MAINTENANCE

INSTRUCTIONS FOR ELEMENT REPLACEMENT CAUTION: Before installing your new elements, be sure the

Failure to do this may cause the immediate burnout of the new ele- ments.

All elements are thoroughly checked before shipment. The manu- facturer cannot be responsible for burnouts caused by a faulty low- water

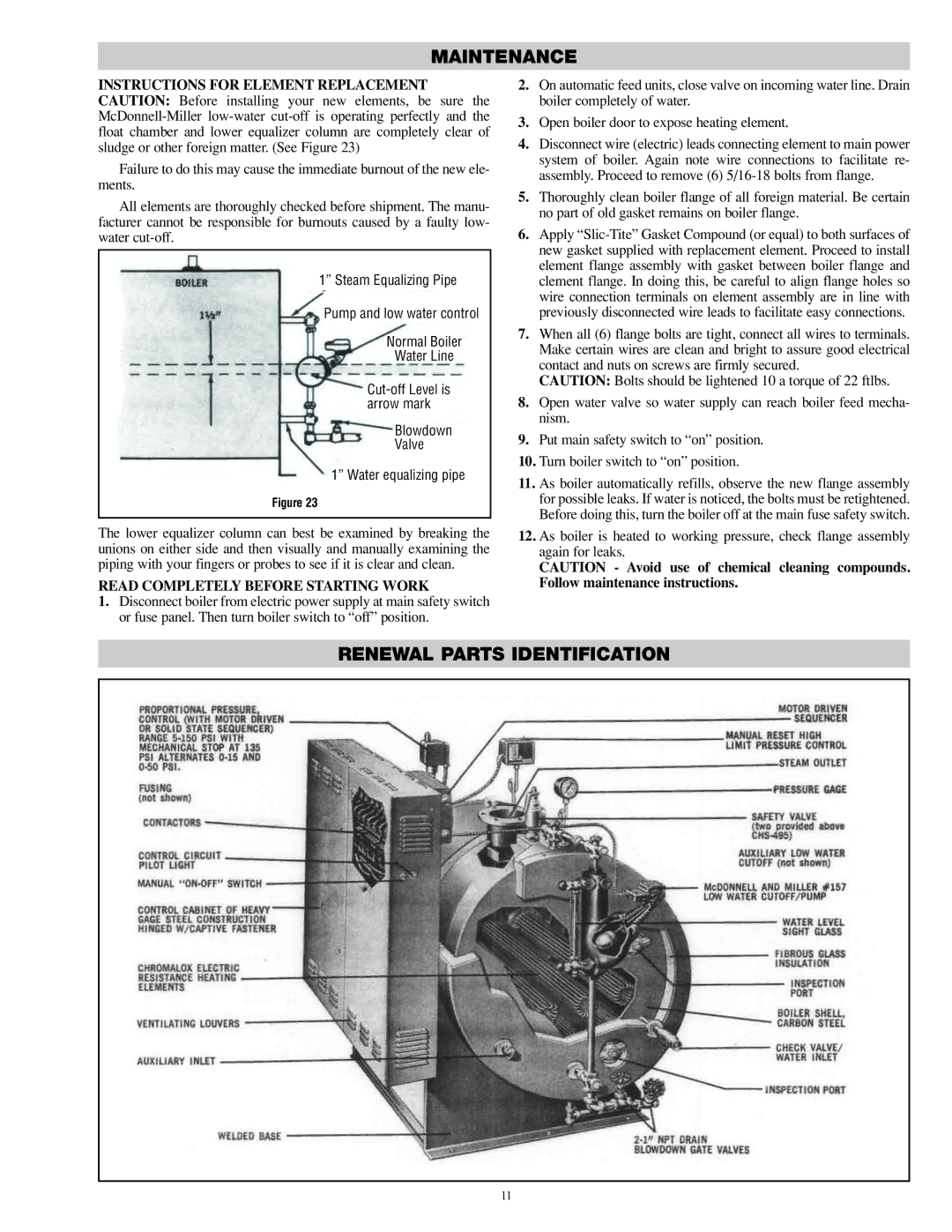

1” Steam Equalizing Pipe

Pump and low water control

Normal Boiler

Water Line

Blowdown

Valve

1” Water equalizing pipe

Figure 23

The lower equalizer column can best be examined by breaking the unions on either side and then visually and manually examining the piping with your fingers or probes to see if it is clear and clean.

READ COMPLETELY BEFORE STARTING WORK

1.Disconnect boiler from electric power supply at main safety switch or fuse panel. Then turn boiler switch to “off” position.

2.On automatic feed units, close valve on incoming water line. Drain boiler completely of water.

3.Open boiler door to expose heating element.

4.Disconnect wire (electric) leads connecting element to main power system of boiler. Again note wire connections to facilitate re- assembly. Proceed to remove (6)

5.Thoroughly clean boiler flange of all foreign material. Be certain no part of old gasket remains on boiler flange.

6.Apply

7.When all (6) flange bolts are tight, connect all wires to terminals. Make certain wires are clean and bright to assure good electrical contact and nuts on screws are firmly secured.

CAUTION: Bolts should be lightened 10 a torque of 22 ftlbs.

8.Open water valve so water supply can reach boiler feed mecha- nism.

9.Put main safety switch to “on” position.

10.Turn boiler switch to “on” position.

11.As boiler automatically refills, observe the new flange assembly for possible leaks. If water is noticed, the bolts must be retightened. Before doing this, turn the boiler off at the main fuse safety switch.

12.As boiler is heated to working pressure, check flange assembly again for leaks.

CAUTION - Avoid use of chemical cleaning compounds. Follow maintenance instructions.

RENEWAL PARTS IDENTIFICATION

11