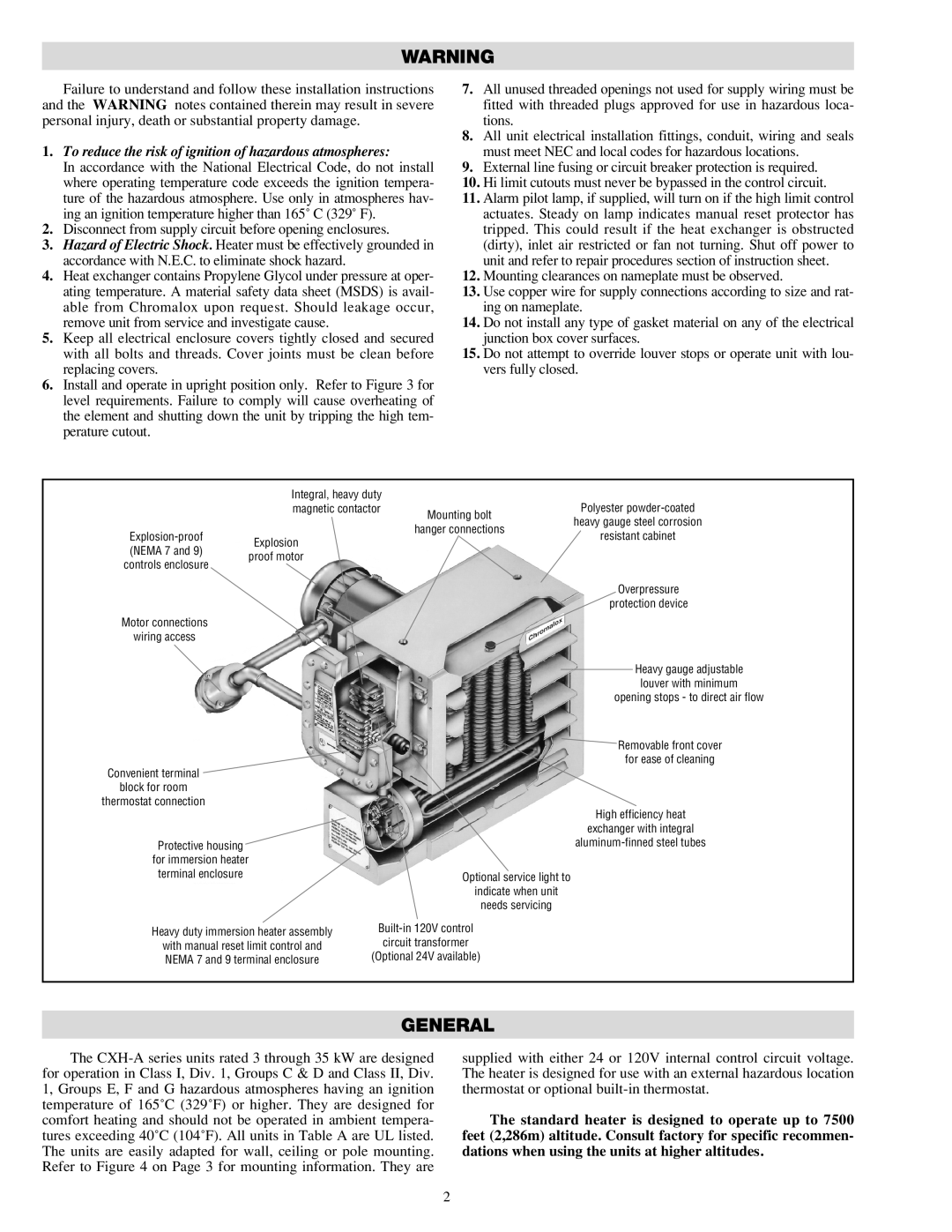

(NEMA 7 and 9) |

|

|

|

|

| |

proof motor |

|

|

|

| ||

controls enclosure |

|

|

|

| ||

|

|

|

|

|

| |

|

|

|

|

| Overpressure | |

|

|

|

|

| protection device | |

Motor connections |

|

|

|

|

|

|

wiring access |

|

|

|

|

|

|

|

|

|

|

|

| Heavy gauge adjustable |

|

|

|

|

|

| |

|

|

|

|

|

| louver with minimum |

|

|

|

|

| opening stops - to direct air flow | |

|

|

|

|

| Removable front cover | |

Convenient terminal |

|

|

|

| for ease of cleaning | |

|

|

|

|

|

| |

block for room |

|

|

|

|

|

|

thermostat connection |

|

|

|

| High efficiency heat | |

|

|

|

|

| ||

|

|

|

|

| exchanger with integral | |

Protective housing |

|

|

|

| ||

for immersion heater |

|

|

|

|

| |

terminal enclosure |

|

| Optional service light to |

|

| |

|

|

| indicate when unit |

|

| |

|

|

| needs servicing |

|

| |

Heavy duty immersion heater assembly

with manual reset limit control and NEMA 7 and 9 terminal enclosure

GENERAL

The

supplied with either 24 or 120V internal control circuit voltage. The heater is designed for use with an external hazardous location thermostat or optional

The standard heater is designed to operate up to 7500 feet (2,286m) altitude. Consult factory for specific recommen- dations when using the units at higher altitudes.

2