PW0923500, Powermate specifications

The Coleman PW0923500, also known as the Powermate, is a versatile and reliable pressure washer designed to tackle various cleaning tasks with ease. Known for its powerful performance and user-friendly features, the Powermate is an ideal choice for homeowners and professionals alike.One of the standout characteristics of the Coleman PW0923500 is its robust engine. Powered by a durable 212cc gasoline engine, it delivers an impressive 2900 PSI (pounds per square inch) of cleaning power, making it effective for removing tough grime, dirt, and stains from various surfaces. Additionally, the unit boasts a flow rate of 2.5 GPM (gallons per minute), ensuring a steady supply of water for efficient cleaning.

The design of the Powermate is both rugged and practical. Equipped with a 25-foot high-pressure hose, it provides ample reach for cleaning driveways, patios, siding, and vehicles without the need to move the unit frequently. The pressure washer also features a durable, powder-coated steel frame that enhances its durability, allowing it to withstand the rigors of outdoor use.

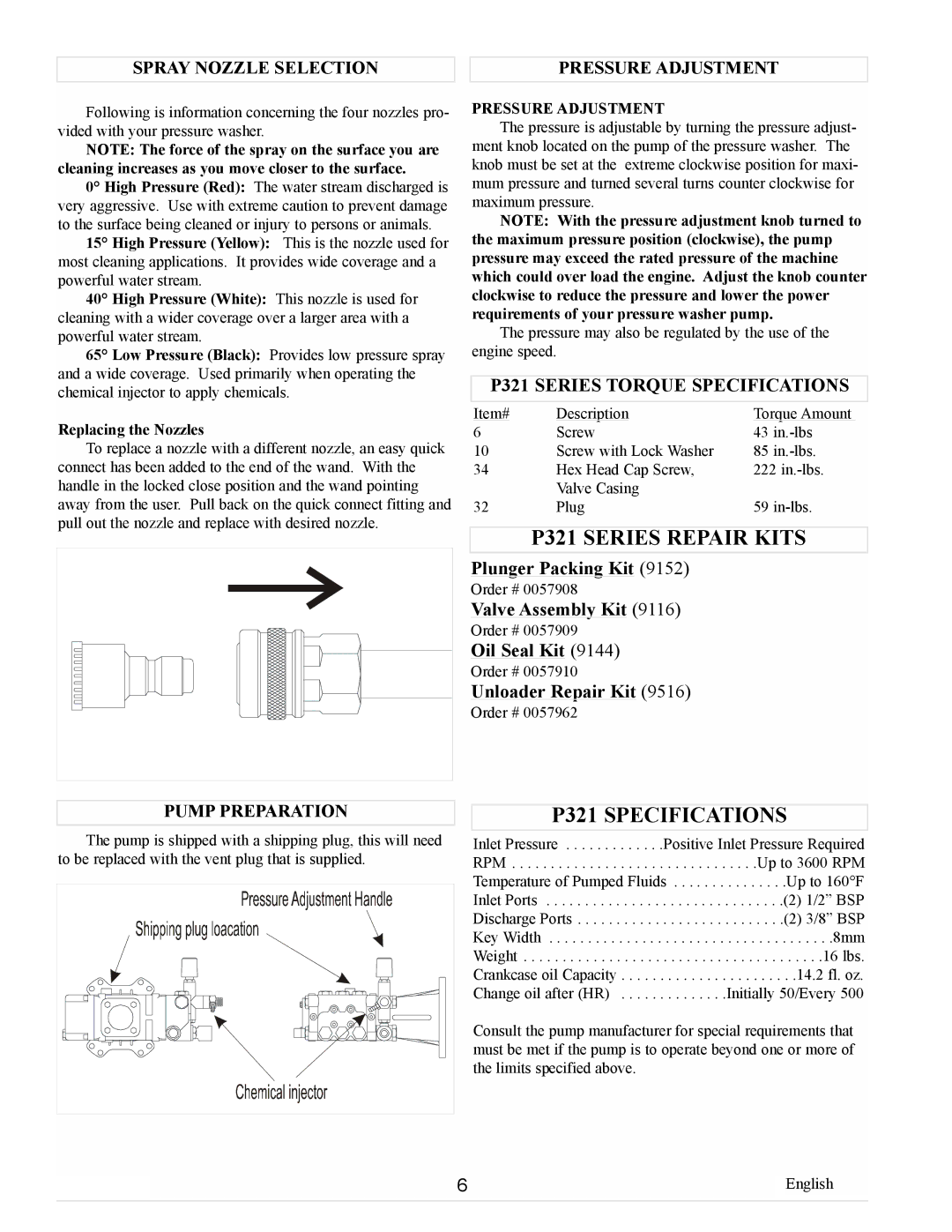

For versatility, the Coleman PW0923500 comes with four interchangeable nozzles. These nozzles allow users to switch between different spray patterns, enabling tailored cleaning for various surfaces. The quick-connect feature simplifies nozzle changes, making the transition between tasks seamless.

In terms of technology, the unit includes a built-in detergent tank that facilitates the application of soap for more effective cleaning. This feature is particularly useful for dealing with stubborn stains and heavy dirt, as it allows for pre-soaking and enhances the overall cleaning process.

Safety and ease of use are prioritized in the design of the Powermate. The pressure washer includes a safety trigger with a lock-off feature to prevent accidental operation. Additionally, the generous pneumatic tires enhance mobility, making it easy to maneuver over uneven terrain.

In conclusion, the Coleman PW0923500 Powermate pressure washer combines power, durability, and innovation, making it an excellent tool for various cleaning tasks. With its strong engine, multiple nozzles, and user-friendly features, it delivers an efficient and effective cleaning solution for both everyday homeowners and professional users. Whether you need to clean your driveway or prepare your deck for staining, the Powermate is a reliable companion for every cleaning project.