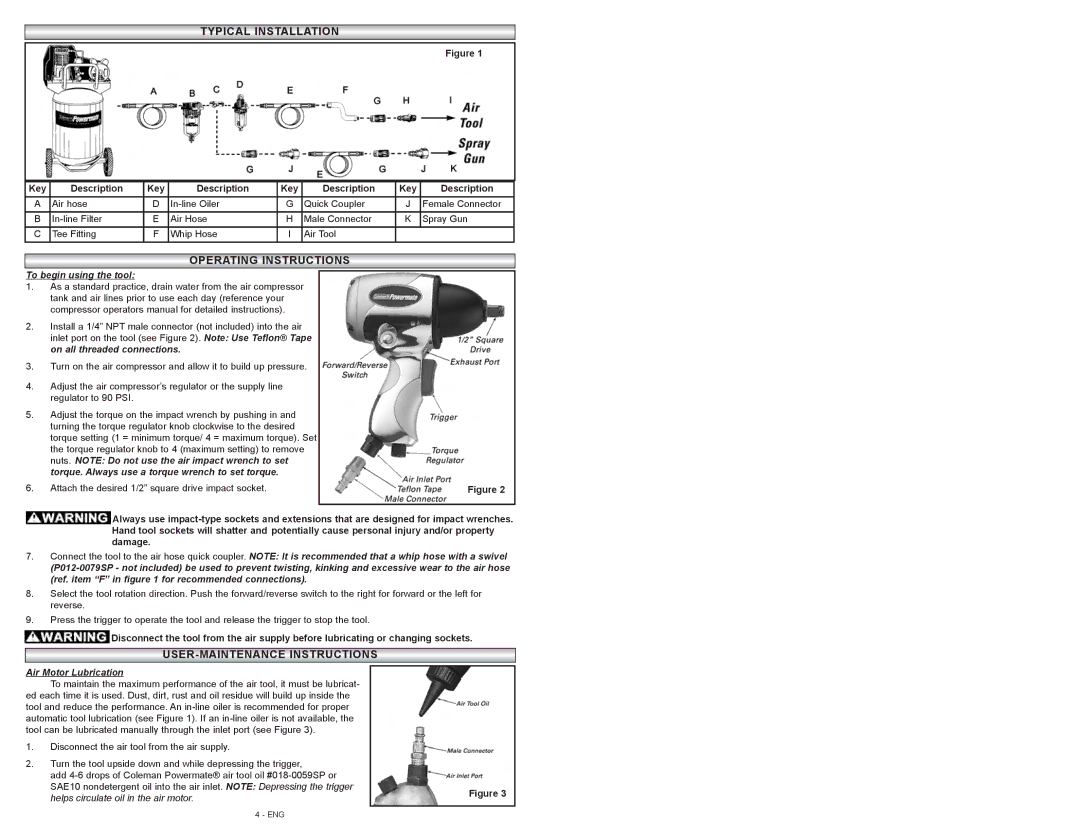

TYPICALTYPICAL INSTINSTALLAALLATIONTION

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Figure 1 | |

|

|

|

|

|

|

|

|

|

|

Key | Description | Key | Description | Key | Description | Key | Description | ||

A | Air hose | D | G | Quick Coupler | J | Female Connector | |||

B | E | Air Hose | H | Male Connector | K | Spray Gun | |||

C | Tee Fitting | F | Whip Hose | I | Air Tool |

|

|

|

|

OPERAOPERATINGTING INSTRUCTIONSINSTRUCTIONS

To begin using the tool:

1.As a standard practice, drain water from the air compressor tank and air lines prior to use each day (reference your compressor operators manual for detailed instructions).

2.Install a 1/4” NPT male connector (not included) into the air inlet port on the tool (see Figure 2). Note: Use Teflon® Tape on all threaded connections.

3.Turn on the air compressor and allow it to build up pressure.

4.Adjust the air compressor’s regulator or the supply line regulator to 90 PSI.

5.Adjust the torque on the impact wrench by pushing in and turning the torque regulator knob clockwise to the desired torque setting (1 = minimum torque/ 4 = maximum torque). Set the torque regulator knob to 4 (maximum setting) to remove nuts. NOTE: Do not use the air impact wrench to set torque. Always use a torque wrench to set torque.

6. | Attach the desired 1/2” square drive impact socket. |

|

Figure 2 |

![]() Always use

Always use

7.Connect the tool to the air hose quick coupler. NOTE: It is recommended that a whip hose with a swivel

8.Select the tool rotation direction. Push the forward/reverse switch to the right for forward or the left for reverse.

9.Press the trigger to operate the tool and release the trigger to stop the tool.

![]() Disconnect the tool from the air supply before lubricating or changing sockets.

Disconnect the tool from the air supply before lubricating or changing sockets.

USER-MAINTENANCE INSTRUCTIONSSTRUCTIONS

Air Motor Lubrication

To maintain the maximum performance of the air tool, it must be lubricat- ed each time it is used. Dust, dirt, rust and oil residue will build up inside the tool and reduce the performance. An

1.Disconnect the air tool from the air supply.

2.Turn the tool upside down and while depressing the trigger,

add

Figure 3

4 - ENG